Sensor for temperature and heat-flow measuring under high temperature environment

A high-temperature environment and sensor technology, applied in the field of sensors, can solve problems such as inability to meet long-term measurement and measurement requirements, and achieve the effects of reducing heat radiation, hindering gas convection, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

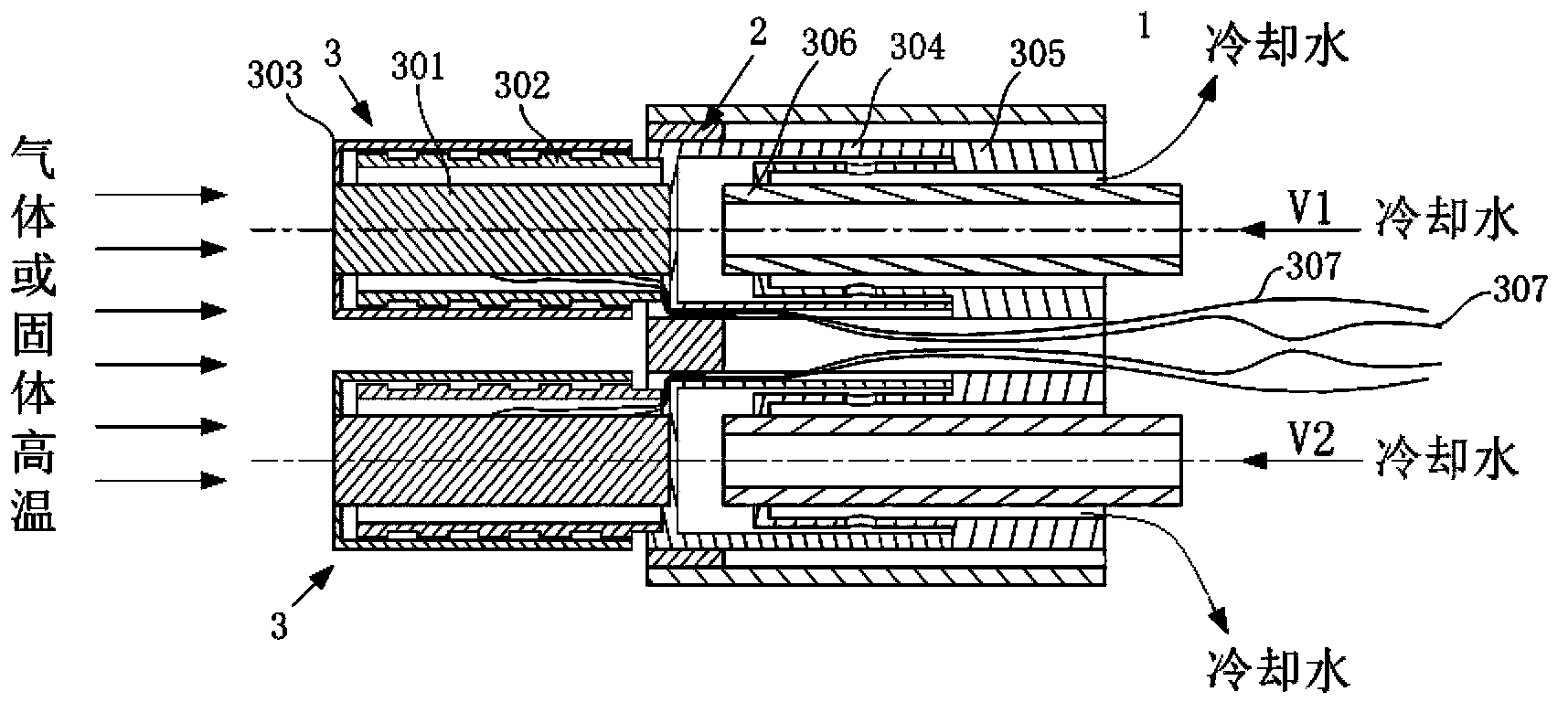

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

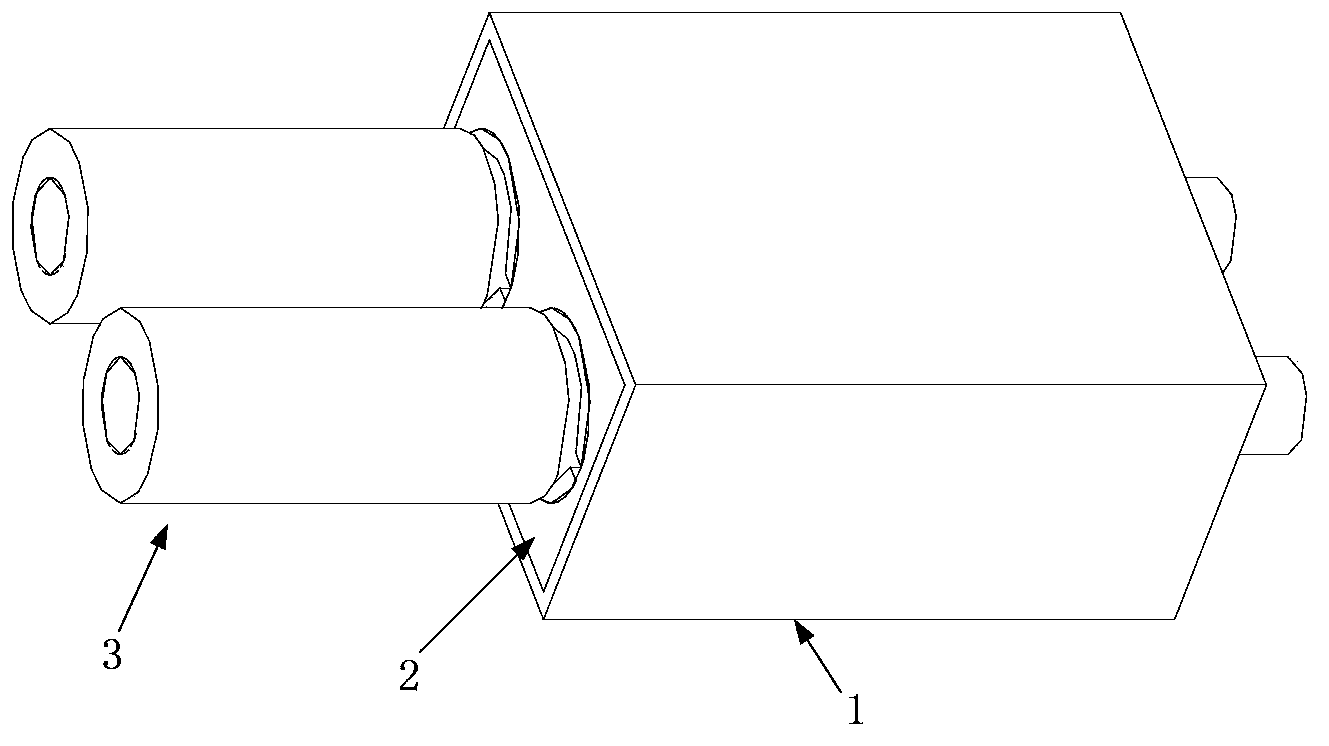

[0022] The temperature and heat flow measurement sensor of the present invention includes a protective shell 1, a fixed base 2, and a measuring column 301, a thermal insulation inner sleeve 302, a thermal insulation outer jacket 303, a cooling jacket 304, a water outlet pipe 305, a water inlet pipe 306 and two thermocouples. 307 constitute the measurement component 3;

[0023] The protective shell 1 has a cylindrical structure, and a fixed base 2 is installed on the front end, and two mounting holes are opened on the fixed base 2 . There are two sets of measuring components 3, and one set of measuring components 3 is installed in the same way at each mounting hole. Taking a set of measuring assembly 3 as an example, the structure and installation method of the measuring assembly 3 in the present invention are described:

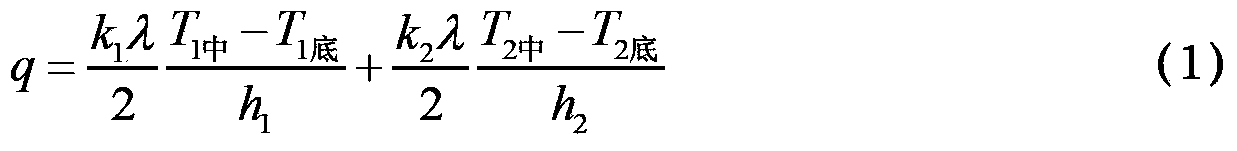

[0024] The cooling jacket 304 in the measurem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap