Steaming tool and food steaming method

A technology for steaming utensils and food, which is applied in the fields of cyclically steaming food, self-service, and steaming food, and can solve the problems of uncontrollable food raw material safety and sanitation, poor freshness, steam leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

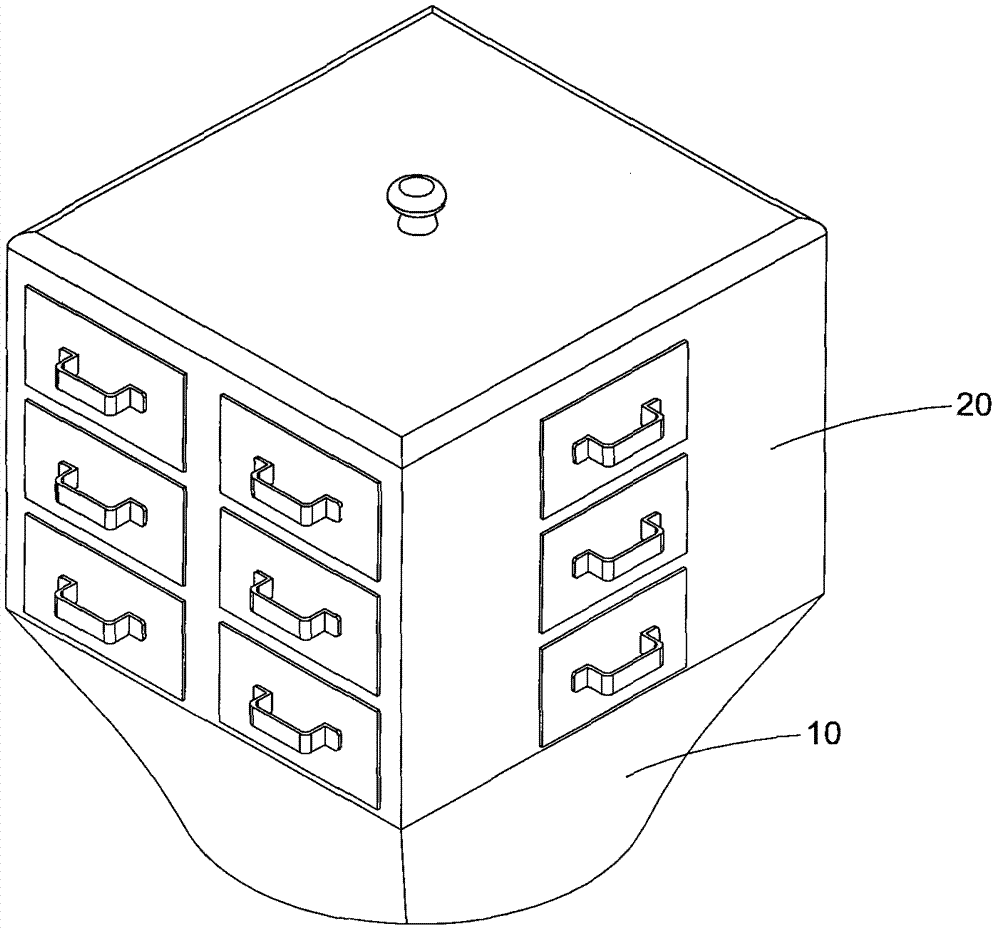

[0040] Such as figure 1 As shown, the steamer of the present invention includes a first cavity 10 and a second cavity 20 communicating with the first cavity, wherein the first cavity 10 is used to hold liquid water , the food material to be steamed is contained in the second cavity 20, and by heating the first cavity 10, the liquid water in it is converted into steam and enters the second cavity 20, so that the The food raw materials in the second cavity 20 are steamed.

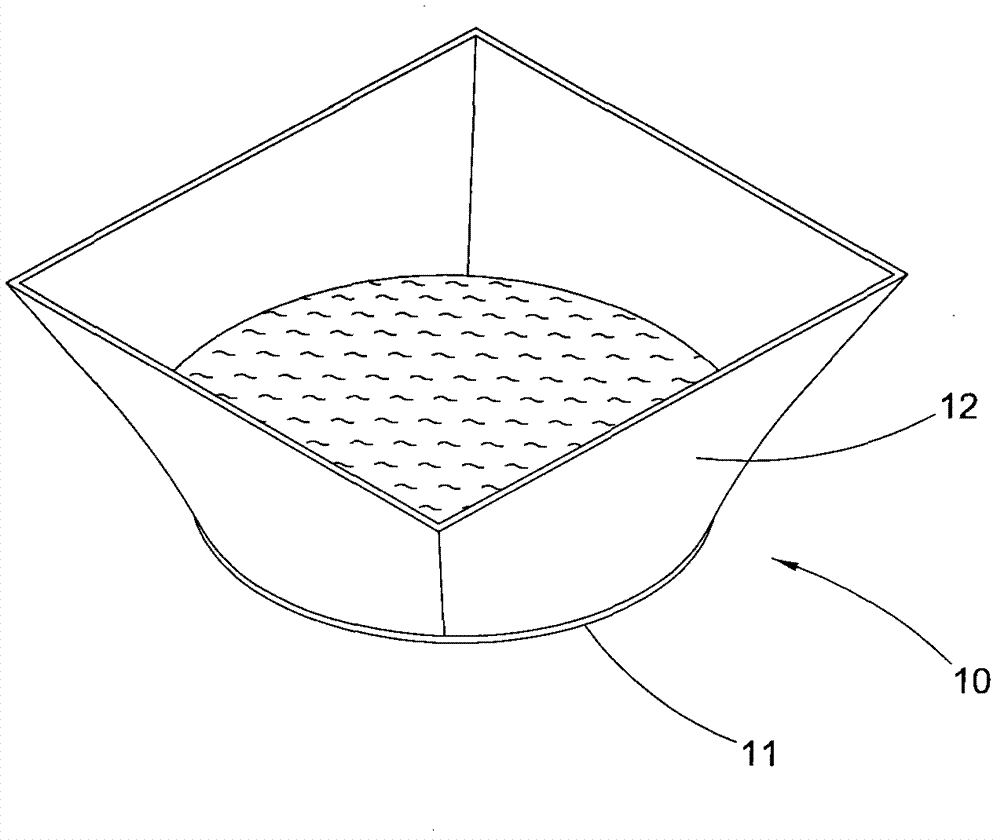

[0041] Such as figure 2 As shown, the first cavity 10 has a bottom wall 11 and a side wall 12. Preferably, the bottom wall 11 is flat and made of iron material so as to be placed on an induction cooker for heating to save space for the entire steamer. Since the steamer of the present invention is mainly used for self-service steaming food, its shape should not be too large so that it can be placed on the dining table to facilitate the operation of eaters. There is a valve 121 (not shown in the figure) on...

Embodiment 2

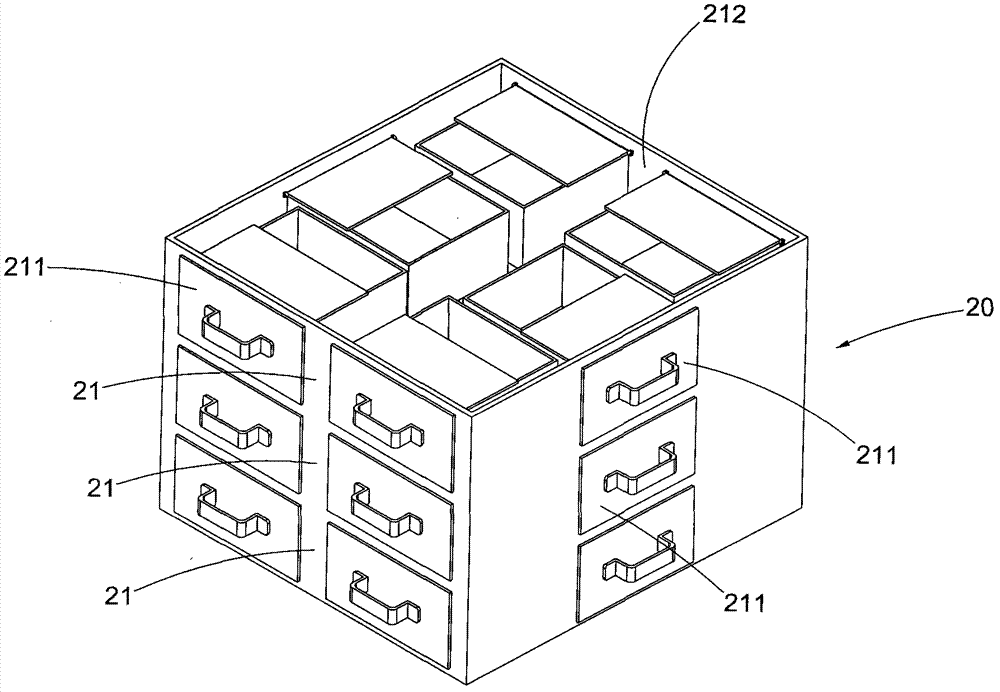

[0052] Figure 6 to Figure 8 A second embodiment of the steamer according to the invention is shown. The second embodiment is improved on the basis of the first embodiment, and its structure is basically the same as that of the first embodiment, except that each vaporized layer body 21 in the second cavity 20 is also isolated from each other.

[0053] Such as Figure 6 As shown, the steamer further includes a guide pipe 30 for guiding water vapor from the first cavity 10 into the second cavity 20, that is to say, the first cavity 10 and the second cavity The two cavities 20 communicate with each other through the guide tube 30 .

[0054] Such as Figure 7 As shown, the guide pipe 30 is arranged at the upper end of the first cavity 20 and runs through all the evaporated layers 21 of the second cavity 20 . A group of air guide holes 301 are arranged at intervals on the side wall of the guide pipe 30, and the number of the air guide holes 301 is equal to the number of the ste...

Embodiment 3

[0059] Figure 9 to Figure 1 2 shows a third embodiment of the steamer according to the present invention. The third embodiment is improved on the basis of the second embodiment. In the second embodiment, the steamed layer bodies 21A of the second cavity 20 are isolated from each other and do not communicate with each other, that is to say, the water vapor directly enters the steamed layer bodies 21A from the first cavity 10 respectively. Yes, in the third embodiment, water vapor directly enters each steaming tray 211B of each steaming layer body 21B directly from the first cavity 10 through a set of guide pipes 30B, that is to say, each steaming tray is A small steaming unit, that is, the steamer has multiple steaming units at the same time, and each steaming unit steams independently without interfering with each other.

[0060] Such as Figure 9 As shown, the second cavity 20 of the steamer in this embodiment includes two layers of steamed layers 21B stacked in sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com