Mechanical and automatic wire inserting mechanism

An automatic and mechanical technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to meet the requirements of use, and achieve the effect of saving space, liberating productivity, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

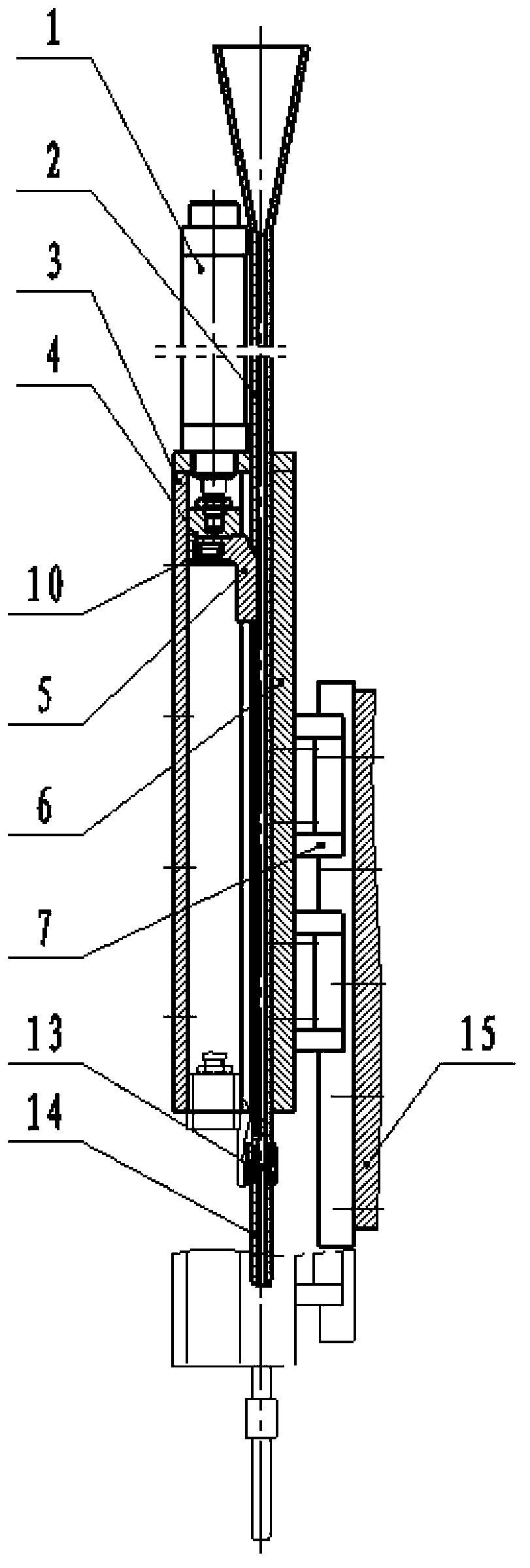

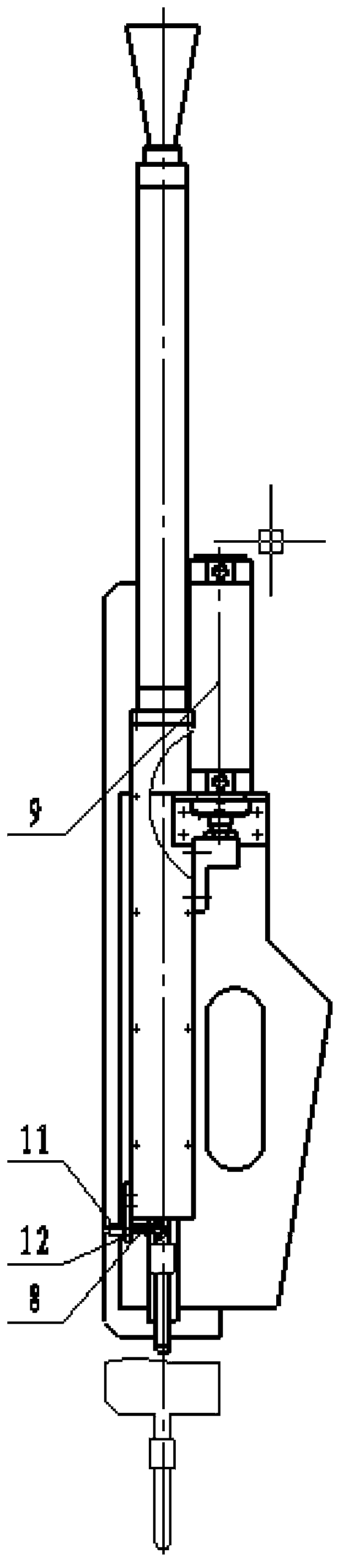

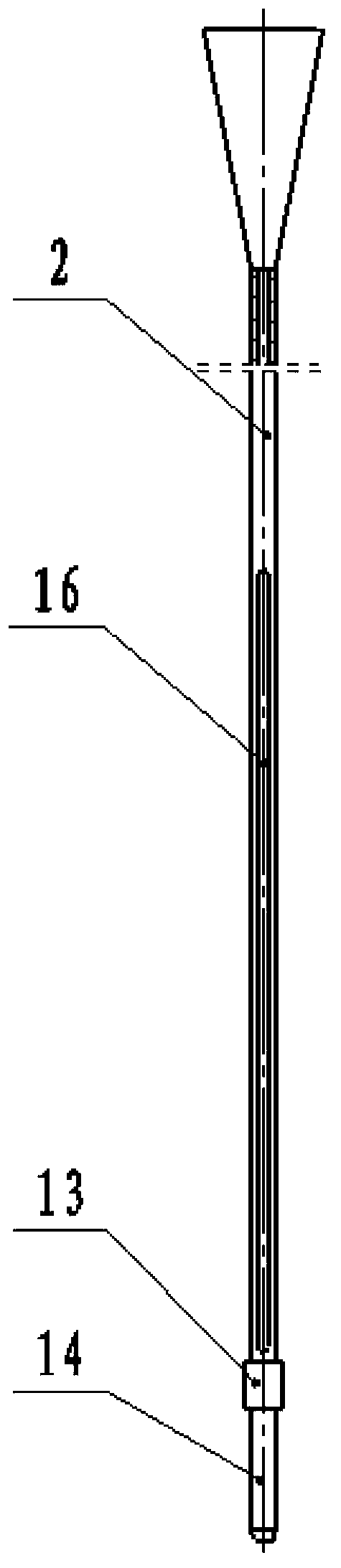

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] figure 1 , figure 2 , the structural features of the mechanical automatic wire insertion mechanism of the present invention shown, including: a wire insertion cylinder 1 and a guide tube 2 arranged in parallel, a guide seat 6 that fixes the wire insertion cylinder 1 and the guide tube 2, and a supporting structure thereof Guide plate 3, guide slider 4 is set on the wire insertion cylinder 1, and push rod 5 and push rod spring 10 are arranged on the guide slider 4, and guide slider 4 is driven along the guide seat 6 under the drive of wire insertion cylinder 1. The slider guide groove 17 performs reciprocating linear motion to form a wire insertion unit; the guide seat 6 is also provided with a displacement cylinder 9, and is connected to the fixed frame of the overall equipment through the linear guide rail pair 7;

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com