Truss omnibearing welding overturning platform

An all-round, flipping table technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of danger, time-consuming, difficult flipping, etc., and achieve easy flipping, convenient welding, and high safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

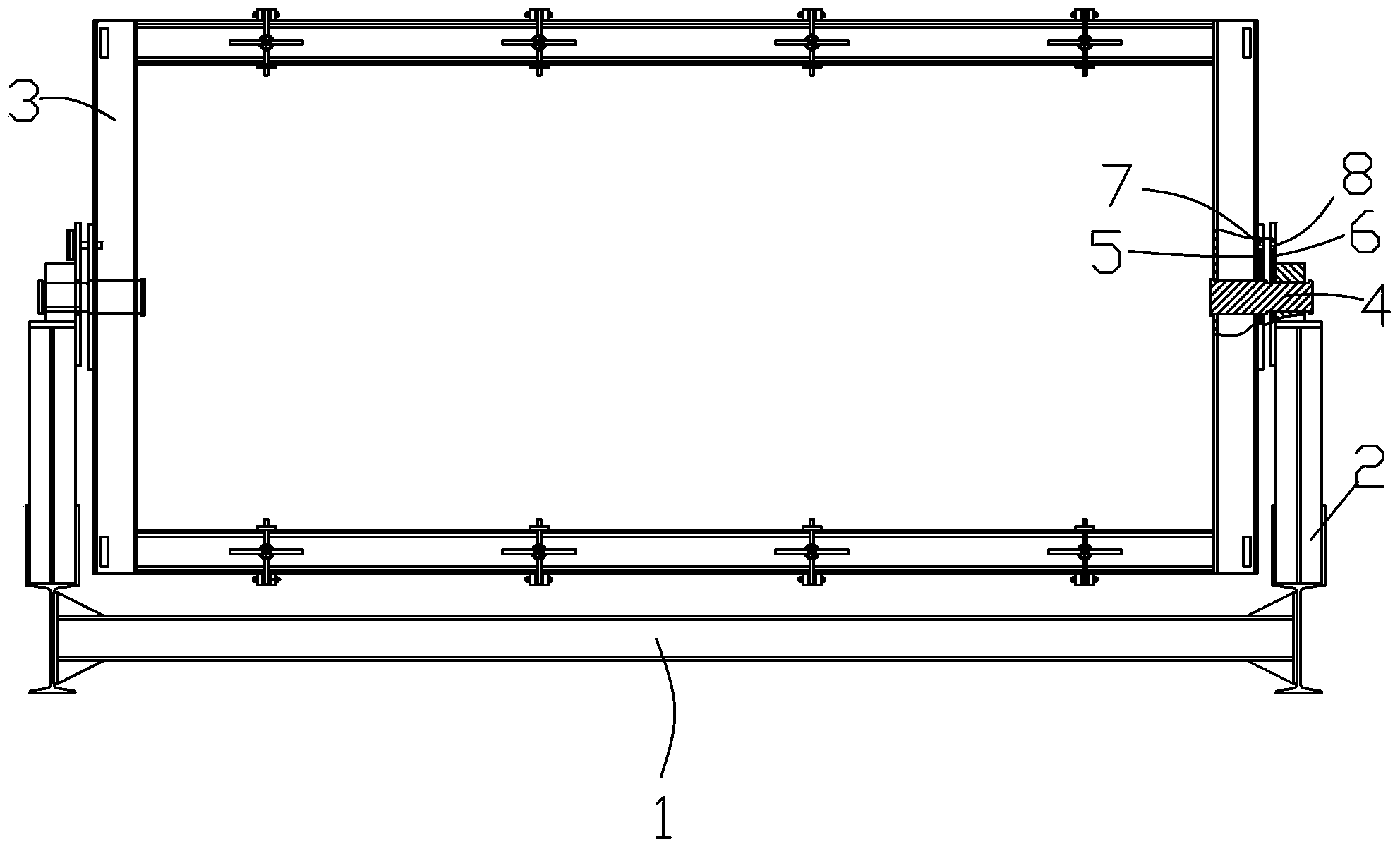

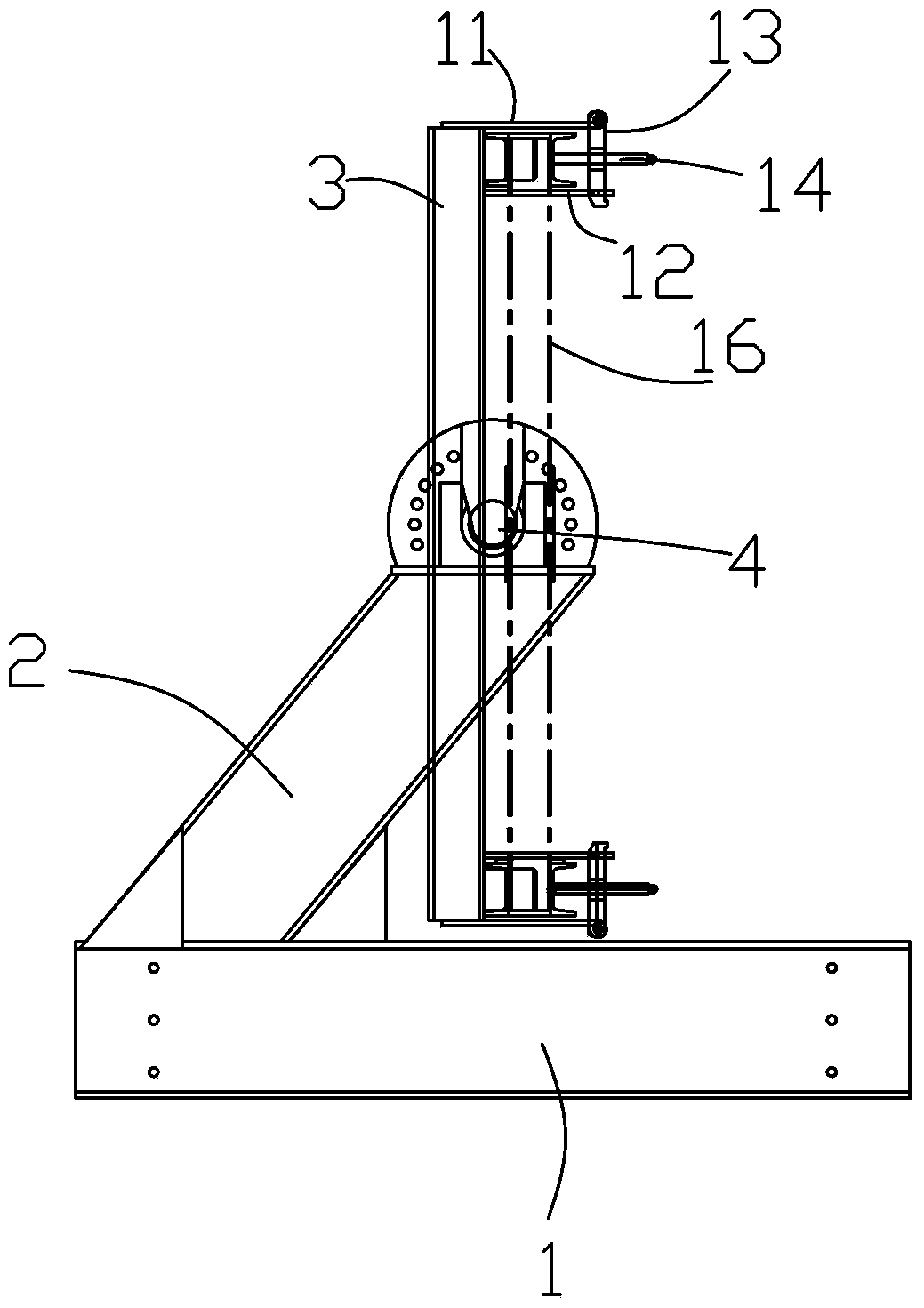

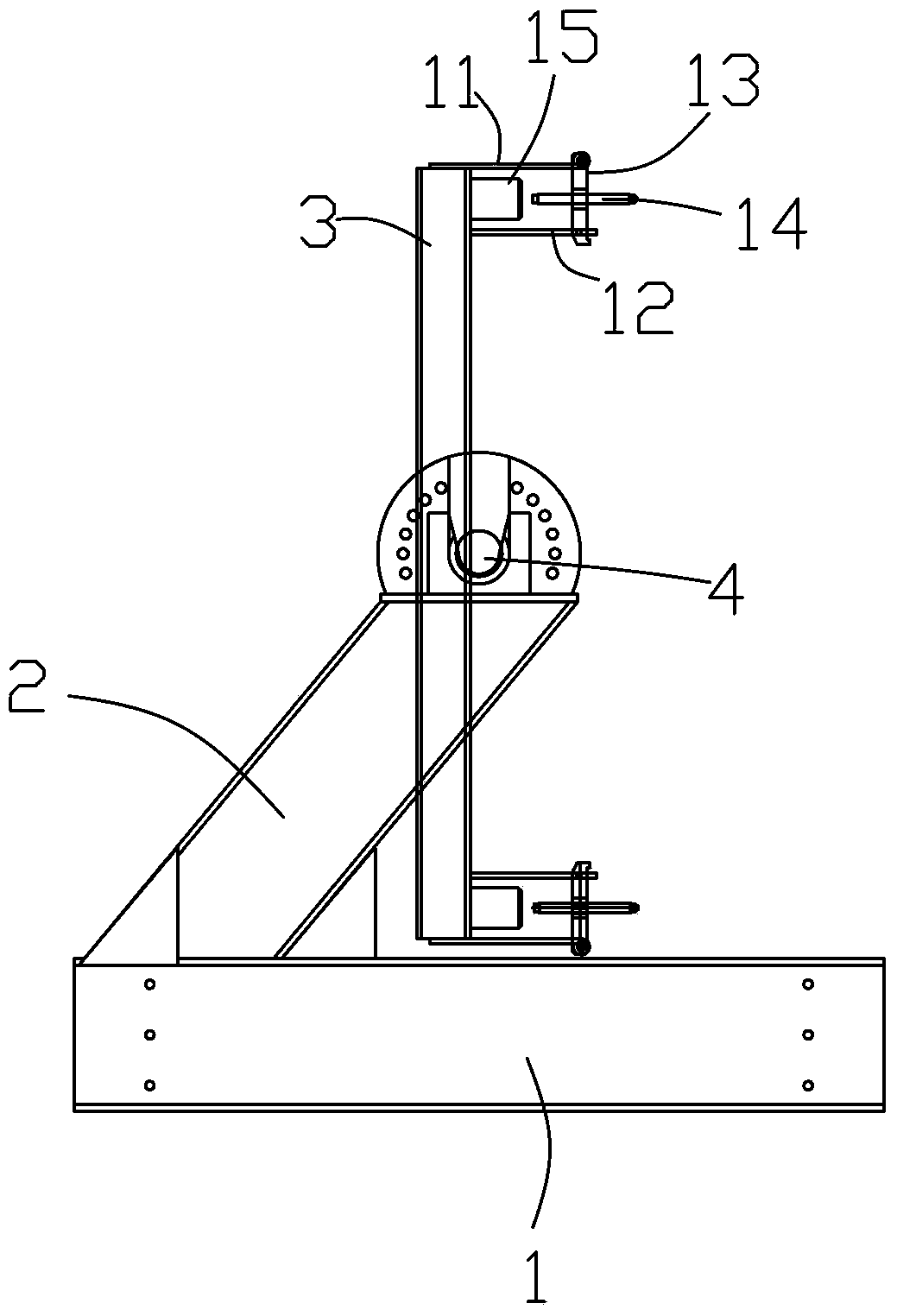

[0019] refer to Figure 1 to Figure 6 , the invention discloses a truss omni-directional welding turning platform, comprising a base 1, on which a support arm 2 is oppositely arranged, and a workbench 3 is arranged between the support arms 2, and the workbench 3 is connected to the support arm 2 through a pivot 4 Pivot connection, the support arm 2 is inclined to form an angle of forty-five degrees with the base 1, so the workbench 3 can just be located directly above the base 1, and a number of fixtures for fastening the truss welding workpiece 16 are arranged on the workbench 3, and the working A locking mechanism for locking the worktable 3 is provided between the table 3 and the support arm 2 .

[0020] As shown in the figure, the locking mechanism includes a positioning plate 5 arranged on one side of the workbench 3 and a fixing plate 6 arranged on the support arm 2. The positioning plate 5 rotates together with the workbench 3, and the positioning plate 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com