Medicine slicing machine

A cutting machine and medicinal material technology, applied in metal processing and other directions, can solve the problems of large pieces and strips, large area, inconvenient use, etc., and achieve the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

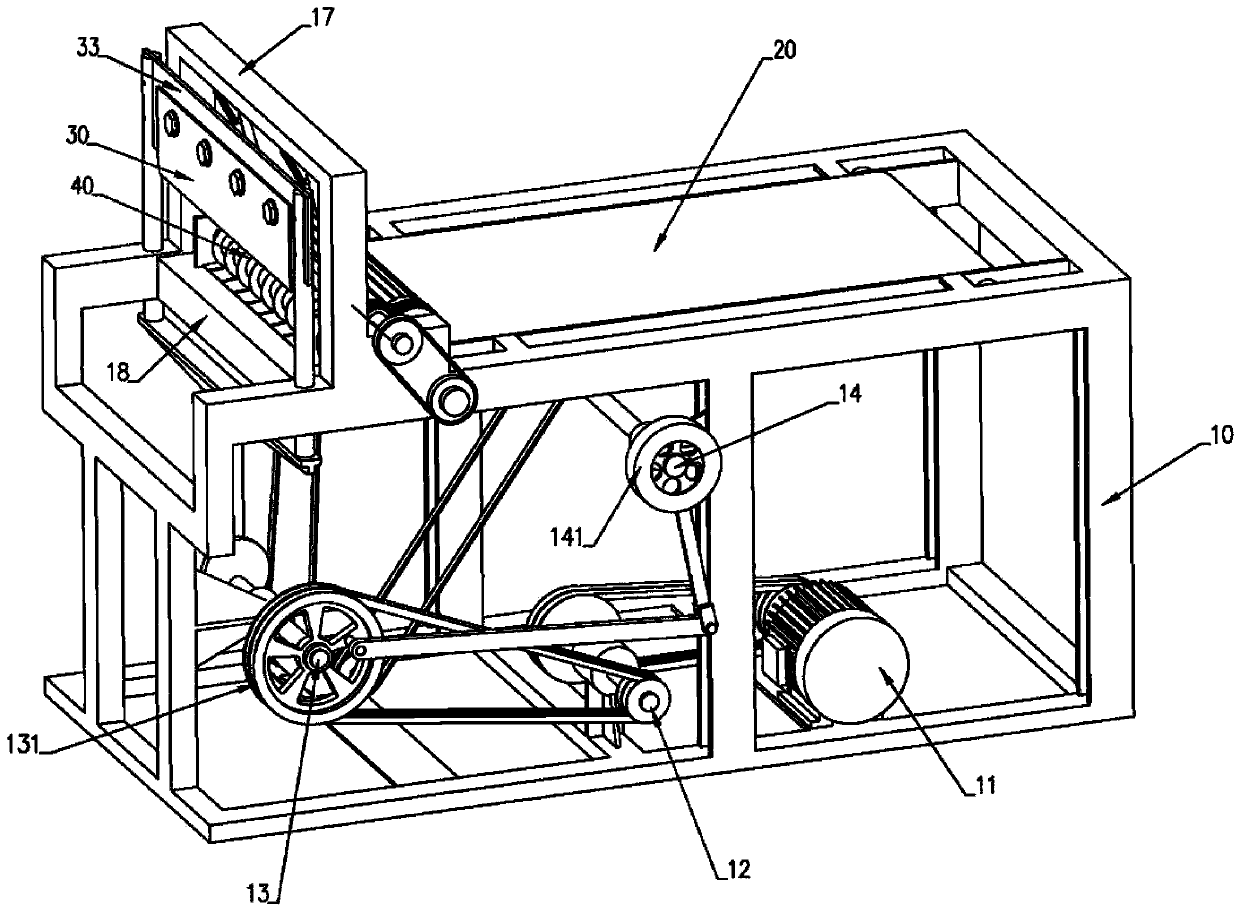

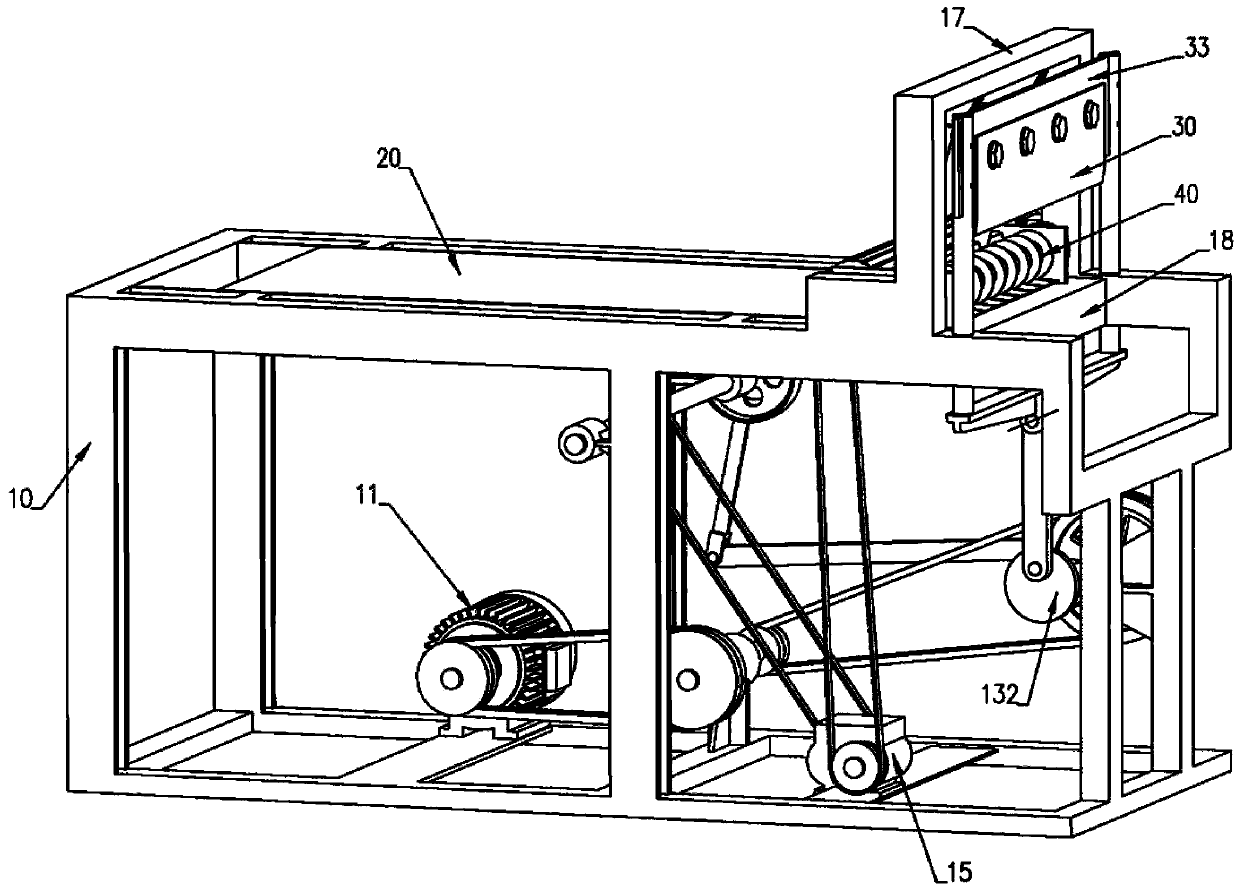

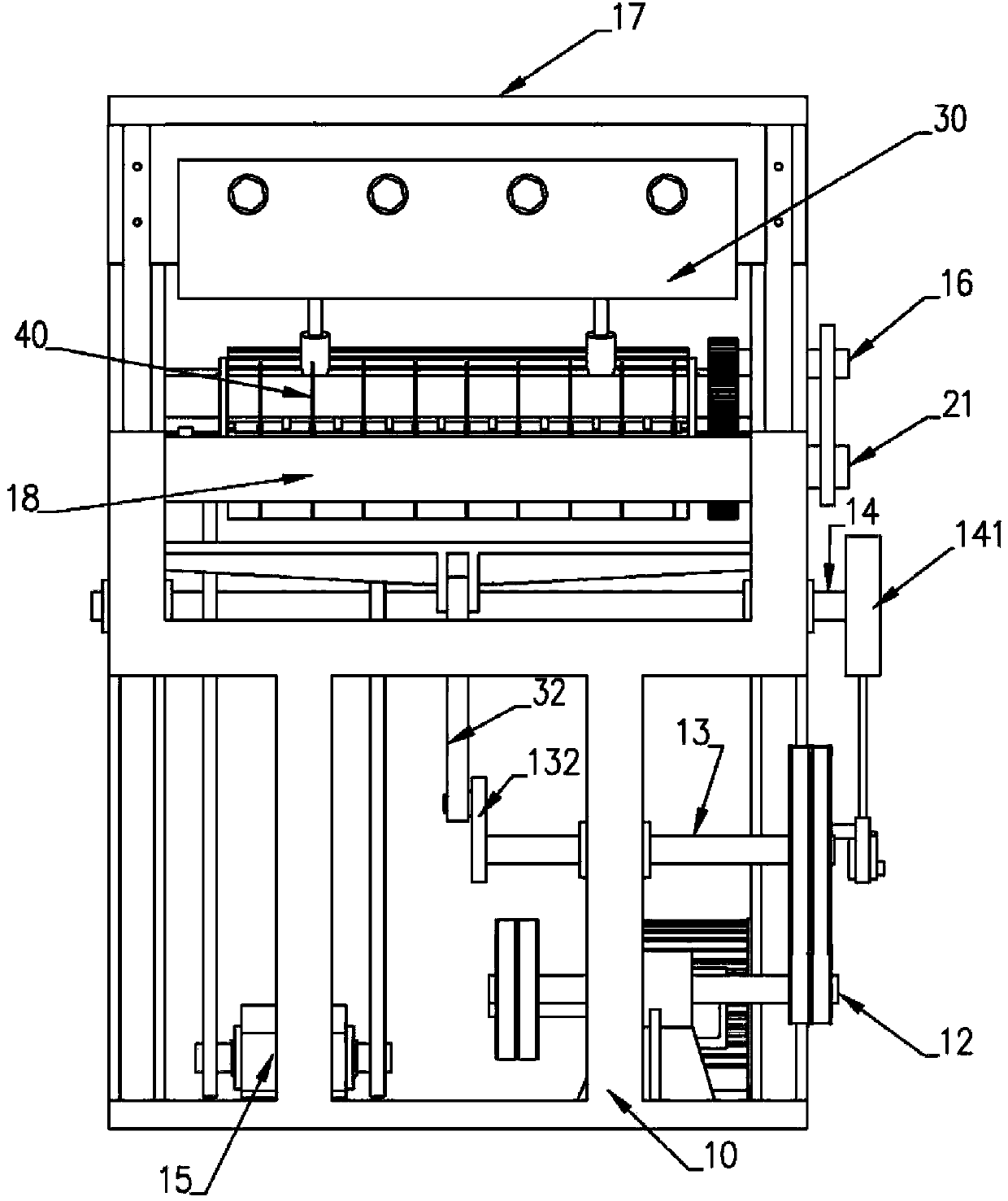

[0013] like figure 1 , 2 A kind of medicinal material cutting machine shown, comprises the conveyer belt 20 that is arranged on the frame 10 along the horizontal direction, the first cutting tool 30 that cutting direction is perpendicular to the conveying direction of conveyer belt 20, is characterized in that: frame 10 also has A second cutting tool 40 is provided, the first cutting tool 30 and the second cutting tool 40 are located at the discharge end of the conveyor belt 20, and the cutting directions of the first cutting tool 30 and the second cutting tool 40 cross each other A feeding mechanism is provided between the combined cutting tool formed by the first cutting tool 30 and the second cutting tool 40 and the discharge end of the conveyor belt 20 . Since the cutting directions of the first cutting knife 30 and the second cutting knife 40 intersect each other, it can be ensured that medicinal material of any shape can be cut into small pieces instead of being cut int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com