Wood meal gluing feeding device

A technology of feeding device and conveying device, which is applied in the direction of wood processing equipment, pretreatment of molding materials, manufacturing tools, etc., can solve the problems of low production efficiency, high production cost, and high defective rate of toilet lids, and achieve shortened processing Cycle time, the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

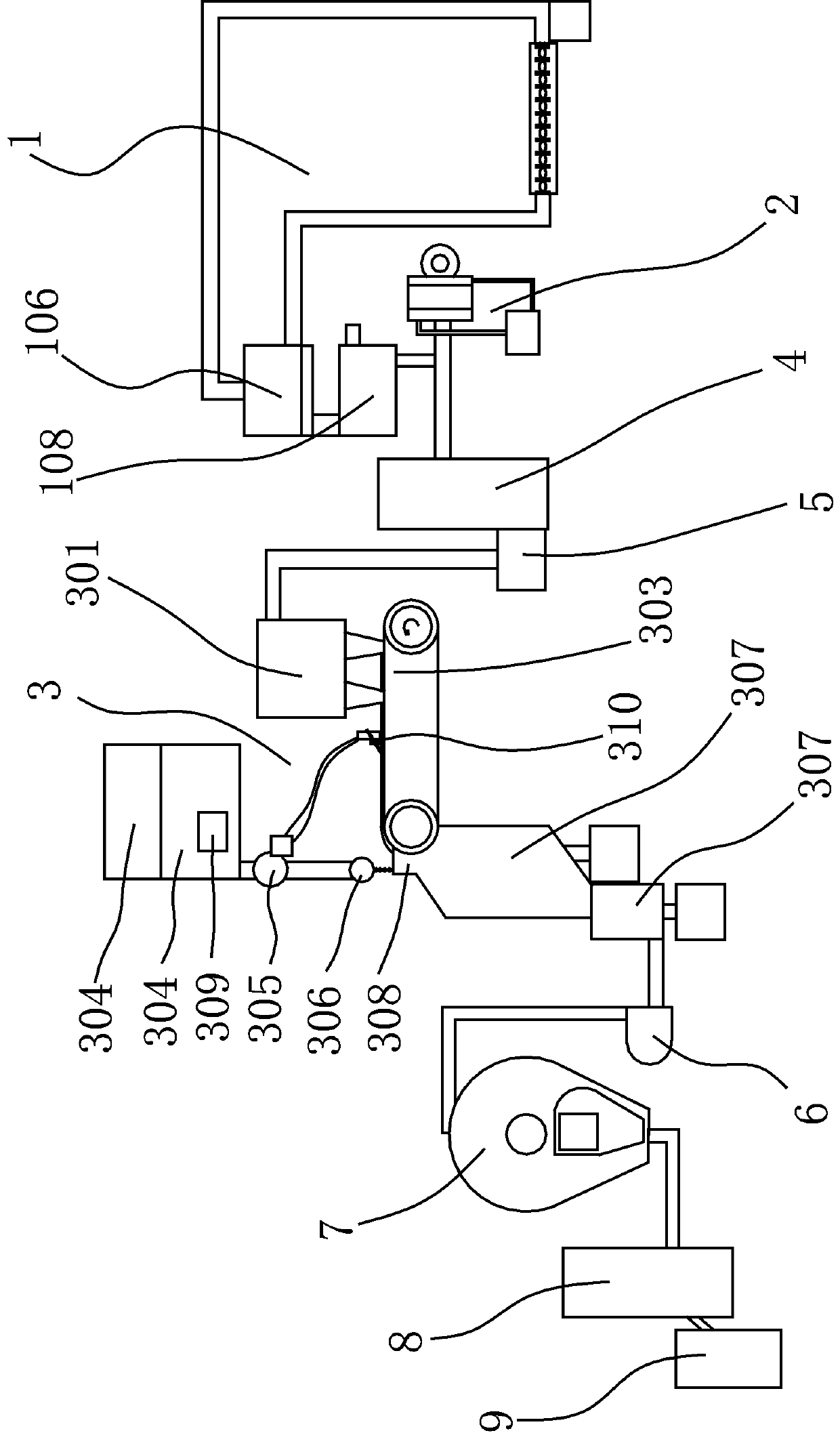

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 8 A wood powder gluing and feeding device includes a wood powder pretreatment conveying device 1, a wood powder pretreatment drying device 2, and a wood powder pretreatment gluing device 3.

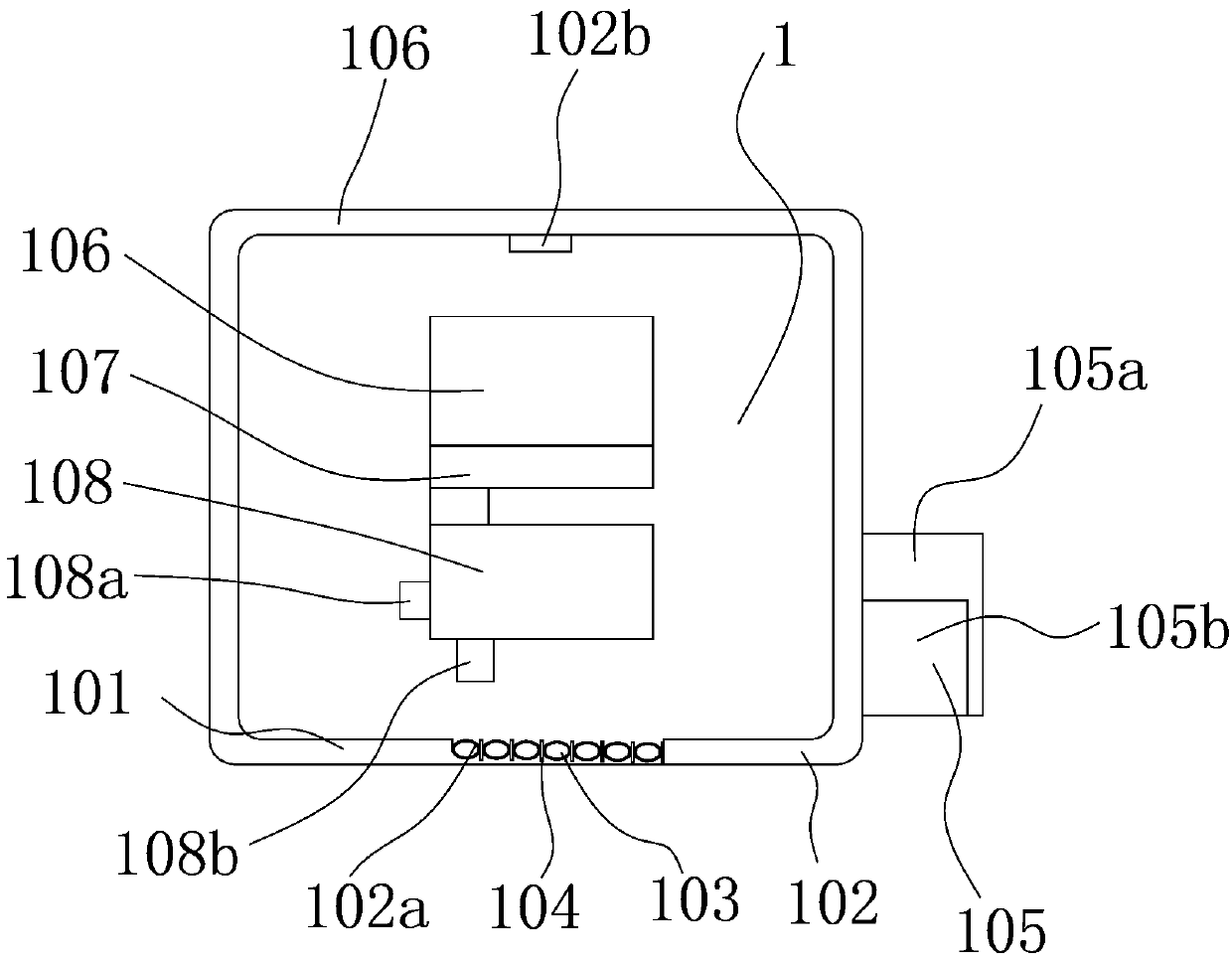

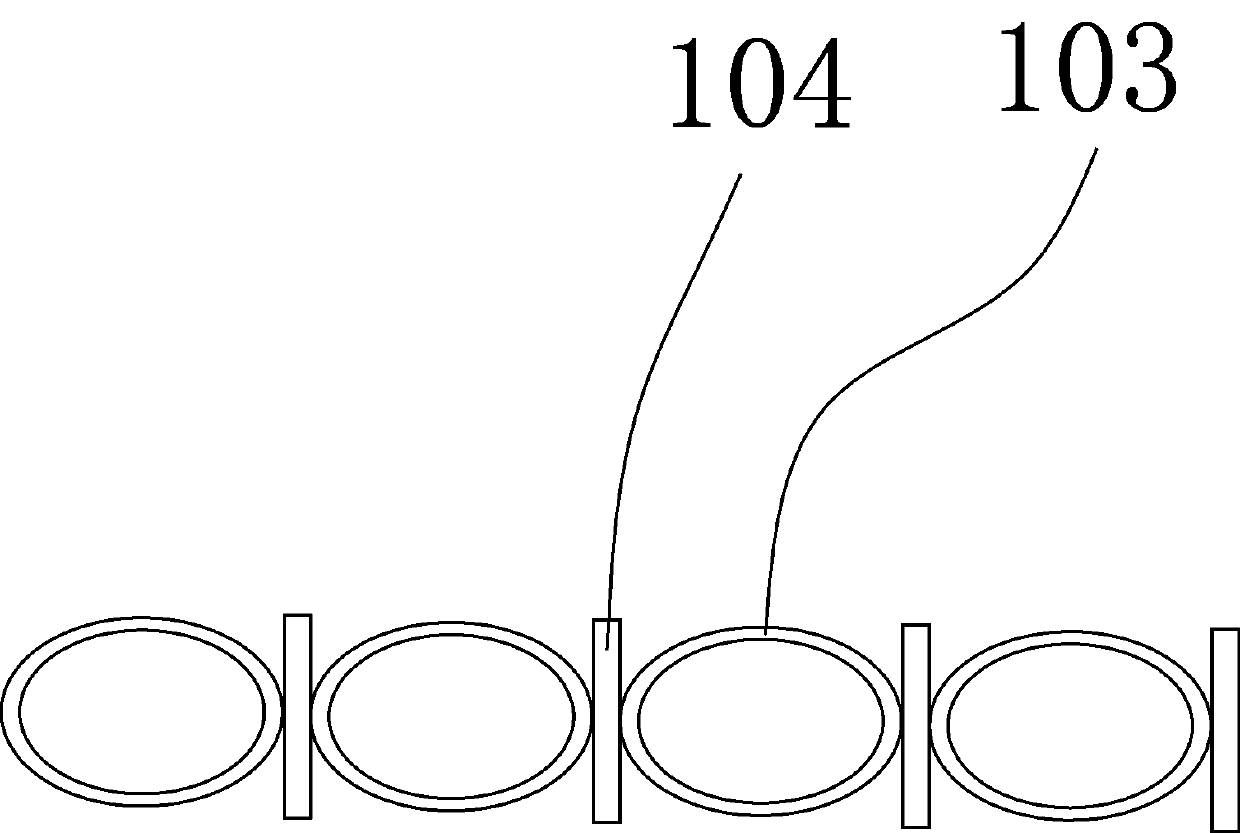

[0019] The wood powder pre-treatment conveying device 1 includes a feeding system 101, the feeding system 101 includes a pipe 102 connected end to end, the pipe 102 is provided with a chain 103 connected end to end, and the chain 103 is provided with a Several circular plates 104 matching the diameter of the pipeline 102, the pipeline 102 is provided with a first material inlet 102a, a first material outlet 102b and a driving device 105, and the driving device 105 includes a sprocket 105a and a first The motor 105b, the sprocket 105a is matched with the chain 103 . When the feeding system is in use, workers put wood flour into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com