Preparation method of foam product

A product and foam technology, which is applied in the field of foam product preparation, can solve the problems of inapplicability to industrial production, cumbersome processing process, and increased risk, and achieve the effects of easy operation and control, simple processing process, and no waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

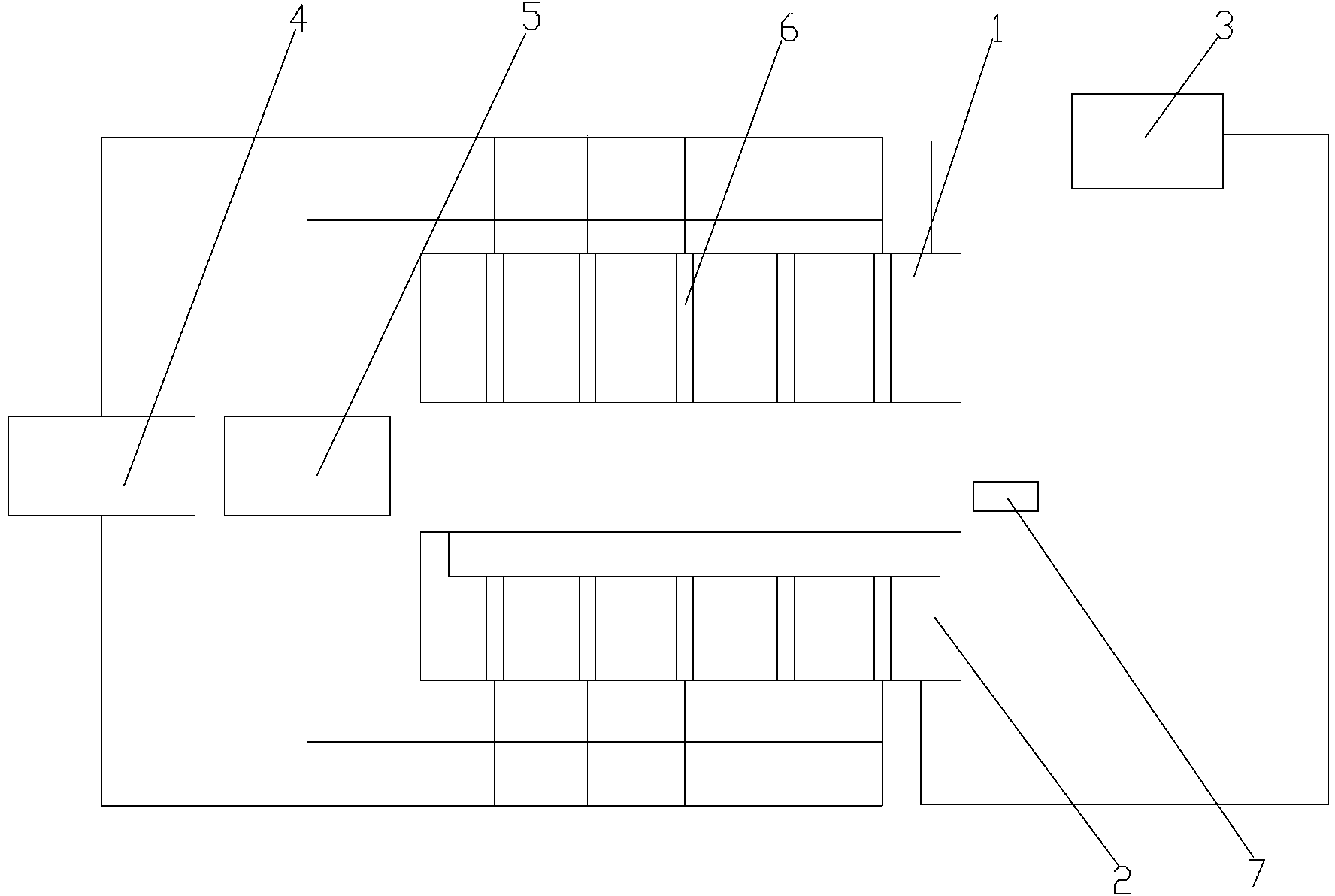

[0012] attached figure 1 In the method for preparing foam products described in the present invention, a molding press is used, and the molding press has an upper die 1, a lower forming die 2, a control system 3, a cooling system 4, and a steam system 5; Die 1, lower forming die 2, upper cooling system 4, and steam system 5 are electrically connected; said upper die 1 and lower forming die 2 are respectively provided with ventilation holes 6 communicating with upper cooling system 4 and steam system 5; The upper die 1 can move towards and away from the direction of the lower forming die 2; the upper die 1 moves downward to a distance of 4-5 mm from the lower forming die to be provided with a proximity switch 7; the proximity switch 7 is electrically Connect the control system 3. During production and processing, firstly, the upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com