Numerically controlled jadeware engraving, milling and polishing machine tool

A technology of engraving and milling machine and honing machine is applied in the field of numerical control machine tools, which can solve the problems of low efficiency, high work intensity and high cost, and achieve the effect of reducing cost and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

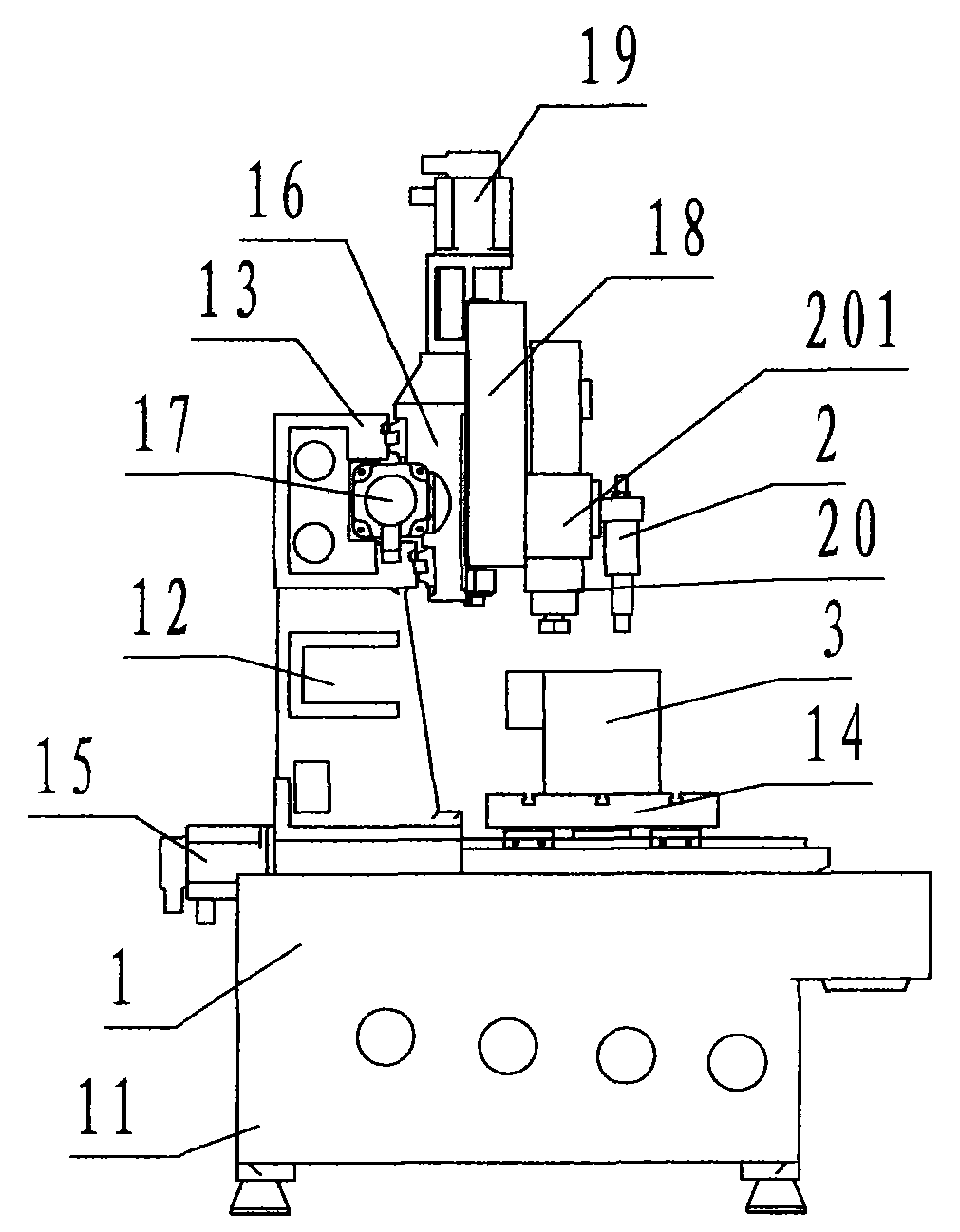

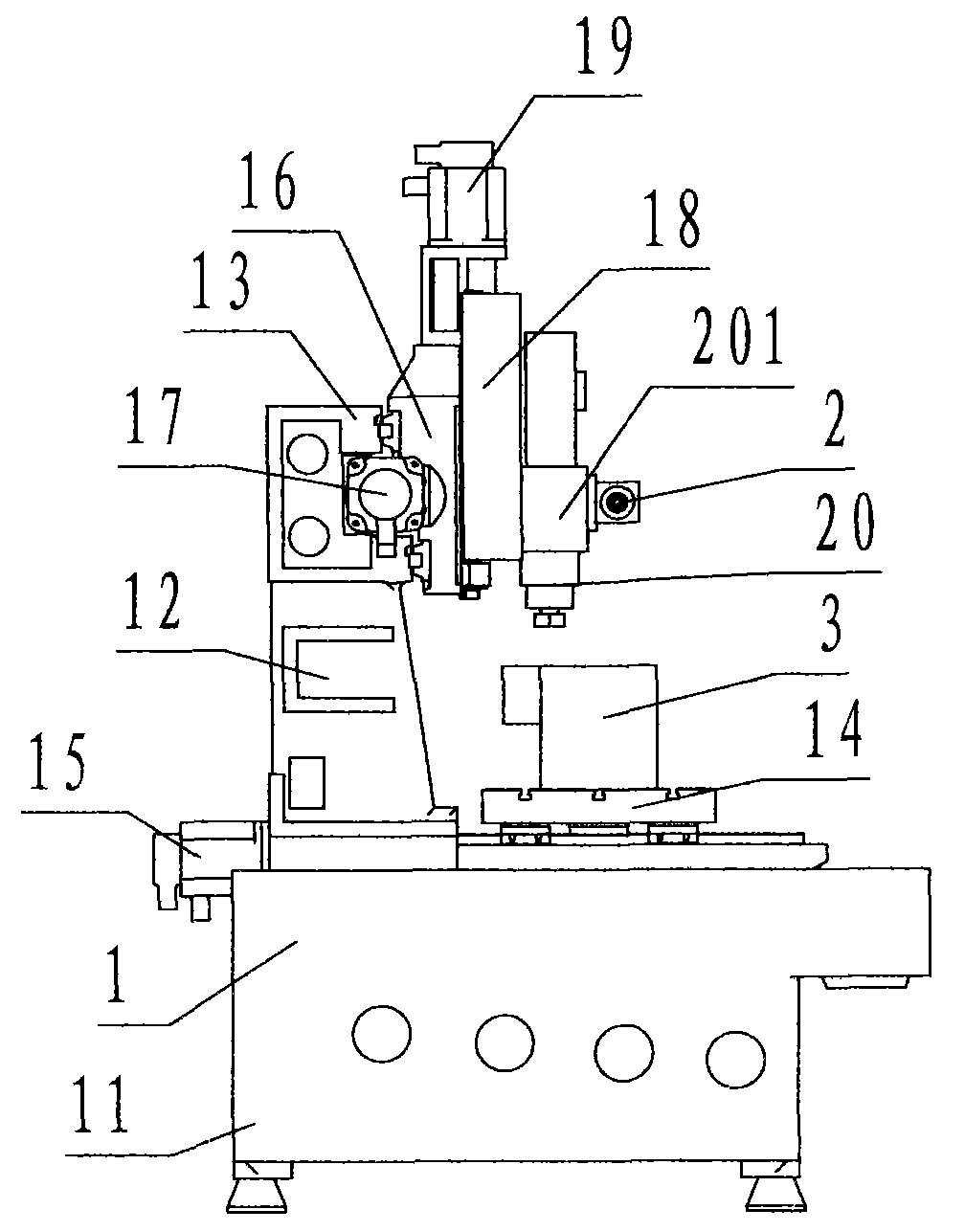

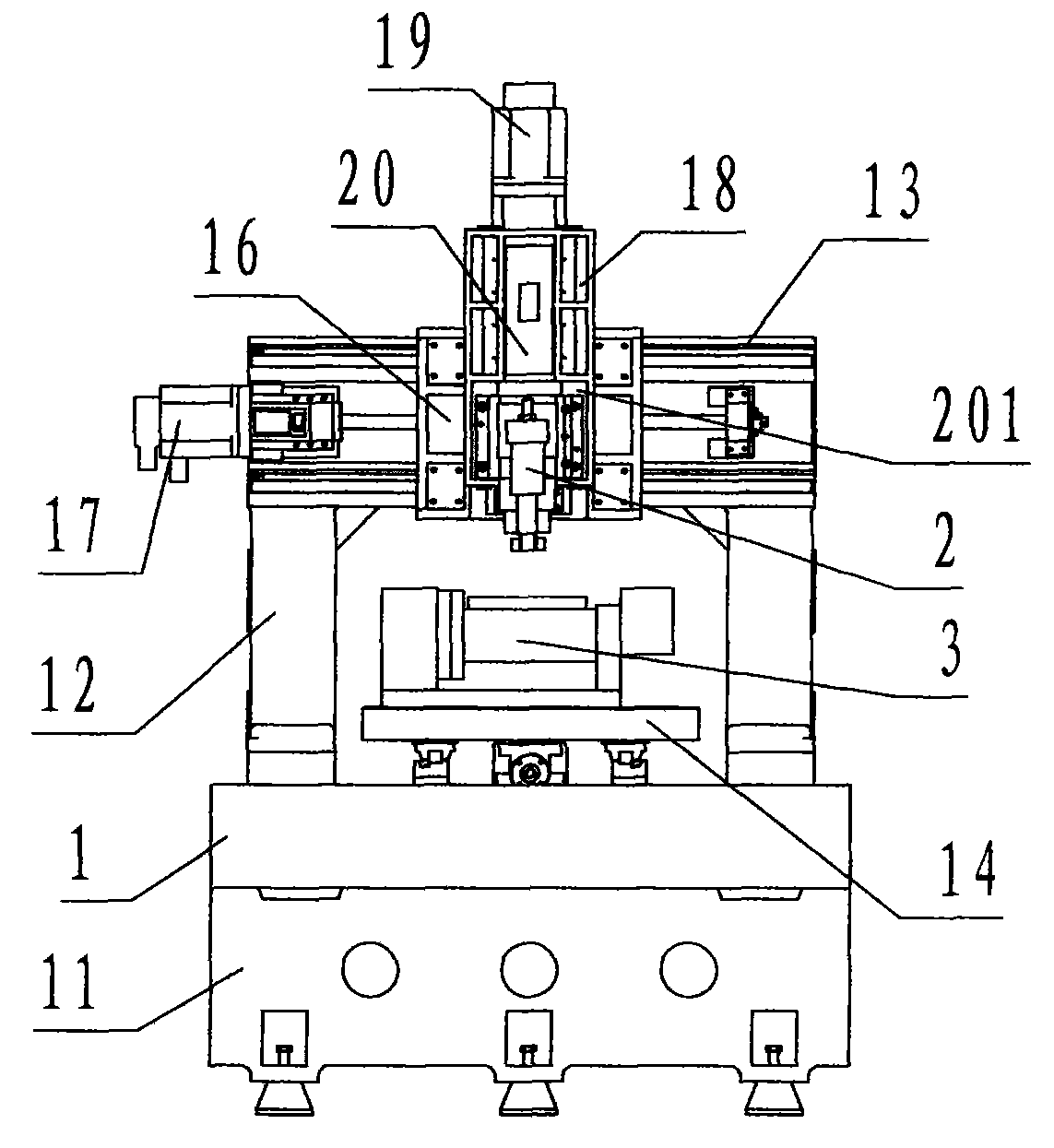

[0018] Refer to Figure 1 ~ Figure 4 , The CNC jade carving, milling and polishing machine tool of the present invention includes a CNC carving and milling machine 1, a polishing machine 2, a CNC linkage turntable 3, wherein: the CNC carving and milling machine 1 is composed of a bed 11, a column 12, and a beam 13. Y-axis worktable 14, Y-axis motor 15, X-axis slide plate 16, X-axis motor 17, Z-axis slide plate 18, Z-axis motor 19, and electric spindle 20 constitute a three-dimensional rectangular coordinate system to seek movement gantry-shaped table Mobile CNC engraving and milling machine; wherein, the right side of the Z-axis slide plate 18 is fixedly provided with a spindle seat 201, the spindle seat 201 is a rectangular cylindrical steel member with a central through hole in the vertical direction, the spindle seat The right side of the 201 is provided with a rotating shaft protruding to the right orthogonally called the mill shaft; the electric spindle 20 is connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com