Container underframe for loading liquid vessel and container

A container and underframe technology, which is applied in the field of improvement of the container underframe structure, can solve the problems of easy spillage outside the box and failure to collect, etc., achieves the effects of convenient loading and unloading, ensuring support strength, and improving deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

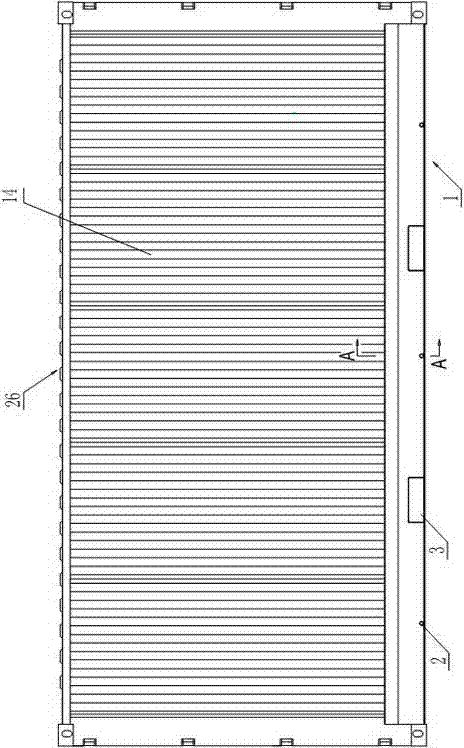

[0036] figure 1 Among them is a kind of container container 26 for holding liquid, comprising its underframe 1, side plate 14, top plate and two band door end frames, a pair of fork channel steel 3 is arranged on the underframe 1.

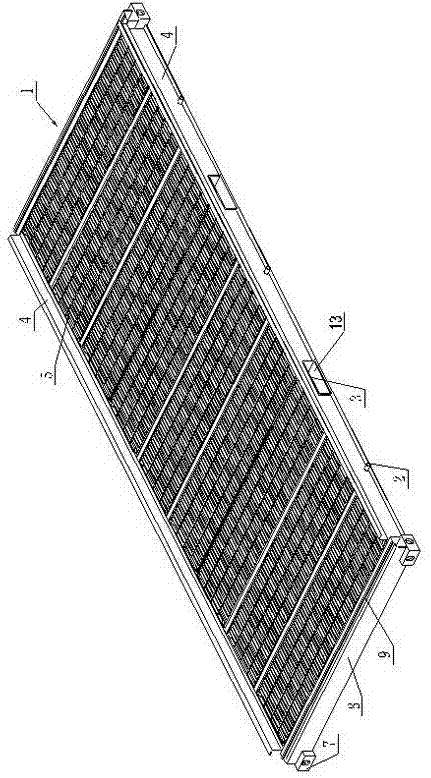

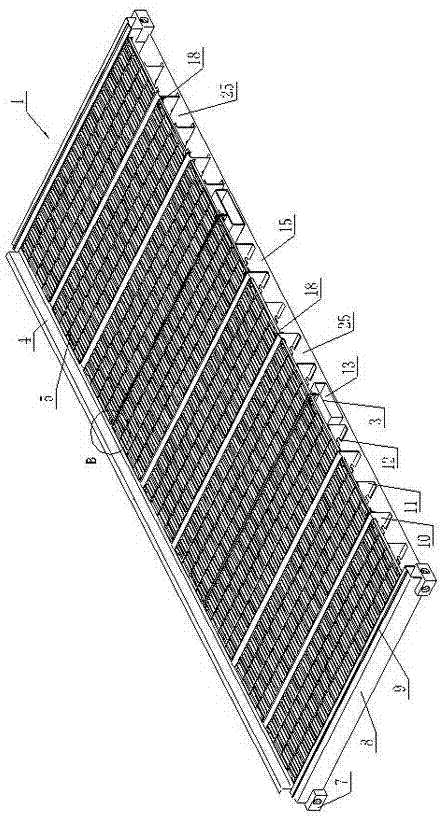

[0037] see figure 2 and image 3 , the container underframe 1 for loading liquid containers, including container bottom corner fittings 7, two bottom side beams 4, end sills 8 at both ends, a plurality of wide bottom beams 10, narrow bottom beams 11, fork groove upper bottom beams 19 and supports Angle steel 18 is placed horizontally between the two bottom side beams 4, multiple grid floors 5 installed on the bottom beam, a pair of fork grooves composed of fork channel steel 3 and fork channel plate 13, and the lower floor below the bottom beam 15.

[0038] The main design concept of the present invention is that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com