Pipeline clamping tool

A technology for clamping tools and pipes, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unfavorable pipe installation efficiency, increase work content, increase cost, etc., to improve pipe installation efficiency, easy production and manufacturing, and structure reasonably simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and their descriptions.

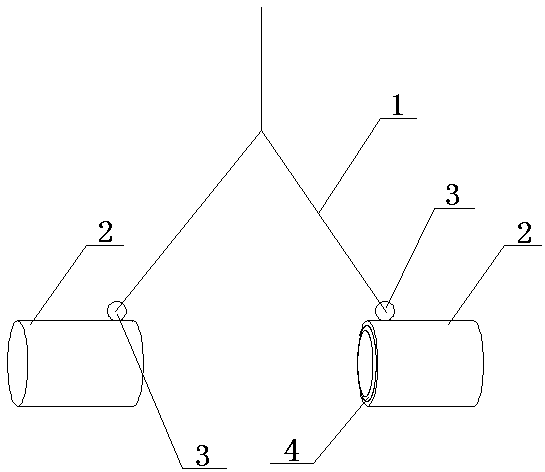

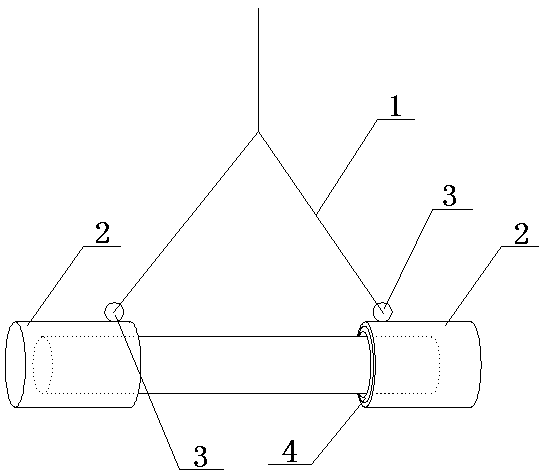

[0012] A pipe clamping tool includes a hanging rope 1 and a hanging bucket 2 , a hanging ring 3 is arranged on the outer wall of the opening of the hanging bucket 2 , and the hanging rope 1 is wound on the hanging ring 3 . A buffer layer 4 is provided in the bucket 2 . In the present invention, there are two hanging ropes 1 and two hanging buckets 2, and the outer wall at the opening of the hanging bucket 2 and the hanging ring 3 are connected by welding or screwing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com