Wireless remote control steel coil tipper

A wireless remote control, turning machine technology, applied in the direction of hoisting device, lifting device, etc., can solve the problems of frequent movement of inconvenient equipment, endanger the personal safety of operators, damage to hoisting equipment, etc., so as to facilitate frequent movement and avoid safety accidents. , the effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

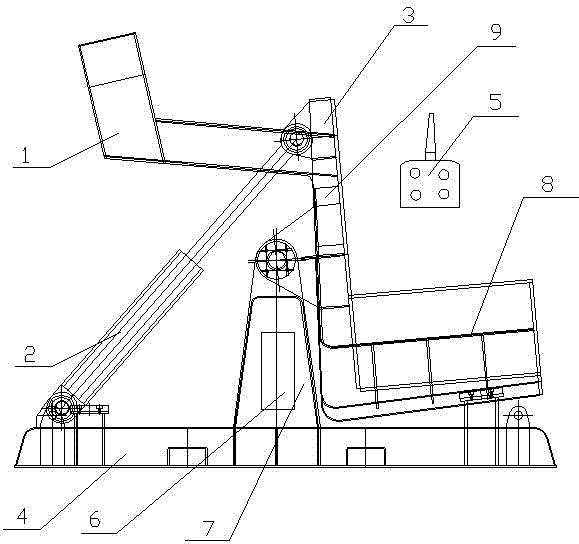

[0014] Such as figure 1 , 2 As shown, the present invention includes a counterweight 1, a turning cylinder 2, a turning mechanism 3, a base 4, a remote control transmitting device 5, and a control mechanism 6 with a remote control receiving device.

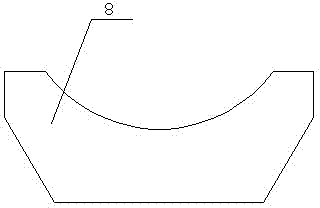

[0015] The base 4 is arranged horizontally. A support 7 is provided at the center of the base 4. The turning mechanism 3 includes a first turning member 8 for placing steel coils. The first turning member 8 is placed on the base 4 on the side of the support 7. The end of the turning member 8 close to the support 7 is connected with a second turning member 9. The first turning member 8 and the second turning member 9 are in an L-shaped arrangement with each other in an integral structure. The middle of the back of the second turning member 9 is rotatable Is connected to the upper end of the support 7; the other side of the support 7 is provided with a counterweight 1, which is connected to the opposite end of the second flipping member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com