Continuous melting furnace

A continuous melting furnace and furnace body technology, applied in the field of continuous melting furnaces with large-sized crucibles, can solve the problems such as failure to meet production requirements, poor material temperature uniformity, and output decline, so as to improve production efficiency and product quality, extend service life, The effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

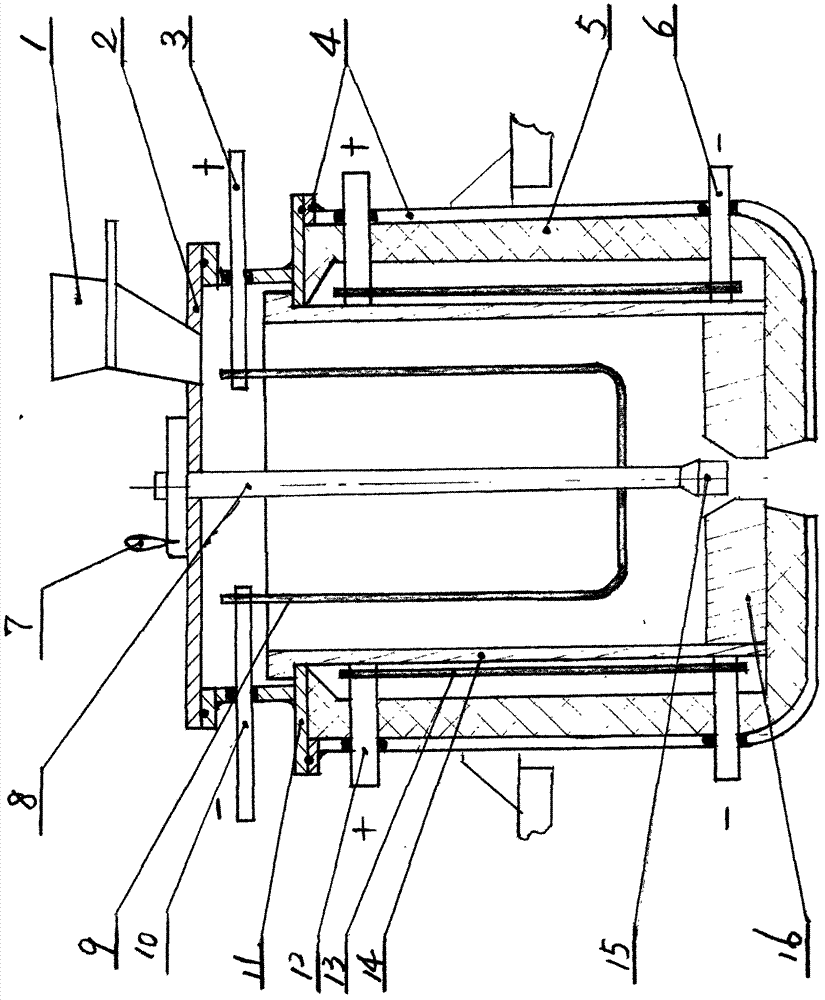

[0007] With reference to the accompanying drawings, it comprises a body of furnace 4, a large furnace cover 11 is arranged above the body of furnace, a refractory insulation material 5 is installed in the body of furnace 4, a crucible 14 is contained in the body of furnace with the refractory insulation material 5, and a discharge table 16 Installed at the bottom of the crucible 14, there is a discharge port on the discharge table, there is a main heater resistance rod 13 between the outer side of the crucible and the refractory insulation material, the main heater positive electrode 12 and the main heater negative electrode 6 are installed on the furnace body 4, the two ends of the resistance rod of the main heater are respectively connected with the positive electrode 12 of the main heater and the negative electrode 6 of the main heater. There is a small furnace cover 2 on the top of the crucible, and there is a feeding hopper 1 on the small furnace cover. The upper end is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com