Method for producing dichloroethane by comprehensively utilizing refined dry gas

A technology of dichloroethane and refining dry gas, applied in gas fuel, organic chemistry, petroleum industry, etc., can solve problems such as side reactions, deactivation, resource waste, etc., to ensure complete reaction, prevent local overheating, stay time uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

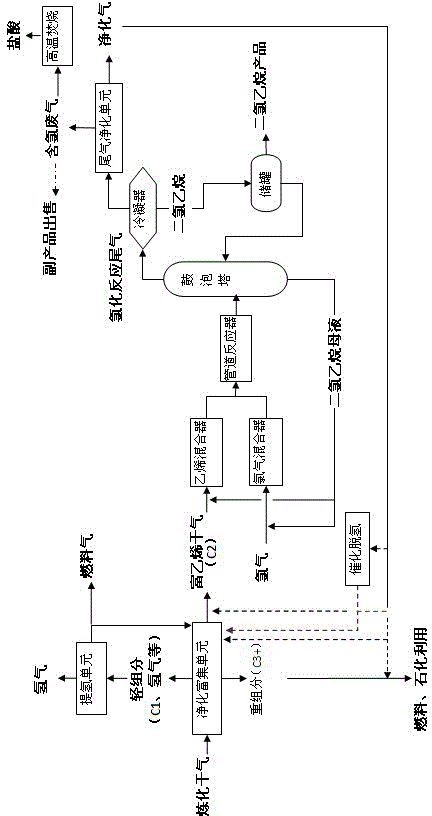

[0042] refer to figure 1 : In the flow process of the present invention, purification and enrichment unit, hydrogen extraction unit, reaction unit, and tail gas purification unit are included, wherein the reaction unit is composed of ethylene mixer, chlorine mixer, pipeline reactor, bubble column, condenser, storage tank ; In the tail gas purification unit, a catalytic dehydrogenation device can also be added as needed.

[0043] This embodiment includes the following steps:

[0044] (1) Composition of a refinery dry gas:

[0045] composition H 2 O 2 N 2 CO 2 CH 4 C 2 h 6 C 2 h 4 C3+ h 2 S C 2 h 2 Wt% 1.67 0.52 20.05 3.7 34.18 27.48 6.47 5.8 1000ppm 200ppm

[0046] The refinery dry gas is separated by membrane separation, desulfurization, decarbonization, and dealkyne combined device to obtain a product with a C3+ content of 80%, which is used as a chemical raw material for export; light components mainly composed ...

Embodiment 2

[0057] This embodiment includes the following steps:

[0058] (1) Composition of a refinery dry gas:

[0059] composition H 2 O 2 N 2 CO CH 4 C 2 h 6 C 2 h 4 C3+ H2S h 2 o Wt% 1.76 0.27 29.15 1.6 25.5 12.78 23.14 11.63 1000ppm 2000ppm

[0060] The refinery dry gas is first purified and enriched by the intercooler oil absorption process to obtain a product with a C3+ content of 95%, which is returned to the refinery for recycling; The desulfurization and dehydration unit is separated to obtain light-component mixed gas mainly composed of C1 and hydrogen, and ethylene-rich dry gas with ethylene content of 69%, ethane content of 26%, methane content of 5%, moisture content of 5 ppm, and hydrogen sulfide content of 3 ppm.

[0061] (2) The C1 and hydrogen-based light-component mixed gas obtained from the pressure swing adsorption device in step (1) enters the pressure swing adsorption hydrogen extraction device to extract h...

Embodiment 3

[0072] This embodiment includes the following steps:

[0073] (1) Composition of a refinery dry gas:

[0074] composition H 2 O 2 N 2 CO 2 CH 4 C 2 h 6 C 2 h 4 C3+ h 2 S Wt% 2.2 0.98 16.76 1.2 25.6 14.56 38.36 0.34 3ppm

[0075] The refined dry gas is separated by a combined process of deoxidation, dehydration, pressure swing adsorption and temperature swing adsorption to obtain ethylene-rich dry gas with an ethylene content of 75%, an ethane content of 14%, and a methane content of 10%. The obtained light components are sent to the hydrogen extraction unit.

[0076] (2) The light components from step (1) are separated by membrane to obtain hydrogen with a purity of 99.5%, which is used in petrochemical hydrogenation units; the analytical waste gas mainly composed of C1 enters the fuel gas pipeline network and is used as fuel gas.

[0077](3) The ethylene-rich dry gas from step (1) and the chlorine gas from outside the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com