Data-filtering-based method for judging blast furnace hanging

A data and blast furnace technology, applied in the field of blast furnace suspension material judgment based on data filtering, can solve the problems of inconvenient modification of the rule base, complex structure, fuzzy conclusions, etc., to reduce fluctuations in furnace conditions and energy consumption, improve production efficiency, and ensure stability Anterograde effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

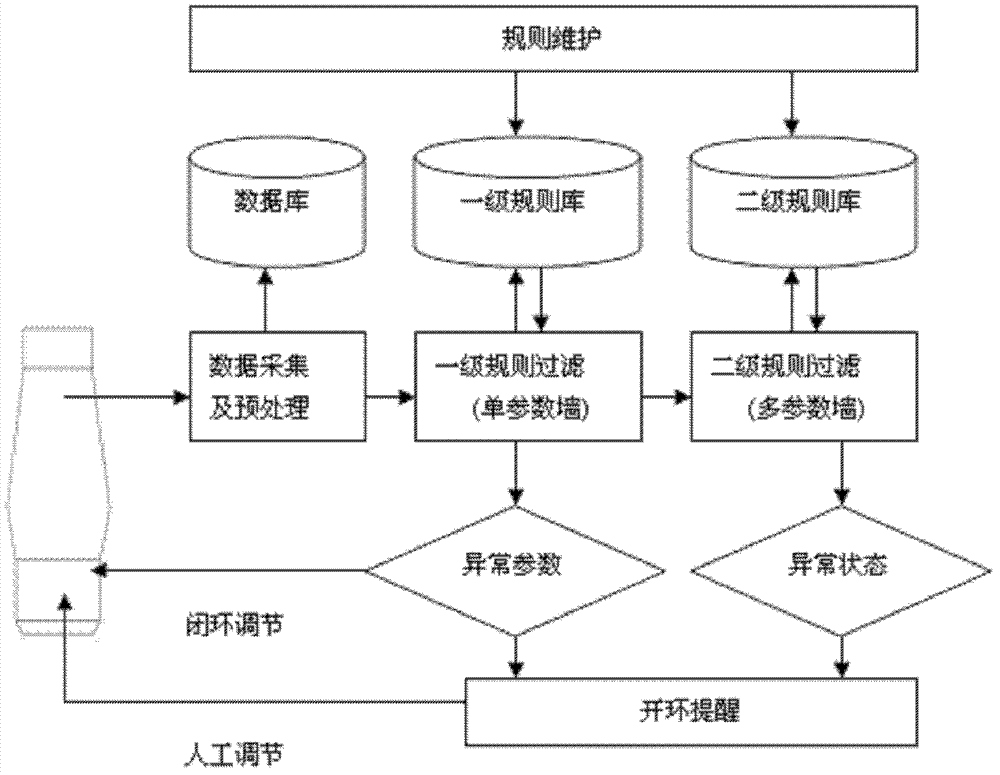

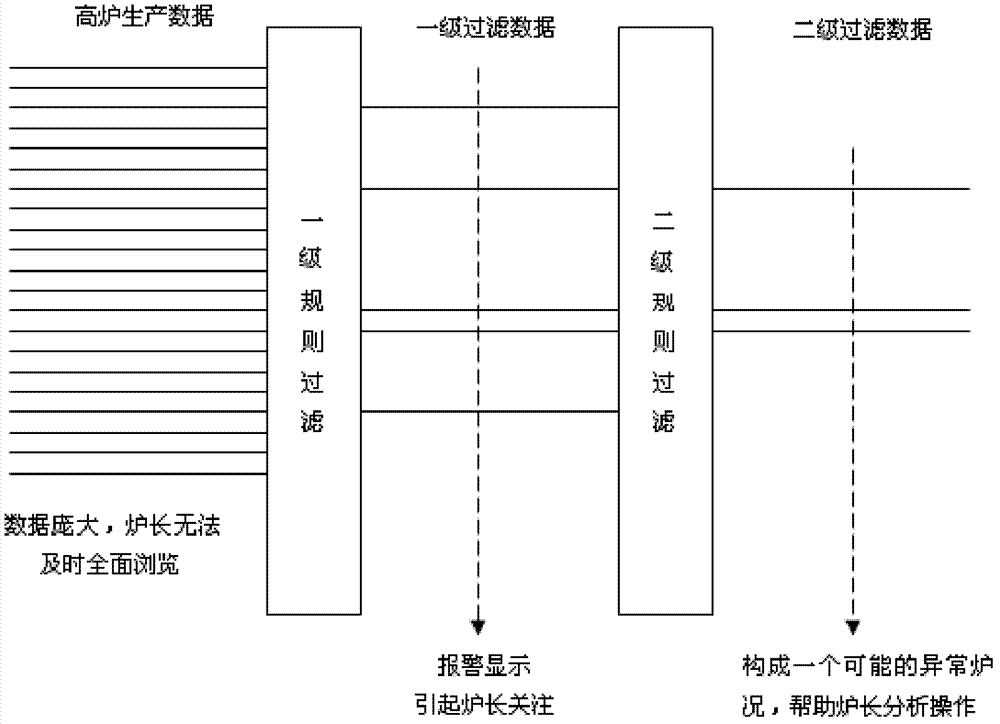

[0027] Such as figure 1 As shown, the present invention provides a method for judging blast furnace material suspension based on data filtering. The system adopted includes establishing a data collection and processing module, a first-level rule base module, a second-level rule base module, a result output module and a rule maintenance module.

[0028] 1. Data acquisition and processing module

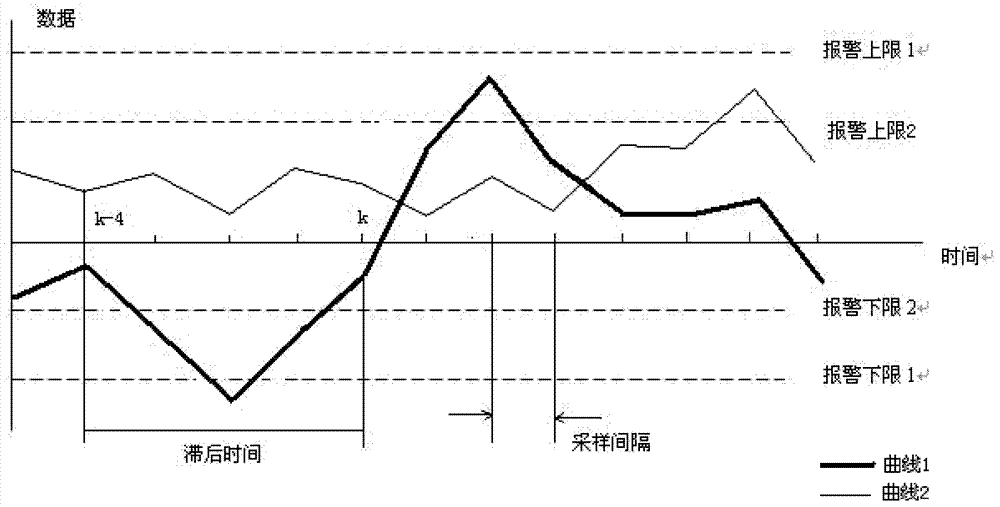

[0029] The original data is provided by the on-site secondary computer, which is a set of fixed-period data sequences. According to the sampling interval provided by the first-level rule base, the field data is stored at the minimum sampling interval. In order not to miss the maximum and minimum values within the sampling interval, and to filter out the data that has no effect on the antegrade motion of the blast furnace, only the mean (as basic data), maximum and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com