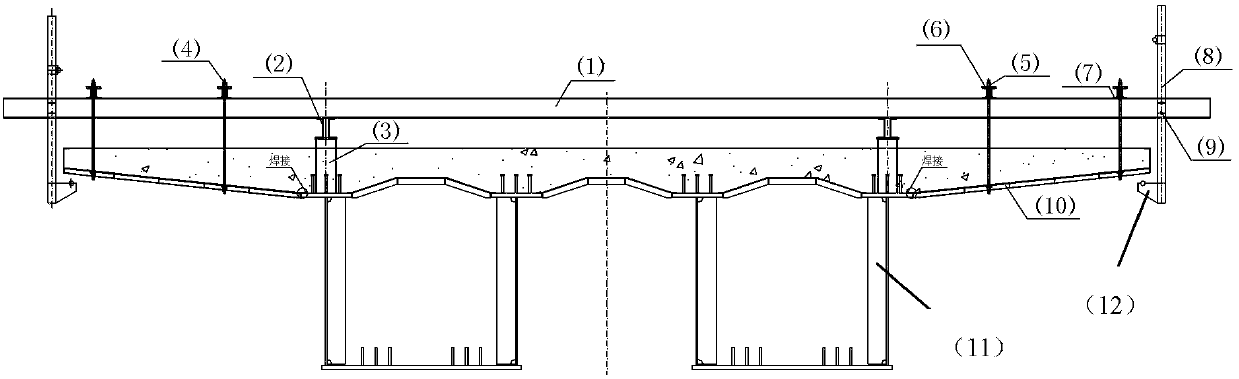

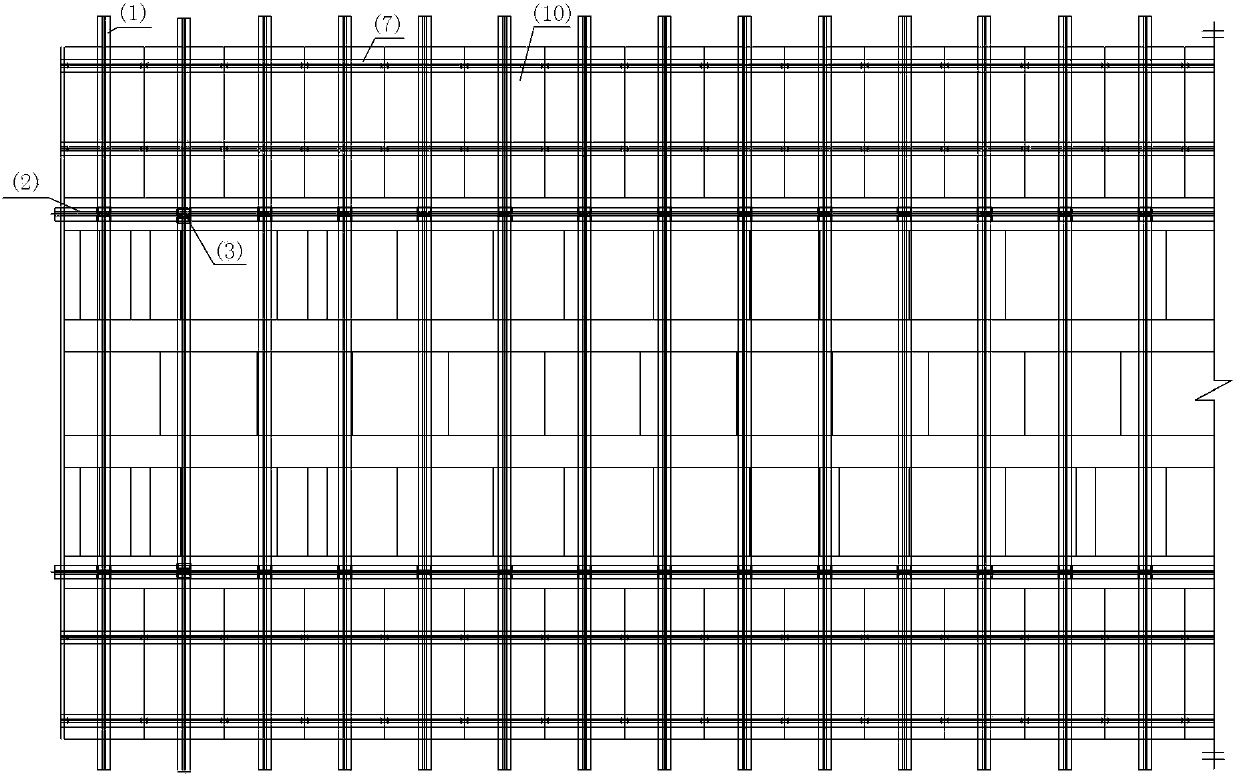

Steel and concrete combined box girder concrete wing plate formwork and construction method

A technology of steel-concrete combination and construction method, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult installation of wing plate formwork, difficult to ensure construction safety, and large impact on road traffic, so as to shorten the construction period and reduce processing time. The effect of low difficulty and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The steel-concrete combined box girder concrete wing plate template and construction method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Now take a certain project as an example: the project is located above the Fifth Ring Road in Beijing, in the middle of the Meishikou Highway Bridge, and uses a 36m steel-concrete combined box girder. Due to the construction of the box girder spanning the Fifth Ring Road, the construction process is affected by the traffic on the Fifth Ring Road, and the construction of the concrete wing plate is very difficult. During construction, it is considered that the bottom formwork of the wing plate should be in the form of non-demolition steel formwork, so as to reduce the span of five rings. Difficulty of ring road construction. The length of the flanges on both sides of the steel box girder is 2.358m, so the length of the concrete flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com