Cam follower

A technology of cam follower and sliding cam, which is applied in the direction of engine components, transmissions, machines/engines, etc., can solve the problems of huge purchase and manufacturing costs, and achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

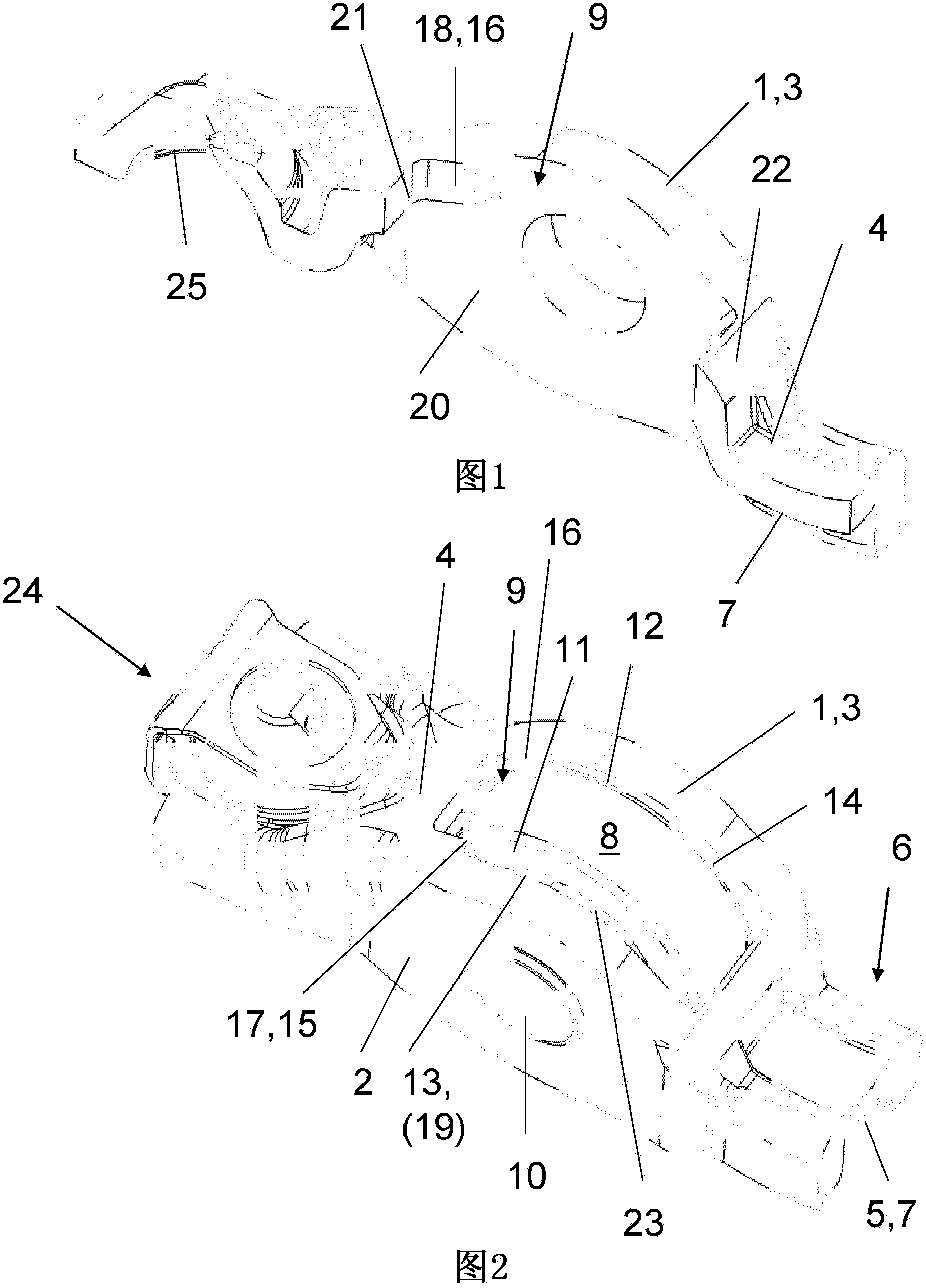

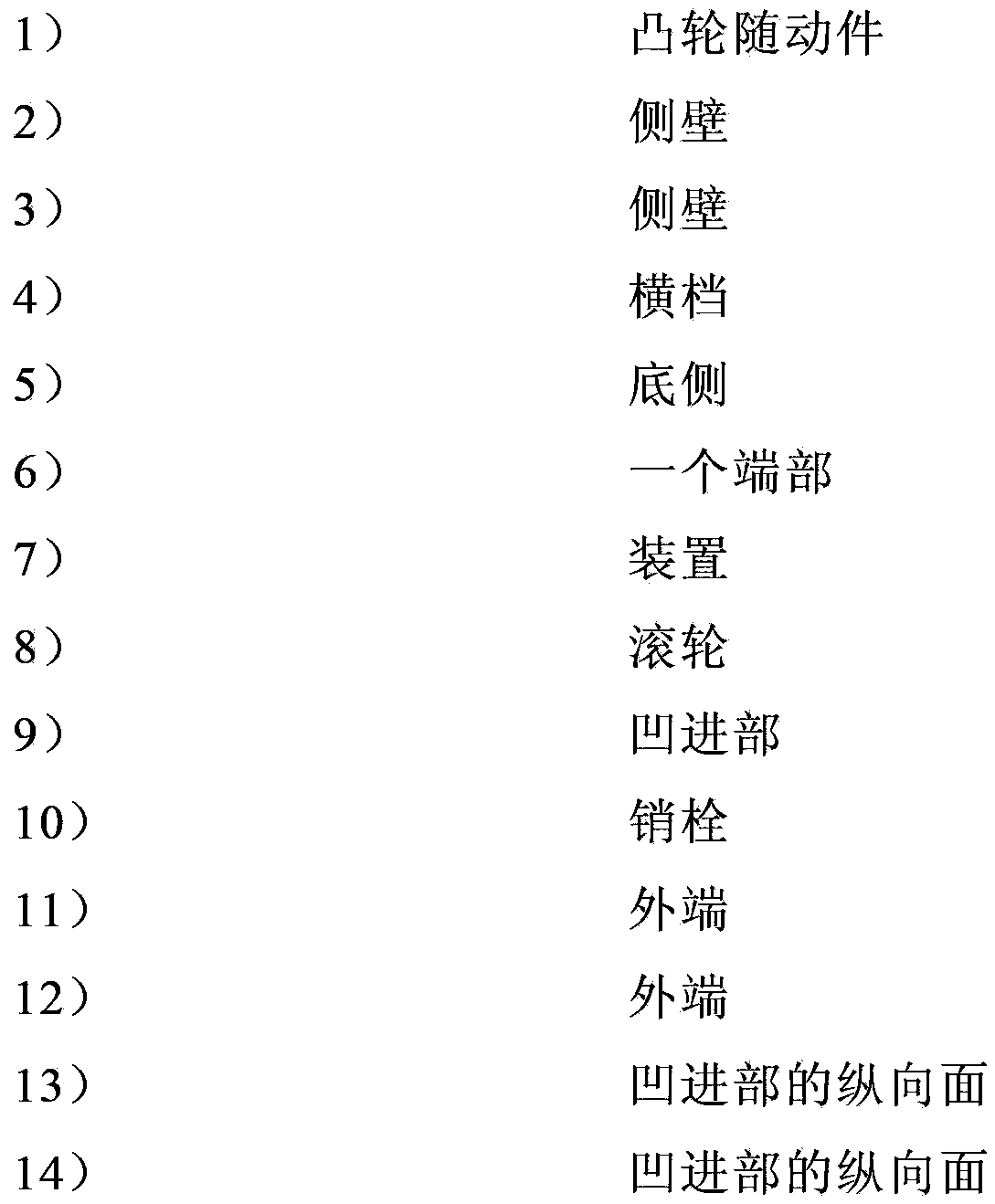

[0017] A cam follower 1 is shown as a sheet metal drawbar for a valve drive of an internal combustion engine. The cam follower has two substantially vertical side walls 2 , 3 which are connected by an upper crosspiece 4 such that an inverted U-shaped profile is formed in cross section.

[0018] On the underside 5 of the crosspiece 4 a device 7 for a ventilation valve is applied at one end 6 . On the other end 24 of the crosspiece 4 , on the underside 5 , a spherical segment-shaped contact surface 25 for the support element is shown.

[0019] The crosspiece 4 has a rectangular frame-like recess 9 penetrated by a roller 8 . The roller 8 is used for camming and in this case runs on a pin 10 placed in the side walls 2 , 3 via a bearing 23 . as by figure 2 As can be seen, a needle bearing arrangement is provided as bearing means 23 which extends with a slight axial play directly in front of the inner surfaces 19 , 20 of the side walls 2 , 3 . It can also be seen that the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com