Control device of belt type continuously variable transmission

一种无级变速器、控制装置的技术,应用在传动装置、传动装置控制、带有齿的元件等方向,能够解决油压增加、油压降低、带夹持力降低等问题,达到防止滑动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

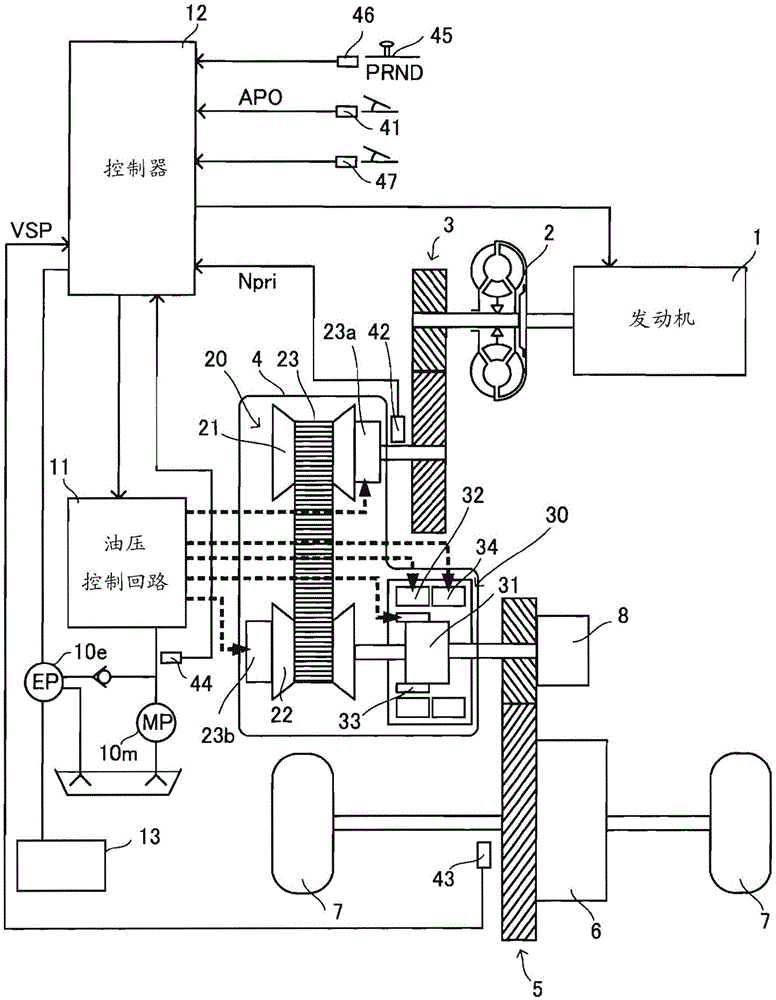

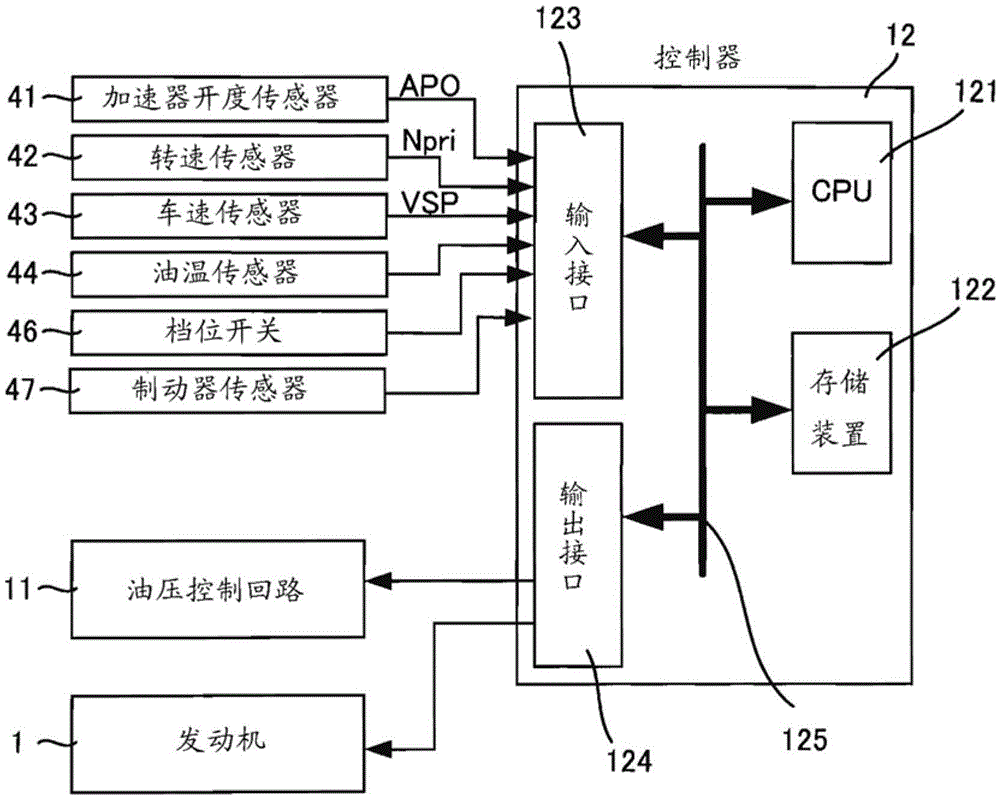

[0040] figure 1 It is a schematic configuration diagram of a vehicle on which the continuously variable transmission according to the first embodiment of the present invention is mounted. The vehicle includes an engine 1 as a power source. The output rotation of the engine 1 is transmitted to the drive wheels 7 via a torque converter 2 with a lock-up clutch, a first gear set 3 , a continuously variable transmission (hereinafter simply referred to as “transmission 4 ”), a second gear set 5 , and a final reduction device 6 . transfer. The second gear set 5 is provided with a parking mechanism 8 that mechanically locks the output shaft of the transmission 4 so that it cannot rotate when the vehicle is parked.

[0041] In addition, the vehicle is provided with a mechanical oil pump 10 m that inputs the rotation of the engine 1 and is driven by a part of the power of the engine 1 , and an electric oil pump 10 e that is driven by receiving electric power supply from the battery 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com