External anti-tipping valve

A dump valve, external technology, applied in the field of mechanical valves, can solve problems such as accidental leakage and accidental closing of the anti-dump valve, and achieve the effect of increasing the degree of freedom and reducing the risk of accidental fuel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

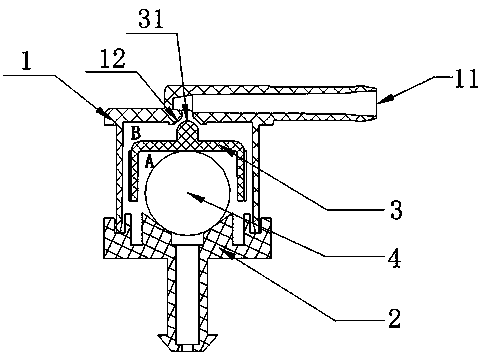

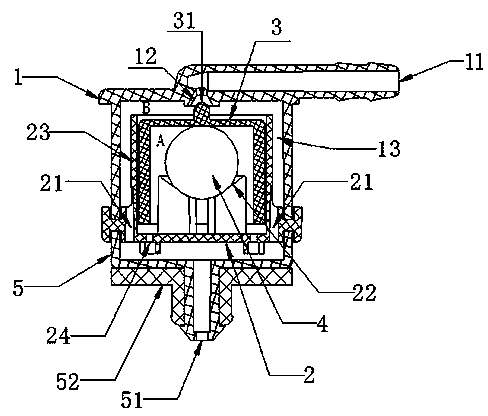

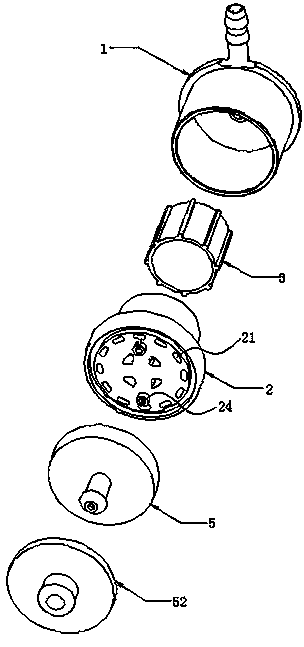

[0023] combine figure 2 As shown, a 90-degree external anti-dumping valve of the present invention, the valve body 1 and the valve seat 2 are connected to form a valve cavity B, and the top of the valve body 1 is integrally provided with a first vent 11, and the first vent 11 is connected with the valve The cavity B is connected through the valve port 12, and the center of the bottom of the valve seat 2 is provided with a conical pit 22, and a cross groove can be provided in the longitudinal direction of the conical pit 22;

[0024] A cover-shaped float 3 is arranged above the valve seat 2, and a valve core 31 that cooperates with the valve port 12 and can close the first vent port is provided on the top outside of the float 3. The valve core 31 and the valve port 12 can be in contact with a spherical surface. It can also be contacted with a rounded surface, and the line contact can ensure the tightness of the valve closing. The conical structure can ensure that it can be eff...

Embodiment 2

[0030] combine Figure 4 As shown, a 180-degree external anti-dumping valve of the present invention, on the basis of the structure of Embodiment 1, retains the internal isolation cylinder 23 and the external valve cover 5', and the third vent 51' and The included angle between the first ventilation ports 11 is adjusted to 180 degrees, and a curved cavity is formed between the valve cover 5', the valve seat 2 and the third ventilation port 51', and the second ventilation port 21 and the liquid discharge port 24 are in the The cavity between the valve cover 5' and the valve seat 2 communicates with each other, where the gas flow and liquid gather. This 180-degree external anti-dumping valve does not need to use a rubber sealing ring to be embedded with the fuel tank, and only needs to use a separate pipeline to connect the third vent 51' to the fuel tank.

Embodiment 3

[0032] combine Figure 5 As shown, a 0-degree external anti-dumping valve of the present invention, on the basis of the structure of Embodiment 1, retains the internal isolation cylinder 23 and the external valve cover 5'', and the third vent 51' ' and the angle between the first vent 11 is adjusted to 0 degrees, then a curved cavity is formed between the valve cover 5'', the valve seat 2 and the third vent 51'', the second vent 21 and the third vent 51'' The liquid discharge port 24 communicates in the cavity between the valve cover 5 ″ and the valve seat 2 , where the gas flow and liquid are collected. This 0-degree external anti-dumping valve does not need to use the rubber sealing ring to be embedded with the fuel tank, and only needs to use a separate pipeline to connect the third vent 51'' to the fuel tank.

[0033] The 180-degree external anti-dump valve described in Embodiment 2 and the 0-degree external anti-dump valve described in Embodiment 3 are mainly used on mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com