Correction device for wire harness of locomotive connector

A proofreading device and connector technology, which is applied to measuring devices, instruments, measuring electronics, etc., can solve problems such as low efficiency and high failure rate, and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

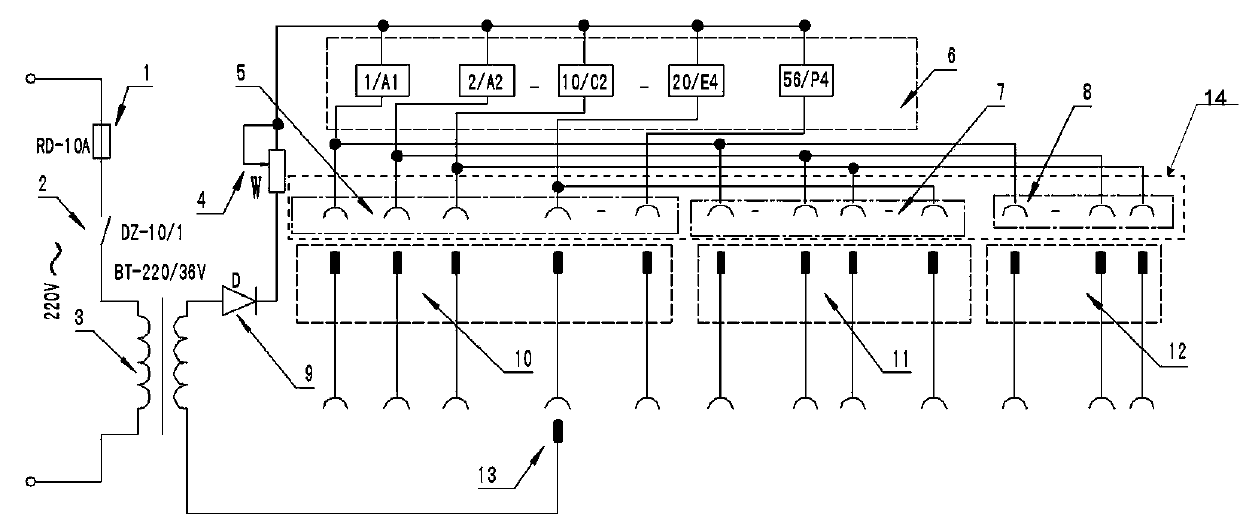

[0024] Working principle: Pass 220V, 50HZ AC power through the machine tool transformer, the transformer model is BT-220V / 36V, the transformer converts 220V, 50HZ AC power into 36V AC power, and the AC power passes through the rectifier diode, and the rectifier diode model 2PD5E is half-wave rectified to obtain the output DC The voltage is 36*0.45=16.2V. The DC voltage is then adjusted by the potentiometer W, and the potentiometer of the model WXD3 is adjusted to output a DC voltage of 15V, which is used as a power supply for the display screen. In the figure, the fuse model is RD-10A and the air switch model is DZ47-15 / 1 for protection.

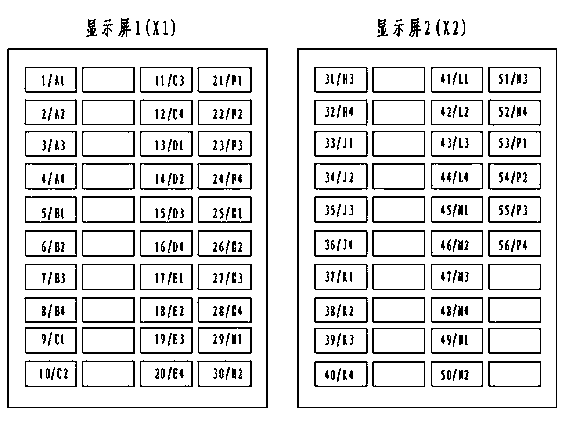

[0025] Display principle: SS3A type locomotive display screen is used as the display device, and a one-to-one correspondence relationship is established with 56-pin, 20-pin, and 10-pin socket / plug points. There are 4*10=40 display units on each display screen of SS3A. In this device, the maximum display quantity displayed is 56 cores and 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com