Optical lens linear motion zoom optical system

A technology of linear motion and optical lens, applied in the field of optical lens linear motion zoom optical system, optical lens zoom system, can solve the problems of large equipment volume, high manufacturing cost, low zoom precision, etc., to eliminate large backlash and improve precision and work efficiency, meeting the requirements of precision tracking and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

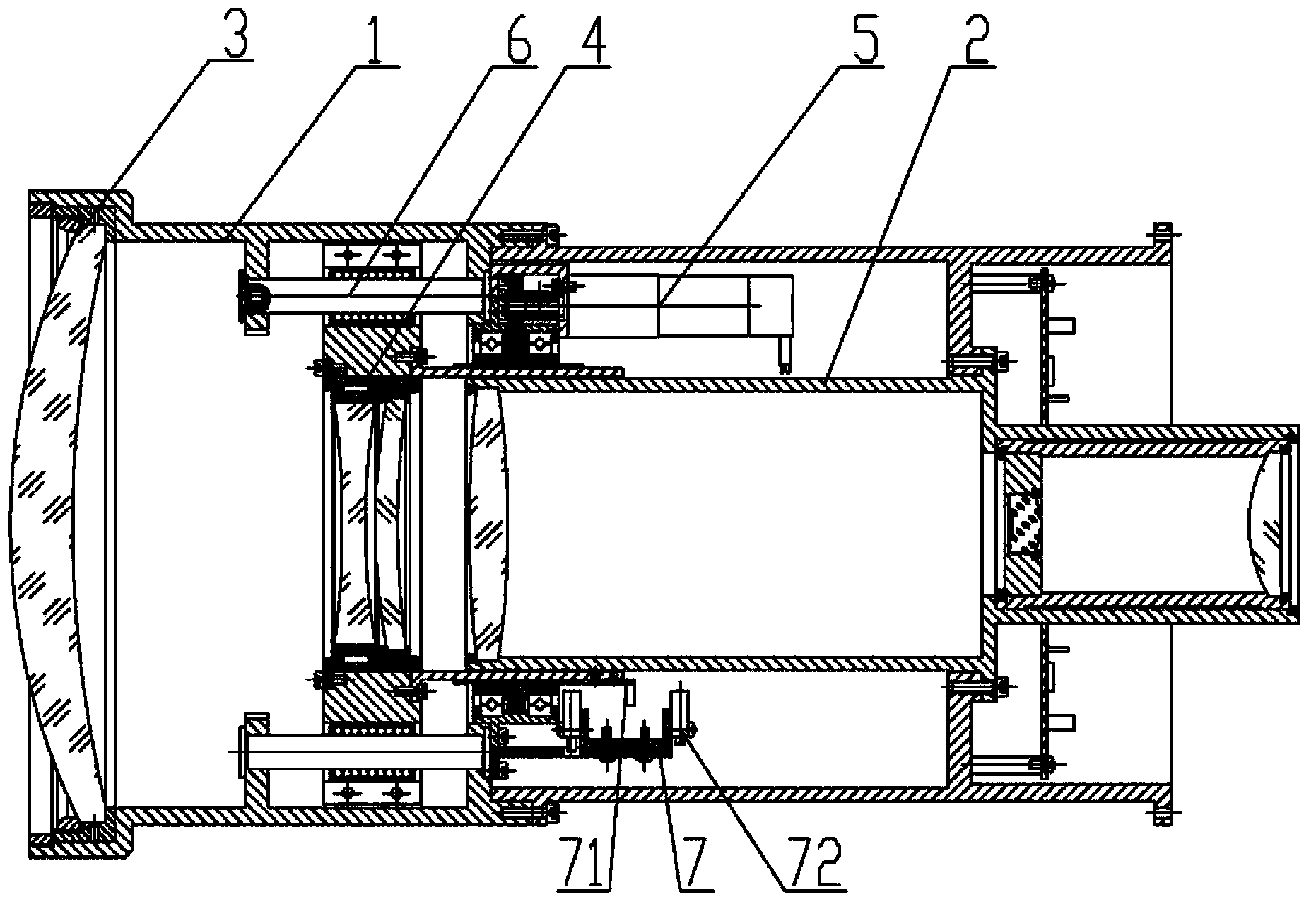

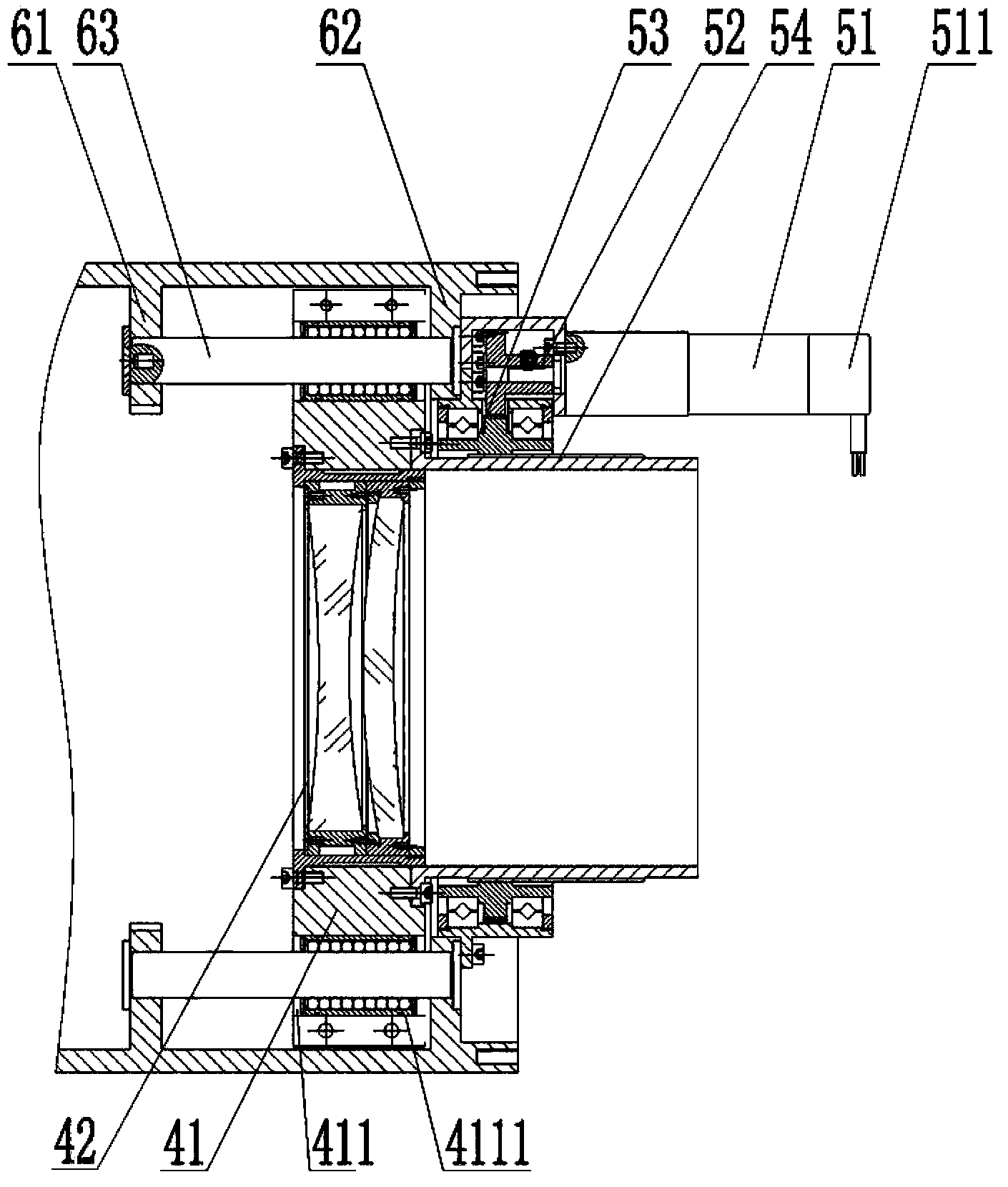

[0025] The present invention provides an optical lens linear motion zoom optical system, see attached figure 1 , a fixed frame 1 with a cavity inside, a first lens group 2 and a second lens group 3 respectively fixed at both ends of the fixed frame 1, and a zoom lens assembly 4 arranged between the first lens group 2 and the second lens group 3 , the driving device 5 for providing the zoom lens assembly 4 with reciprocating linear motion, and at least three sets of guide assemblies 6 fixedly arranged and evenly distributed on the inner surface of the fixed frame 1 for supporting and guiding the zoom lens assembly 4 .

[0026] Such as figure 2 As shown, the zoom lens assembly 4 includes a moving mirror frame 41, a zoom lens group 42 installed in the inner hole of the moving mirror frame 41; the moving mirror frame 41 is provided with a through hole 411 corresponding to the position of the guide assembly 6; the guide assembly 6 passes through the moving The through hole 411 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com