Full-automatic double-layer rotary type equipment for installing iron pieces in plastic concealed junction box

A fully automatic, glue-dark box technology, applied in the assembly/disassembly of contacts, electrical components, electrical switches, etc., can solve the problems of high labor intensity of operators, low efficiency of manual operation, and poor installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

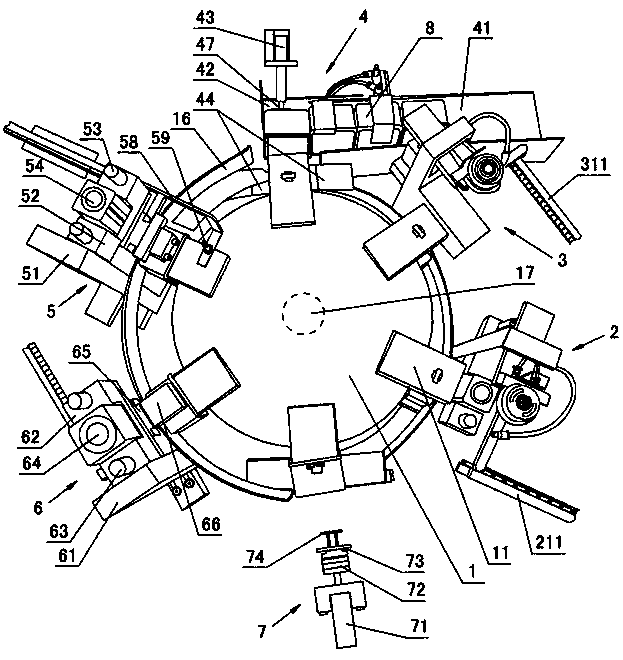

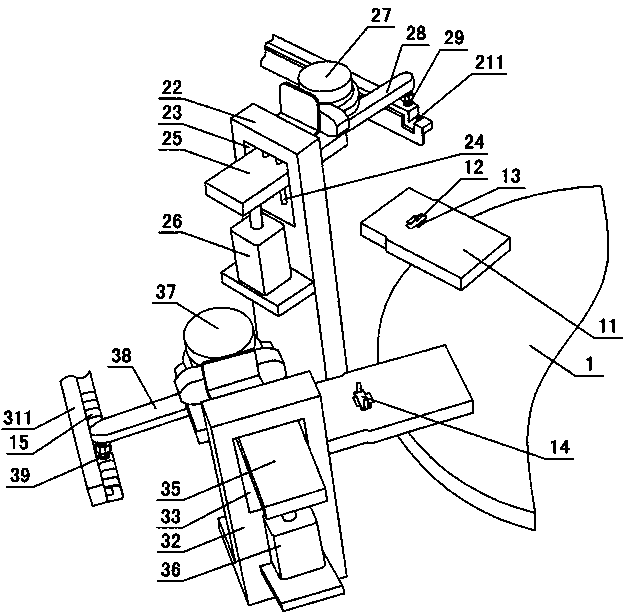

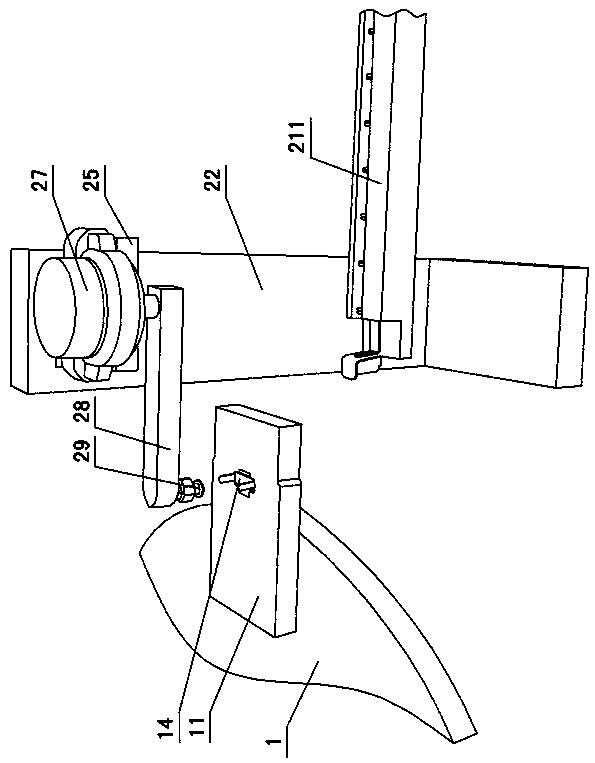

[0022] The present invention relates to a kind of fully automatic double-layer rotating type equipment for installing the iron parts of the rubber dark box, such as figure 1 — Figure 15As shown, it is characterized in that it includes a machine base, a main shaft 17 installed on the main base 10, the main shaft is driven by a power 18, an upper turntable 1 and a lower turntable 19 are installed on the main shaft, and 6 groups of molds 11 are respectively installed on the upper and lower turntables, The mold is provided with a long iron piece installation groove 12 and a short iron piece installation groove 13, and a long iron piece 14 and a short iron piece 15 are arranged in the long iron piece installation groove and the short iron piece installation groove, around the upper and lower turntables 1, 19 On the machine base 10 of the upper and lower two layers, the upper long iron device 2, the upper short iron device 3, the feeding and unloading conveying device 4, the long i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com