Electrostatic impulse generator and direct current (DC) impulse generator

An electrostatic pulse and generator technology, applied in the direction of friction generators, etc., can solve the problems of complex structure, narrow applicability, large volume, etc., and achieve the effect of simple preparation method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

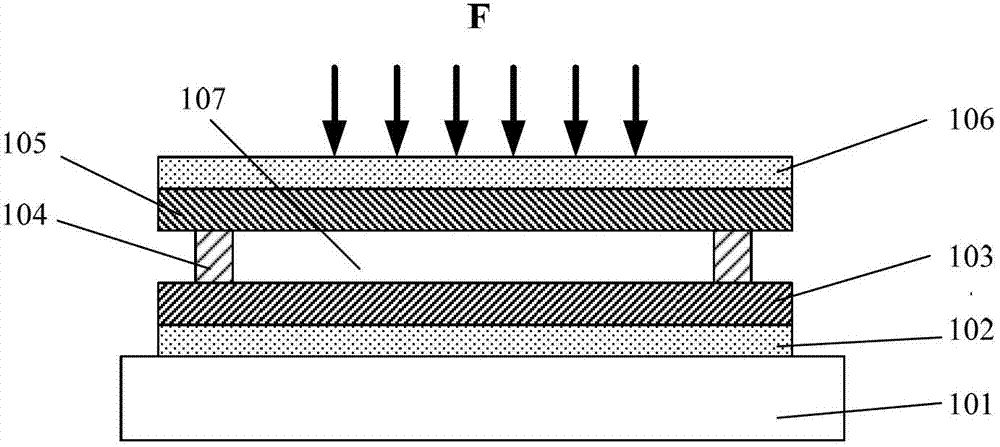

[0039] In the electrostatic pulse generator of the present embodiment, the first insulating layer and the second insulating layer all adopt thin film materials, see figure 1 , the generator is prepared on the substrate 101, the generator has a layered structure, and the generator includes a first electrode layer 102, a first insulating film layer 103, an insulating support 104, a second insulating film layer 105 and The second electrode layer 106, wherein, the material of the first insulating film layer 103 and the second insulating film layer 105 has a triboelectric sequence difference; the insulating support 104 makes the first insulating film layer 103 and the second insulating film layer 103 A gap 107 is formed between the film layers 105 , and under the action of an external force F, the first insulating film layer 103 and the second insulating film layer 105 are in contact with each other.

[0040] The materials of the first insulating film layer 103 and the second insul...

Embodiment 2

[0050] In this embodiment, the structure of the electrostatic pulse generator is the same as that in Embodiment 1, and will not be repeated here. The difference from the first embodiment is that the material surface of the first insulating film layer 103 and / or the second insulating film layer 105 facing the gap 107 in the generator is chemically modified to effectively increase the output power. For the two insulating film materials of the first insulating film layer and the second insulating film layer, more electron-losing functional groups (that is, strong electron donating groups) are introduced on the surface of the material whose polarity is positive, or on the surface of the material whose polarity is negative The introduction of functional groups that are more likely to obtain electrons (strong electron-attracting groups) can further increase the amount of charge transfer at the moment of contact, thereby increasing the contact charge density and the output power of th...

Embodiment 3

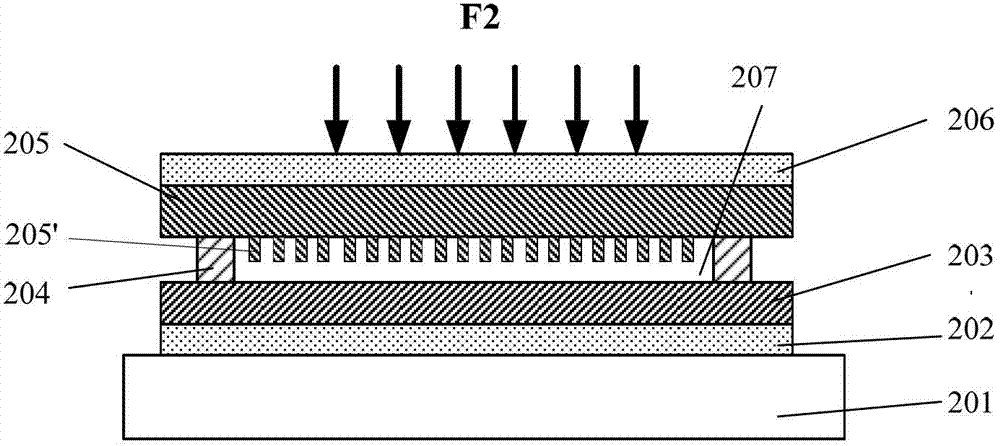

[0058] In this embodiment, the structure of the electrostatic pulse generator is the same as that in Embodiment 1, and will not be repeated here. The difference from Embodiment 1 is that one of the opposite surfaces of the first insulating film layer and the second insulating film layer is a physically modified rough surface, that is, under the action of an external force, the first insulating film layer and the second insulating film layer When the second insulating film layers are in contact, one of the surfaces in contact with each other is a physically modified rough surface.

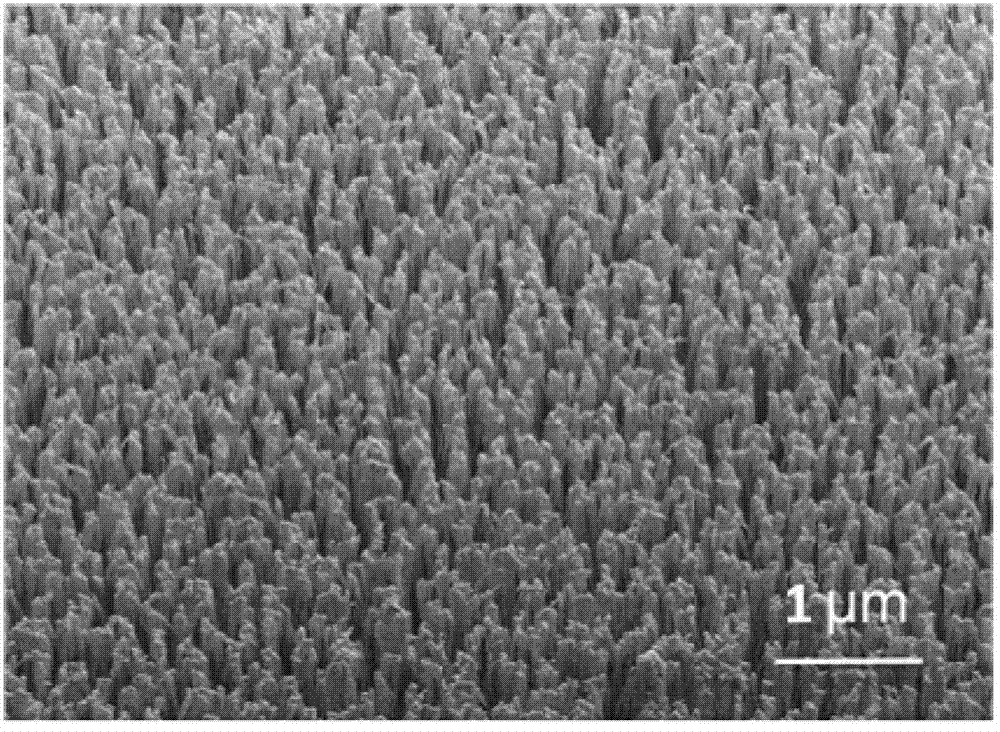

[0059] Preferably, a nanowire or nanorod array can be prepared on the surface of the first insulating film layer or the second insulating film layer facing the gap, and the nanowires or nanorods are substantially perpendicular to the first insulating film layer or the second insulating film layer. The surface of the second insulating film layer, in order to achieve the purpose of increasing the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap