Manufacturing method of wiring board and wiring board

A technology of wiring substrate and manufacturing method, applied in the directions of printed circuit manufacturing, multilayer circuit manufacturing, insulating substrate/layer processing, etc., can solve problems such as poor connection between wiring substrate and semiconductor device, and achieve the effect of reducing poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

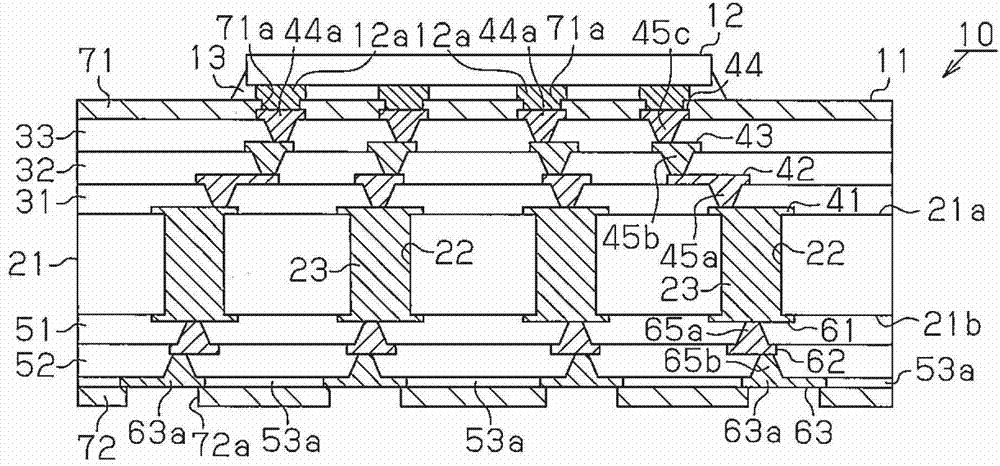

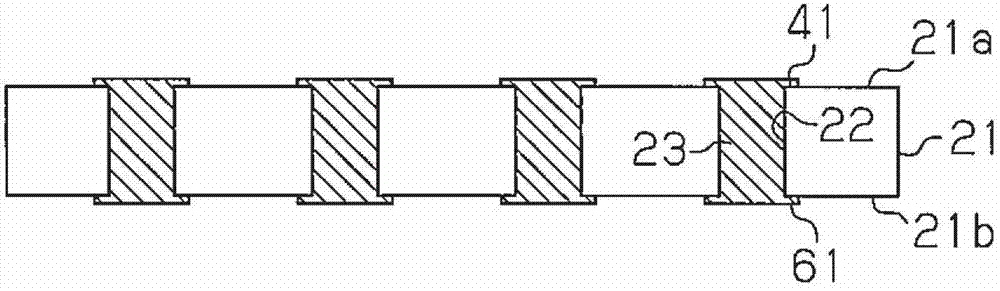

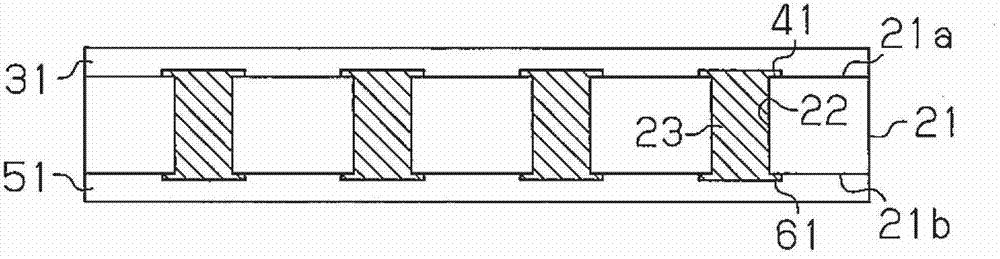

[0016] One embodiment will be described below with reference to the drawings. In addition, the drawings are for explaining a schematic structure, and do not show actual sizes and ratios.

[0017] Such as figure 1 As shown, the semiconductor device 10 (semiconductor package) includes a wiring substrate 11 and a surface mounted on the wiring substrate 11 ( figure 1 The semiconductor chip 12 on the upper surface). The wiring substrate 11 includes a core substrate 21 . For example, the core substrate 21 is a so-called glass epoxy substrate formed by curing a thermosetting insulating resin containing epoxy resin as a main component impregnated with glass fiber cloth (glass woven cloth) as a reinforcing material.

[0018] The core substrate 21 includes a first surface ( figure 1 The upper surface 21a) and the second surface on the opposite side of the first surface ( figure 1 In the lower surface 21b). A plurality of through holes 22 penetrating between the upper surface 21 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com