Glass bottle forming method

A molding method and glass bottle technology, applied in blowing-blowing glass forming machines, glass production, blowing heads, etc., can solve the problem of difficult air discharge and achieve the effect of not being prone to defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

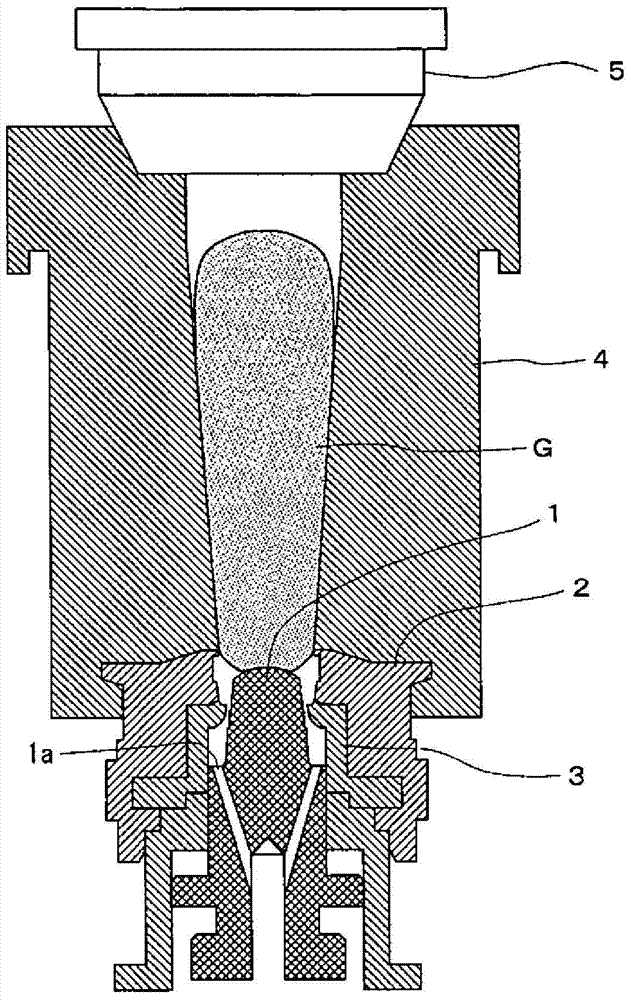

[0026] figure 1 It is a figure in which the glass material G is thrown into the preform 4 through the hopper 5 in the glass bottle molding method of this invention. The plunger 1 is inserted into the central opening of the die 2 and the guide ring 3 installed in the die, and the plunger 1 is driven in the vertical direction by a driving mechanism (not shown) such as an air cylinder. A prefabricated mold 4 is provided on the upper part of the die 2 .

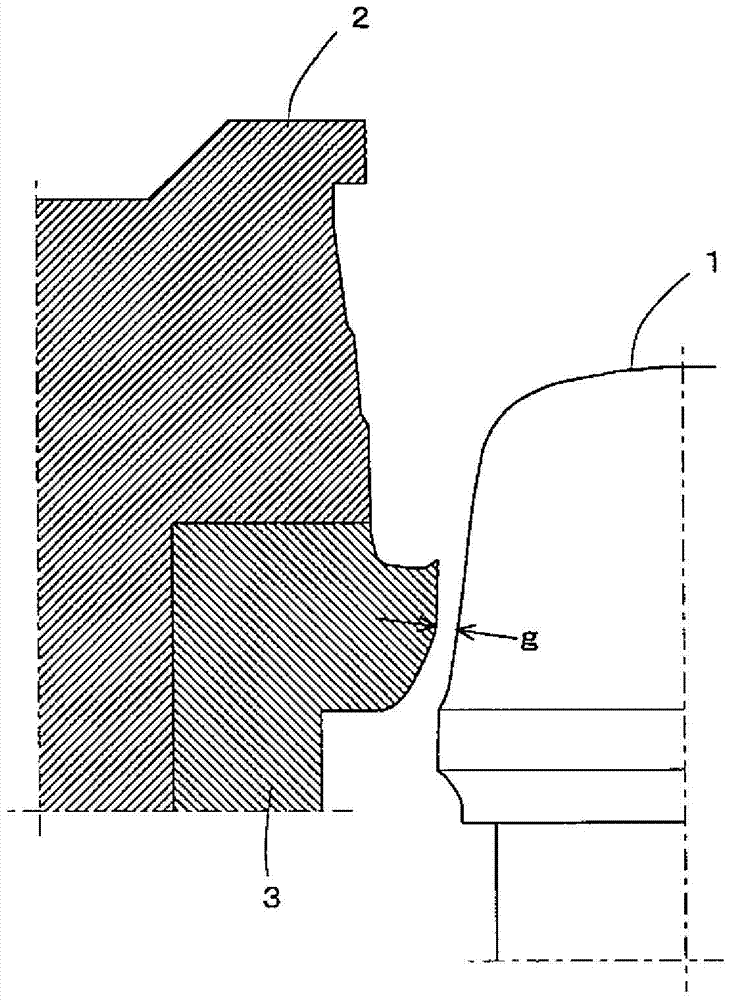

[0027] When the glass blank G is dropped into the prefabricated mold 4, the position of the plunger 1 is Figure 4 The normal position drops about 6mm figure 2 At this time, the minimum gap g between the side of the plunger 1 and the inner surface of the guide ring 3 is 0.1-1.1mm.

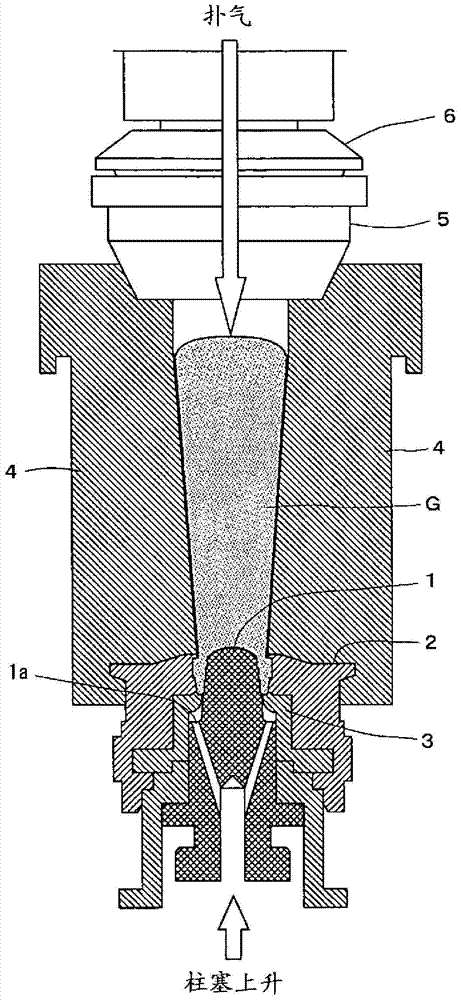

[0028] After the input of the glass blank is completed, if image 3 As shown, the baffle plate 6 descends above the funnel 5, and the compressed air is supplied from the baffle plate to the prefabricated mold 4 to blow air. Plunger 1 basically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com