Sizing agent for reinforced fiber and its application

A technology for strengthening fibers and sizing agents, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of inability to show performance, decreased adhesion, and carbon fiber breakage, and achieves less decomposition, excellent strength, and excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

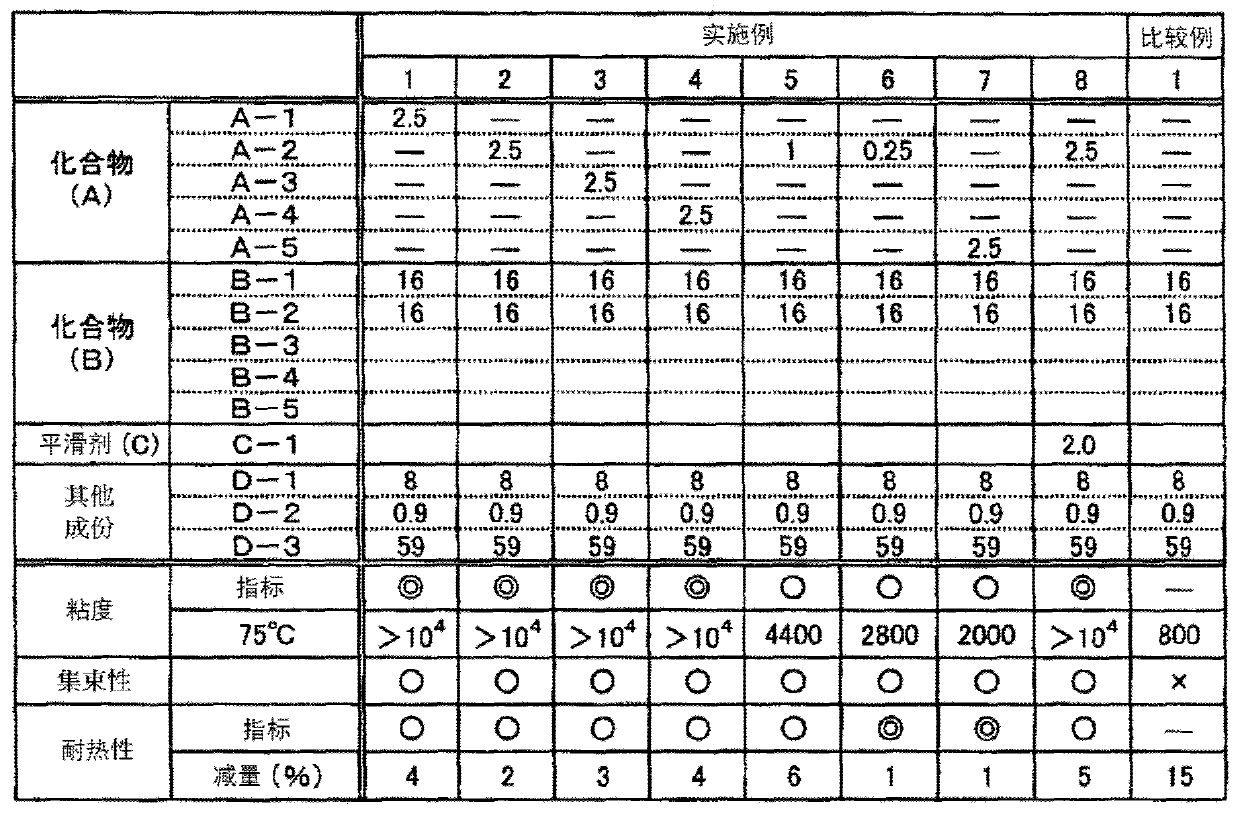

[0149] (Examples 1-11, Comparative Examples 1-4)

[0150] The following components (A-1 to D-3) were mixed at the ratios (parts by weight) described in Tables 1 to 6 to obtain sizing agents for reinforcing fibers of Examples 1 to 11 and Comparative Examples 1 to 4, respectively. . The results are shown in Tables 1-4.

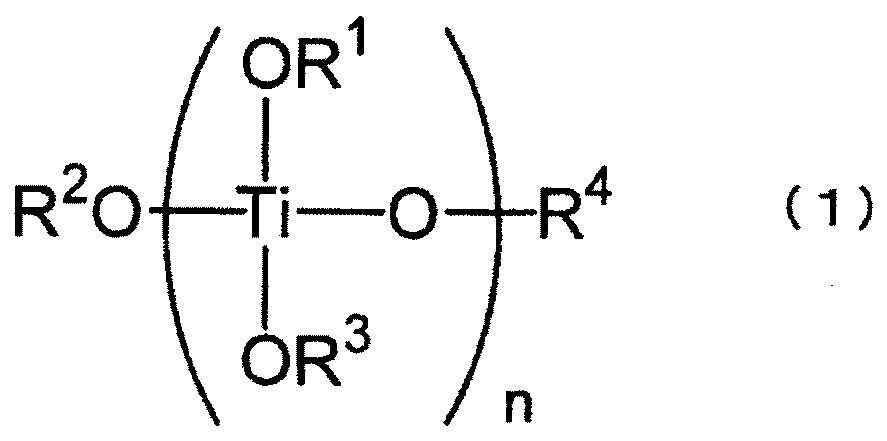

[0151] A-1 Tetraethoxytitanium

[0152] A-2 Titanium tetraisopropoxide

[0153] A-3 Tetrabutoxytitanium

[0154] A-4 Titanium Tetraisopropoxyethanoloxide

[0155] A-5 Tetrabutoxytitanium tetramer

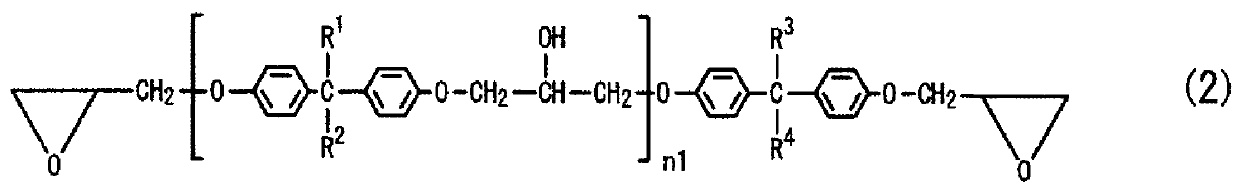

[0156] B-1 Liquid epoxy resin (JER-828 molecular weight: 380, manufactured by Mitsubishi Chemical Corporation, the molecule having a hydroxyl group is included in the ratio of 1 molecule in 10 molecules)

[0157] B-2 Solid epoxy resin (JER-1001 molecular weight: 900, manufactured by Mitsubishi Chemical Corporation)

[0158] B-3 Polyester polymerized by 2mol of PEG / maleic anhydride at both ends of Bis-A (acid value: 4.6KOHmg / g)

[0159] B-4 made by reacting PTM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com