Saw device manufacturing method

A manufacturing method and device technology, which is applied in the direction of manufacturing tools, semiconductor devices, electrical components, etc., can solve the problems of easy degradation of SAW device quality and achieve the effect of suppressing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

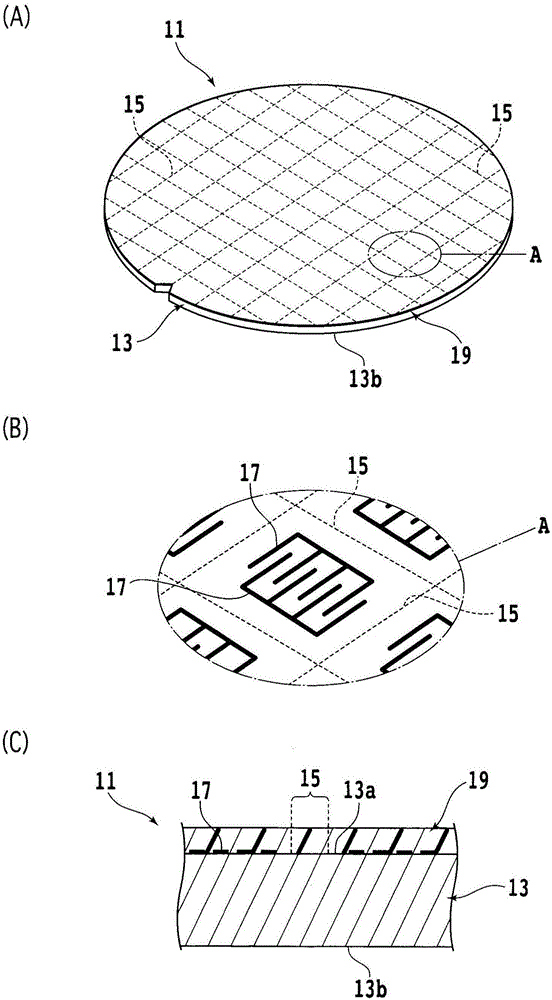

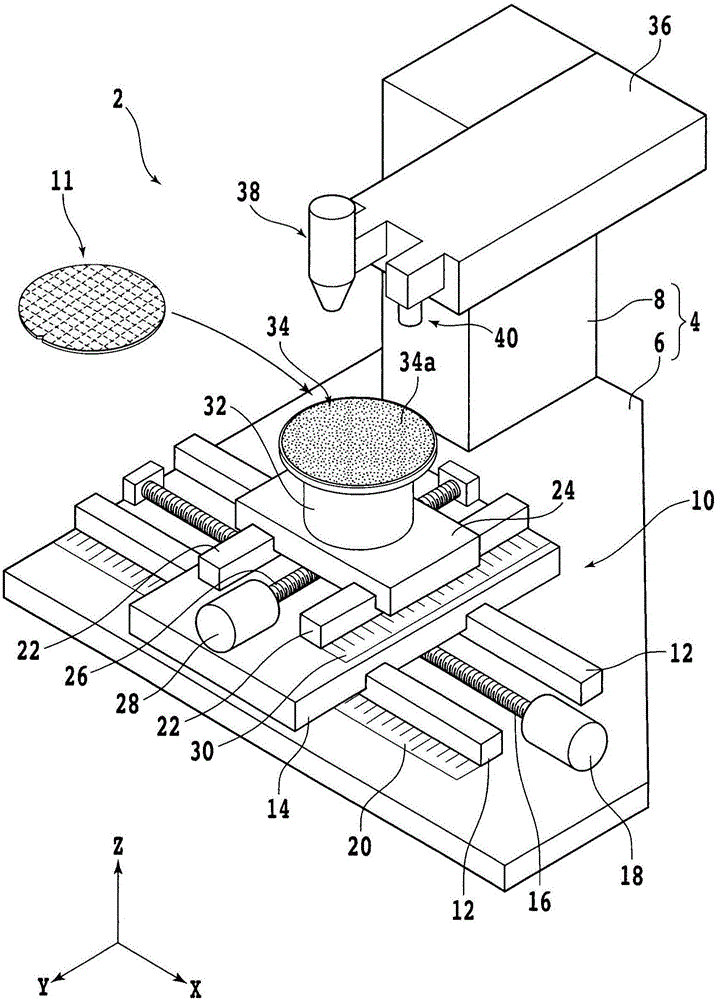

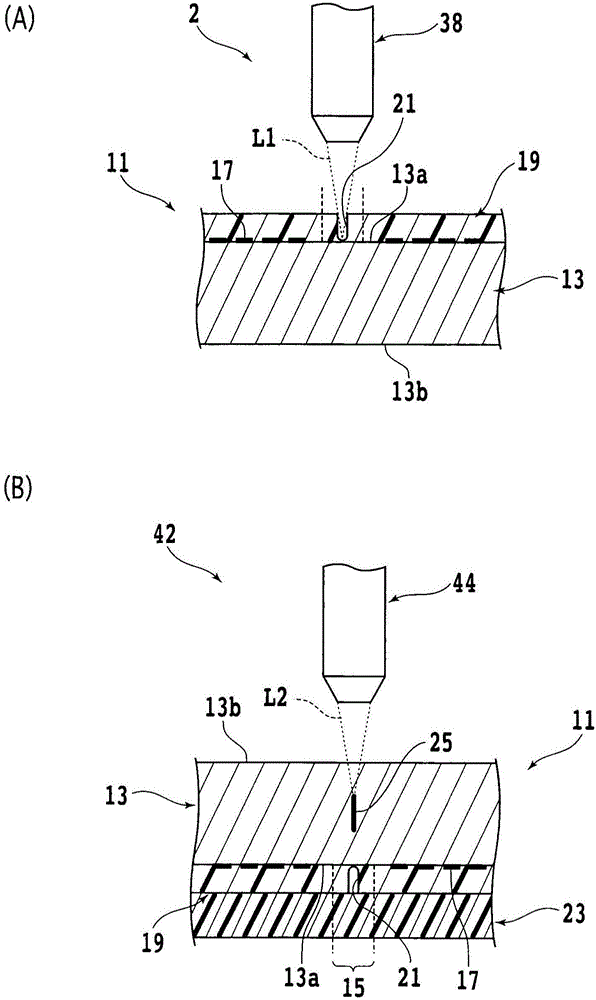

[0020] Embodiments of the present invention will be described with reference to the drawings. The manufacturing method of the SAW (Surface Acoustic Wave: Surface Acoustic Wave) device of the present embodiment includes a laser machining groove forming step (refer to image 3 (A)), modified layer formation process (refer to image 3 (B)) and the division process (refer to Figure 4 ). In the laser machining groove forming step, laser beams are irradiated to the clad layer constituting the SAW device wafer to form laser machining grooves along planned division lines (streets).

[0021] In the modified layer forming step, the crystallized substrate constituting the SAW device wafer is irradiated with laser light to form modified layers along the planned division lines. In the dividing step, an external force is applied to the SAW device wafer to divide the SAW device wafer into a plurality of SAW devices along planned dividing lines. Hereinafter, the method of manufacturing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com