Auxiliary propeller folding mechanism of model airplane glider

A technology of auxiliary propeller and folding mechanism, applied in the field of machinery, can solve the problem of no front plane dragging of a model aircraft glider, and achieve the effects of improving aerodynamic performance, reducing resistance and prolonging airborne time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

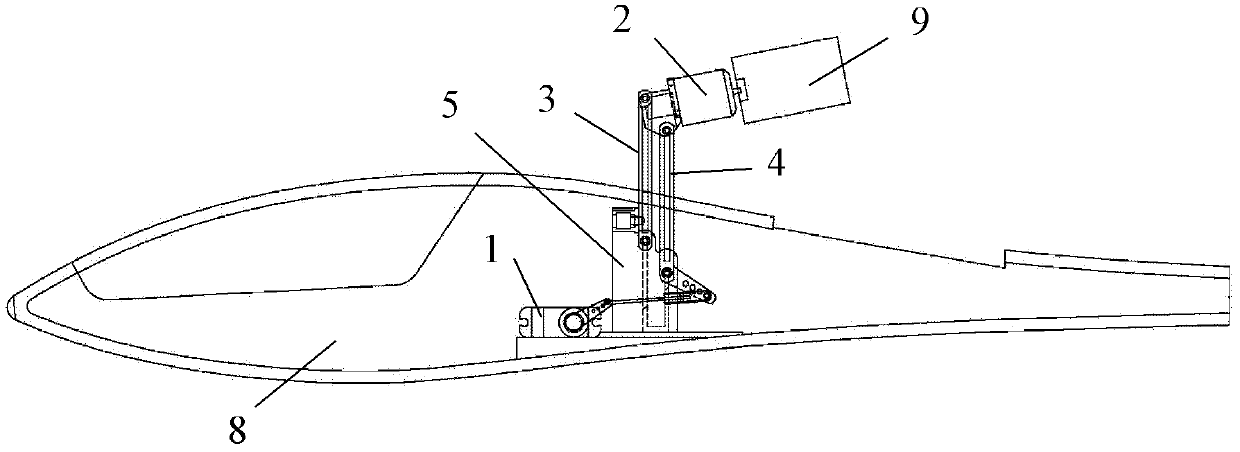

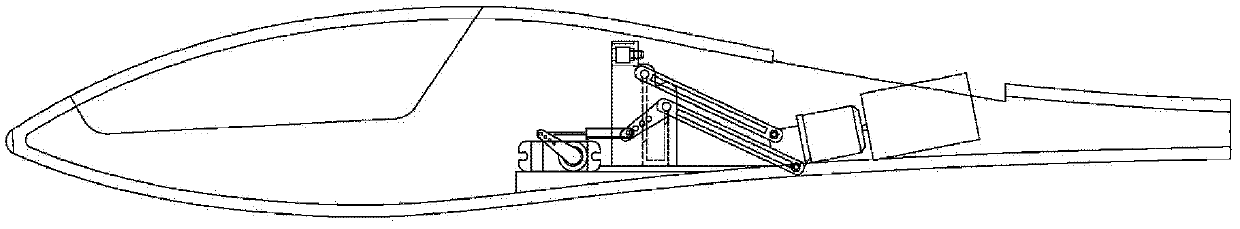

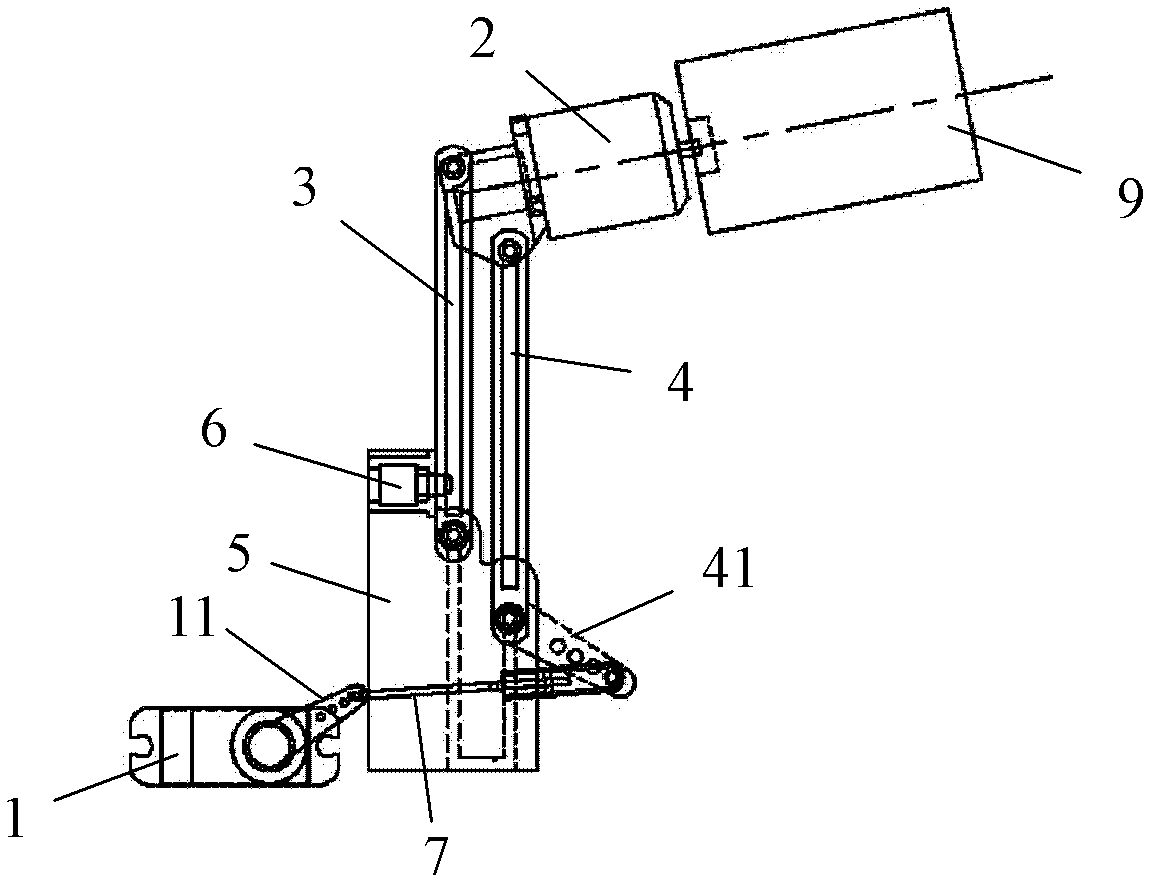

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, an auxiliary propeller folding mechanism of a model airplane glider of the present invention includes a steering gear 1 and an auxiliary propeller 9, the steering gear 1 includes a swing arm 11, and the auxiliary propeller 9 is connected to a power The output shaft of the element 2 is connected, wherein, the power element 2 is hinged with one end of a first connecting rod 3, and the power element 2 is hinged with one end of a second connecting rod 4, and the first connecting rod 3 of the The other end is hinged with a fixed piece 5, the other end of the second connecting rod 4 is also hinged with the fixed piece 5, the hinge point between the power element 2 and the first connecting rod 3 and the power element 2 and the second connection The connecting line between the hinge point of the rod 4, the connecting line between the hinge point of the power element 2 and the second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com