Solid rocket vehicle

A technology for solid rockets and aircraft, applied in aircraft, aircraft control, aircraft parts, etc., can solve problems such as inability to fly to a designated location, high flight dynamic pressure, and short controllable stay in the air, so as to solve the problems that cannot be applied to solid rocket aircraft , improve the lift-to-drag ratio and air time, and simplify the complexity of the control mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

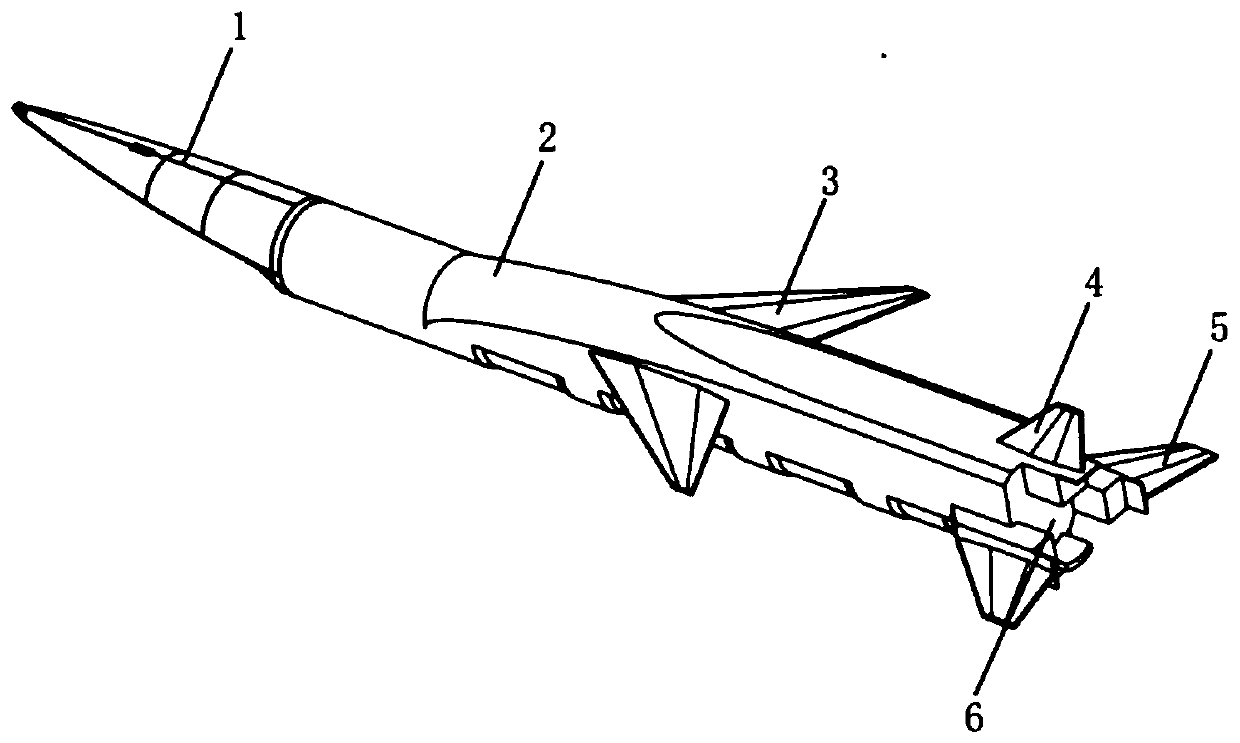

[0036] A solid rocket vehicle, comprising a head load compartment 1, a rocket body 2, a wing 3, a rudder 4, a horizontal tail rudder 5, an engine nozzle outlet 6, an adjustable gas flow baffle 7, and an inclined buffer device 8; The fastest flight speed of the solid rocket vehicle does not exceed Mach number 4, and the maximum flight altitude does not exceed 30km.

[0037] The head load compartment 1 is a lifting body shape; one end of the arrow body 2 is connected with the head load compartment 1, and the other end is connected with the engine nozzle outlet 6; the head load compartment 1 is connected with the Said rocket bodies 2 are connected to form a symmetrical structure with a plane of symmetry; said wings 3 are installed on both sides of the middle of said rocket body 2 and are symmetrical along said plane of symmetry; said rudder 4 is installed on said rocket body 2 is close to the nozzle outlet 6 of the engine and is located in the plane of symmetry; the horizontal ru...

Embodiment 2

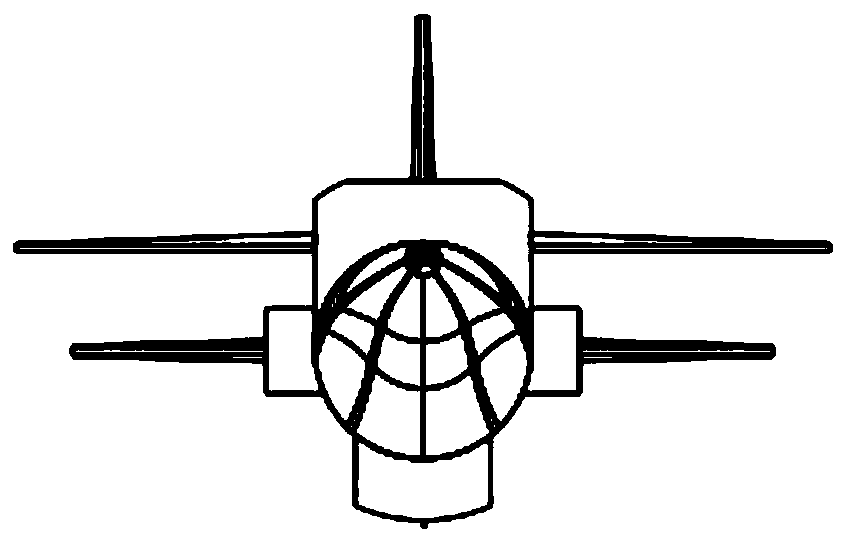

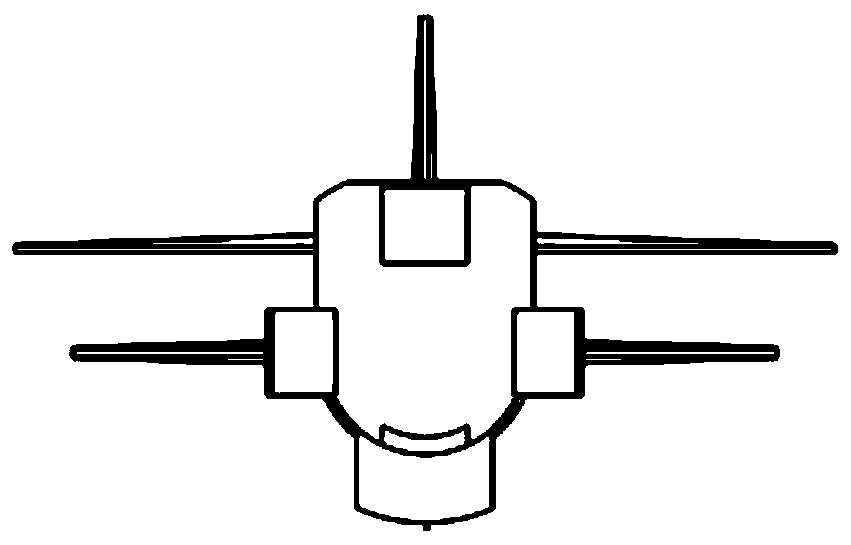

[0050] figure 1 It is the outline drawing of the solid rocket flight test platform (i.e. solid rocket vehicle) provided by the present embodiment; figure 2 It is the front view of the solid rocket flight test platform provided by this embodiment; image 3 It is the rear view of the solid rocket flight test platform provided by this embodiment; Figure 4 It is a side view of the solid rocket flight test platform provided by this embodiment; Figure 5 It is a top view of the solid rocket flight test platform provided by this embodiment. Figure 6 It is the ballistic schematic diagram provided by this embodiment.

[0051] Such as Figure 1 to Figure 5 As shown, the aerodynamic layout of the solid rocket flight test platform includes: head load compartment 1, rocket body 2, two wings 3, one rudder 4, two horizontal tail rudders 5, engine nozzle outlet 6, adjustable gas flow Baffle plate 7, inclined buffer device 8. Among them, the load compartment 1 is connected to the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com