Method for cleaning lens packing plates

A technology for packaging plates and lenses, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

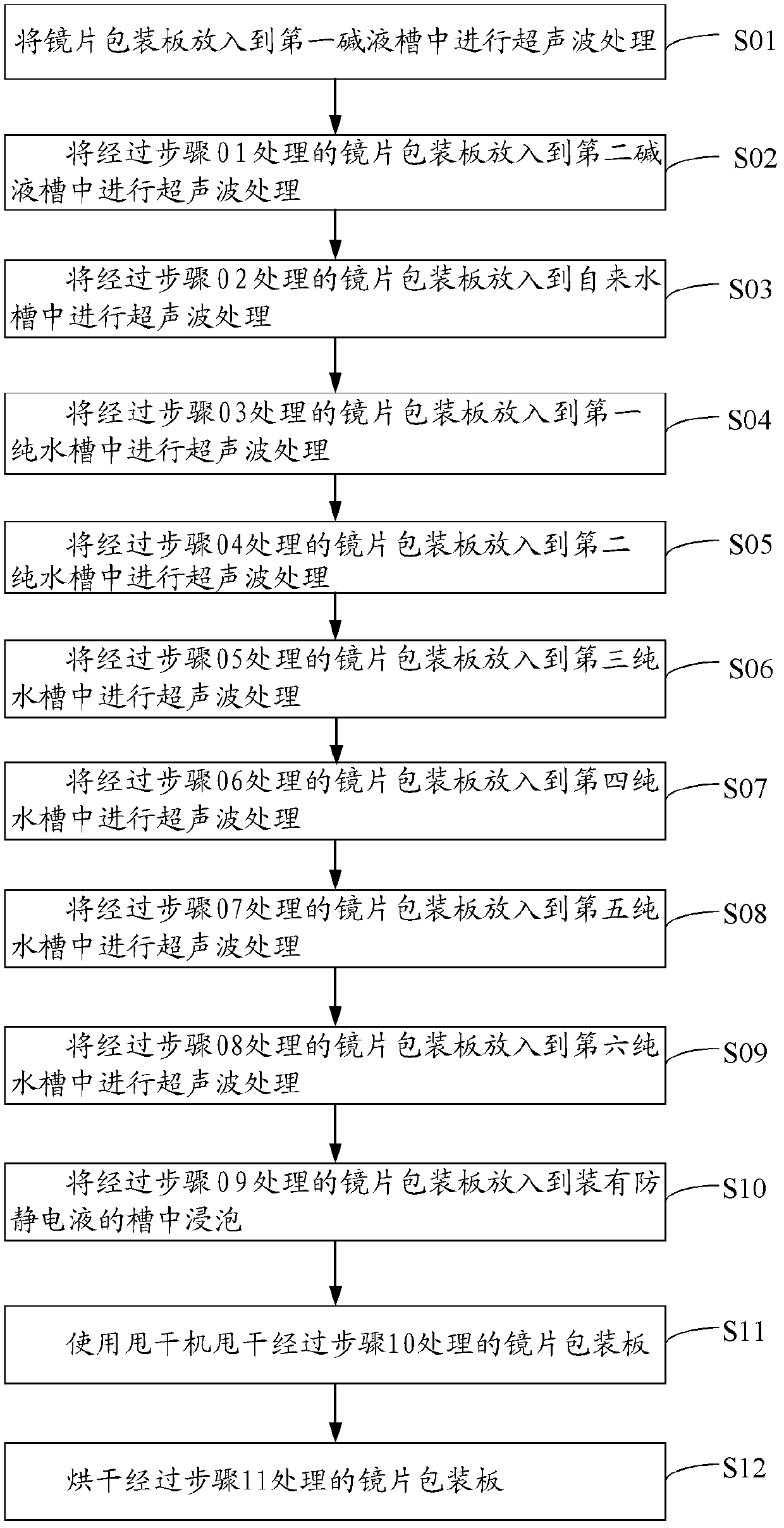

[0028] The method for cleaning the above-mentioned lens packaging plate will be further elaborated below through specific embodiments and accompanying drawings.

[0029] see figure 1 , a lens packaging plate cleaning method of an embodiment, comprising the following steps:

[0030] Step S01: Put the lens packaging board into the first lye tank for ultrasonic treatment.

[0031] Alkaline solution is housed in the first lye tank. In this embodiment, the alkaline solution is prepared from Rishun RSB-26 cleaning agent and water. The mass percentage of Rishun RSB-26 cleaning agent is 5%. Before use, first filter the alkaline solution with a filter element with a pore size of less than 5 microns to remove impurities in the water and improve the cleaning effect.

[0032] The formula of Rishun RSB-26 cleaning agent is water, trisodium phosphate, sodium silicate, sodium citrate, sodium alkylbenzene sulfonate, and alkylphenol polyoxyethylene ether. This cleaning agent can better re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com