Sterilization of packaging containers

A technology for packaging containers and sterilized water, which is applied in the directions of packaging sterilization, packaging, transportation and packaging, and can solve problems such as limiting cooling effect and shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

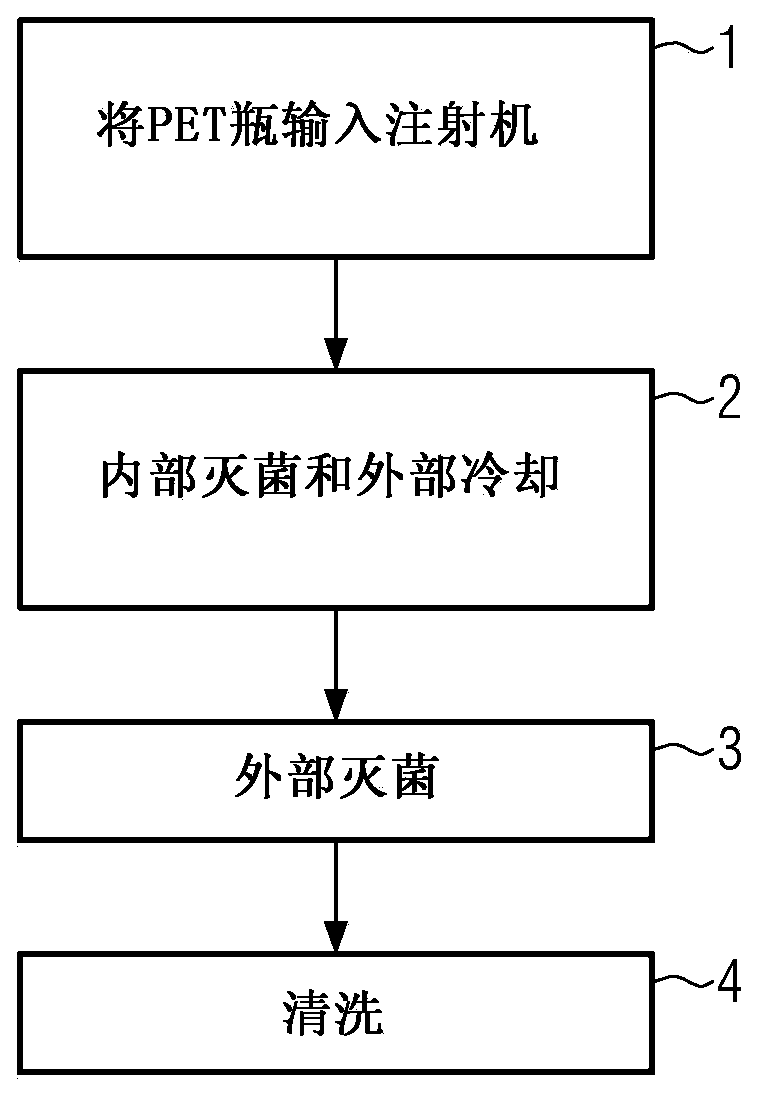

[0027] figure 1 The steps of the sterilization method for PET bottles to be filled are shown. The PET bottles are conveyed, for example, by means of a continuous conveyor into the injection machine, for example as it is described in EP1144016B11. The injection machine has a rotary part with accommodation for PET bottles. A mixing nozzle for blowing a mixture of water vapor and disinfectant into the interior of the PET bottle for internal sterilization 2 is installed on the turntable of the turntable. The mixing nozzle can be a two-component spray nozzle. Cooling of the outer wall of the PET bottle is performed simultaneously with internal sterilization 2. In order to achieve a high degree of sterilization, a mixture of water vapor and disinfectant is blown into the interior of the PET bottle at very high temperatures, in particular above 95° C., where it deposits on the inner wall. In order to eliminate shrinkage of the PET bottles during the internal sterilization 2, cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com