Method for biologically purifying industrial circulating water

A technology for industrial circulating water and biological purification, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The production volume and the heat exchange efficiency of the heat exchanger are reduced to achieve the effects of reducing the dosage of chemicals, reducing corrosion and perforation, and increasing the concentration multiple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

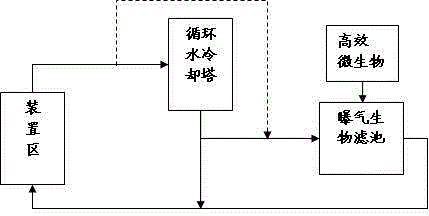

Image

Examples

Embodiment 1

[0034] The preparation method of embodiment 1 denitrifying bacteria agent

[0035] 1. Bacterial activation: The formula of the activating medium of Cochlear palustris FSDN-A is: beef extract: 8g / L, peptone: 12g / L, NaNO 2 : 0.5g / L, KNO 3 : 0.5g / L; the activation medium formula of Arthrobacter FDN-1 and Flavobacterium waterii FDN-2 is: beef extract: 5g / L, peptone: 10g / L, NaNO 2 : 1g / L, add 2.0% agar. Spread evenly on the plate and place it in a constant temperature incubator at 30°C for activation.

[0036] 2. Use the inoculation loop to scrape the bacteria on the plate and inoculate them in the corresponding liquid culture solution respectively, and culture them with shaking under aerobic conditions of 25~35℃ and 150~240rpm for 1~3 days until the logarithmic growth phase, and obtain Liquid bacterial agent seed solution; the formula of the medium is the same as that of the activated medium, without adding agar.

[0037] 3. The above-mentioned Kokia palustris FSDN-A was use...

Embodiment 2

[0040] The circulating water volume of a circulating water plant is 29,000 tons / hour, the COD (chromium method, the same below) of the circulating water influent is 30.2~65mg / L, and the ammonia nitrogen is 2.4~7.9mg / L. Among them, 900 tons / hour of circulating water enters the biological aerated filter (BAF). The operating conditions of the biological aerated filter are: temperature 28°C, pH 7.5, DO 1.5mg / L. First mix the denitrifying and denitrifying bacteria agent A with the activated sludge according to the ratio of MLSS of 1:15, and then add it to the biological aerated filter according to the dosage of MLSS of 1000mg / L. After 20 days, a biofilm was formed. At this time, according to the dosage of 100mg / L of MLSS, nitrifying bacteria were added. After treatment, the ammonia nitrogen and COD in the effluent were always lower than 5mg / L, and the concentration factor of the circulating water was increased from the original 4.5. Up to 5.8, the water quality of the circulating w...

Embodiment 3

[0042] In the circulating cooling water system of a large domestic petrochemical refinery, the total amount of circulating water is 25,000 tons / hour, the control cycle concentration ratio is 2.7, the supplementary water volume is 600 tons / hour, the COD of circulating water is 60.2~79mg / L, and the ammonia nitrogen is 7.2 ~12.9mg / L. The aeration raw filter is used to partially treat the circulating cooling water after the cooling tower, and the circulating water volume is 1100 tons / hour. First mix denitrifying agent B and activated sludge according to the ratio of MLSS of 1:20, and then add it to the biological aerated filter according to the dosage of 1500mg / L after mixing. Membrane formation, start to add nitrifying bacteria according to the dosage of 80mg / L of MLSS. The operating conditions of the biological aerated filter are: temperature: 32°C, pH: 7.8, DO: 2.0mg / L. After treatment, the ammonia nitrogen in the effluent water is lower than 5mg / L, and the COD is always lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com