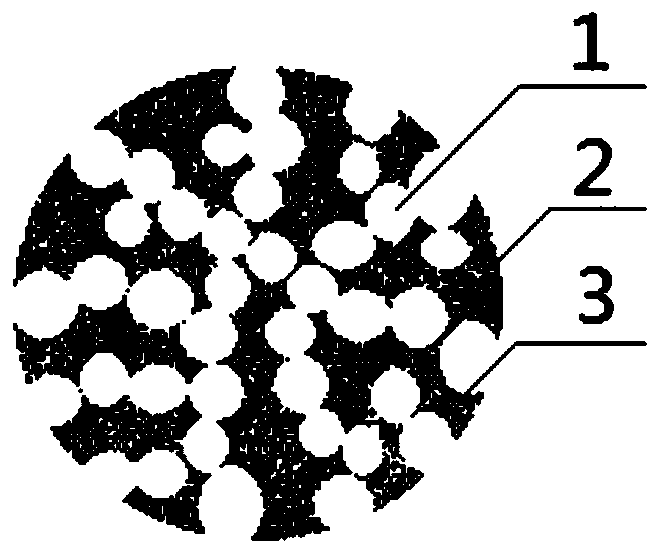

Honeycomb-shaped biological filler suitable for microbiologic treatment of wastewater as well as preparation method and application thereof

A technology of microbial treatment and biological filler, which is applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of enriching the multi-level pore structure, activating the growth of microorganisms and reducing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

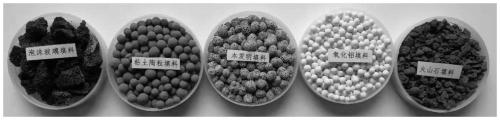

Embodiment 1

[0037]After the mineral material is crushed to 100-150 meshes, it is accurately weighed according to the formula, and then mixed to make an embryo. After the embryo is dried, it is roasted to obtain a finished product. The preparation process of the kit is as follows: Accurately weigh 12.5 grams of silica airgel; 10 grams of Y-type molecular sieve; 25 grams of expanded perlite; 5 grams of expanded vermiculite; 25 grams of diatomaceous earth; 45 grams of light calcium carbonate; 5 grams of stone; 5 grams of medical stone; 2.5 grams of magnesium oxide; 5 grams of iron oxide; 2.5 grams of nickel oxide; 0.5 grams of copper oxide; 25 grams of polystyrene foam particles; Add 96 grams of water, fully mix, and then granulate on a disc granulator to make the first embryo of the particle. The primary embryo is naturally cured for 6 days in an environment with a humidity of 70%-90% and a temperature of 25°C, baked at 105°C for 2 hours, and then roasted at 220°C for 2 hours. After cooling...

Embodiment 2

[0039] After the mineral material is crushed to 100-150 meshes, it is accurately weighed according to the formula, and then mixed to make an embryo. After the embryo is dried, it is roasted to obtain a finished product. The preparation process is as follows: Accurately weigh 45 grams of silica airgel; 10 grams of ZSM-5 molecular sieve; 5 grams of expanded perlite; 20 grams of expanded vermiculite; 10 grams of diatomite; 15 grams of light calcium carbonate 10 grams of tourmaline; 5 grams of medical stone; 10 grams of magnesium oxide; 40 grams of iron oxide; 2.5 grams of nickel oxide; 0.5 grams of copper oxide; 50 grams of polyurethane foam particles, 300 grams of aluminate cement, after mixing evenly, Add 209 grams of water, fully mix, and then granulate on a disc granulator to make the first embryo of the particle. The primary embryo is naturally cured for 4 days in an environment with a humidity of 70%-90% and a temperature of 25°C, baked at 100°C for 3 hours, and then roaste...

Embodiment 3

[0041] After the mineral material is crushed to 100-150 meshes, it is accurately weighed according to the formula, and then mixed to make an embryo. After the embryo is dried, it is roasted to obtain a finished product. The preparation process of the kit is as follows: Accurately weigh 30 grams of silica airgel; 10 grams of Y-type molecular sieve; 10 grams of expanded perlite; 5 grams of expanded vermiculite; 15 grams of diatomite; 20 grams of light calcium carbonate; 25 grams of stone; 25 grams of medical stone; 5 grams of magnesium oxide; 10 grams of iron oxide; 5 grams of nickel oxide; Finally, add 156 grams of water again, fully mix, and then granulate on the disc granulator to make the first embryo of the particle. The primary embryo is naturally cured for 7 days in an environment with a humidity of 70%-90% and a temperature of 25°C, baked at 105°C for 2 hours, and then roasted at 200°C for 2 hours. After cooling, the honeycomb filler is obtained, named Sample No. 3, its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com