A kind of lithium-sulfur battery cathode carrier material and preparation method thereof

A lithium-sulfur battery and carrier material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as large size, poor battery cycle performance, and low active material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (4) Preparation of positive electrode materials for lithium-sulfur batteries: mix the materials prepared in Examples and Comparative Examples with sulfur elemental substance at a mass ratio of 1:4, and ball mill for 30 minutes to obtain the mixture, and then transfer the mixture to polystyrene in an argon atmosphere. Seal the reactor in vinyl fluoride, and heat the reactor at 155°C for 24 hours in a muffle furnace. Finally, it was naturally cooled to room temperature to obtain the cathode material for lithium-sulfur batteries.

[0034] (5) Assembly of the battery: the positive electrode material of the lithium-sulfur battery is used as the positive electrode; the lithium sheet is used as the negative electrode; the electrolyte solvent is 1,3-dioxolane (DOL) and ethylene glycol dimethyl ether (DME), and the volume The ratio is 1:1, the solute is 1mol / L lithium bistrifluoromethanesulfonate imide (LiTFSI), 0.2mol / L lithium nitrate (LiNO 3 ); the diaphragm adopts the polyp...

Embodiment 1

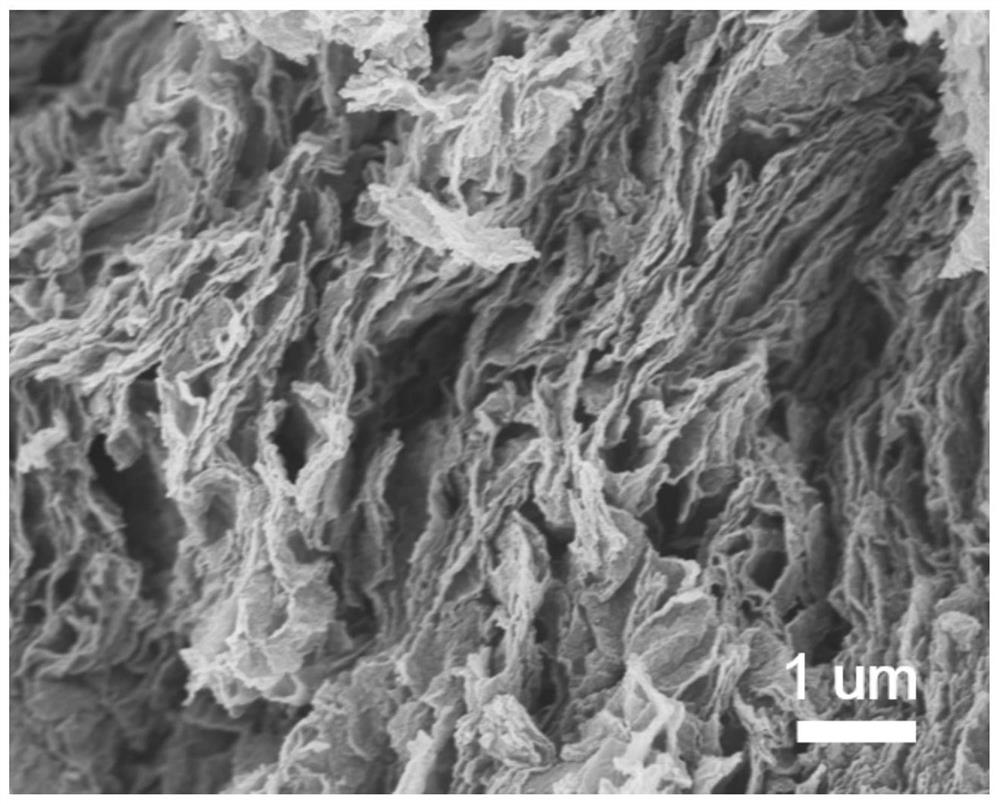

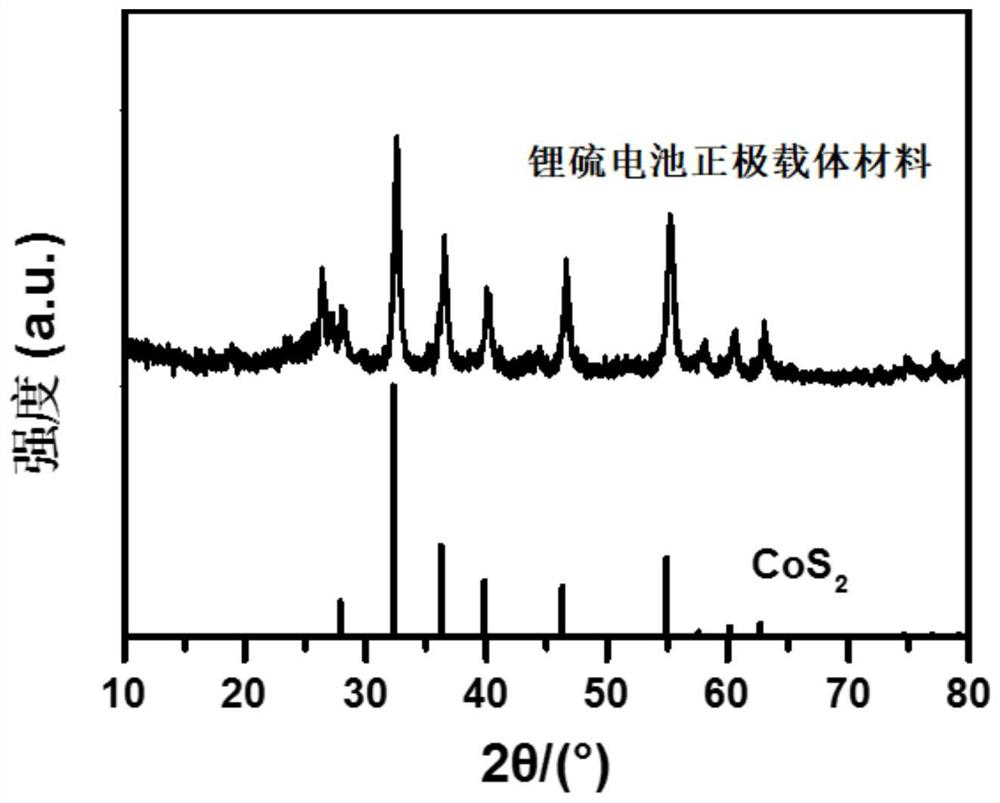

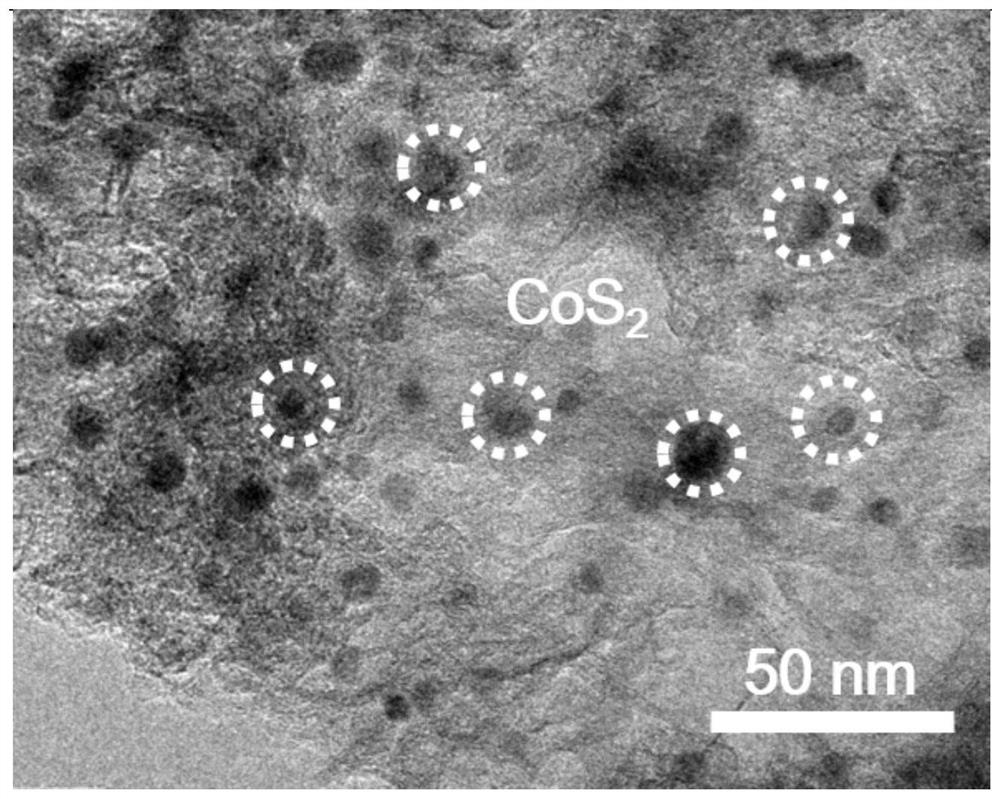

[0038] At room temperature, 200 mg of polyvinylpyrrolidone was dissolved in 40 mL of methanol solution, 2 mL of graphene oxide aqueous solution (10 mg / ml) was added to the above solution, and ultrasonically dispersed for 2 hours to obtain mixed solution 1. 1.19g Zn(NO 3 ) 2 ·6H 2 O and 0.58g Co(NO 3 ) 2 ·6H 2 O was dissolved in mixed solution 1 and stirred at room temperature for 3 h to obtain mixed solution 2. Then the methanol solution of 40mL 2-methylimidazole (1.97g) was quickly added to the mixed solution 2, stirred at room temperature for 30min until the purple-black precipitate was produced and then centrifuged, and the gained purple-black precipitate was washed 3 times with anhydrous methanol to remove impurities. Then it was washed twice with deionized water, and the obtained purple-black precipitate was freeze-dried in a freeze dryer for 48 hours to obtain intermediate product 1. The intermediate product 1 was calcined in an argon atmosphere tube furnace at 900...

Embodiment 2

[0048] At room temperature, 200 mg of polyvinylpyrrolidone was dissolved in 40 mL of methanol solution, 2 mL of graphene oxide aqueous solution (10 mg / ml) was added to the above solution, and ultrasonically dispersed for 2 hours to obtain mixed solution 1. 0.89g Zn(NO 3 ) 2 ·6H 2 O and 0.87g Co(NO 3 ) 2 ·6H 2 O was dissolved in mixed solution 1 and stirred at room temperature for 3 h to obtain mixed solution 2. Then the methanol solution of 40mL 2-methylimidazole (1.97g) was quickly added to the mixed solution 2, stirred at room temperature for 30min until the purple-black precipitate was produced and then centrifuged, and the gained purple-black precipitate was washed 3 times with anhydrous methanol to remove impurities. Then it was washed twice with deionized water, and the obtained purple-black precipitate was freeze-dried in a freeze dryer for 48 hours to obtain intermediate product 1. The intermediate product 1 was calcined in an argon atmosphere tube furnace at 900...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com