Indium gallium zinc oxide as well as preparation method and application thereof

A technology of indium gallium zinc oxide and indium gallium oxide, which is applied to the production of indium gallium zinc oxide targets, the composition of indium gallium zinc oxide targets, and the field of indium gallium zinc oxide targets, can solve the problem of Problems such as abnormal discharge effect of IGZO target material, deterioration of IGZO film quality and characteristics, uneven mixing, etc., achieve the effect of simplifying production complexity, improving quality and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1-making IGZO

[0048] 1. Fabrication of binary metal oxides

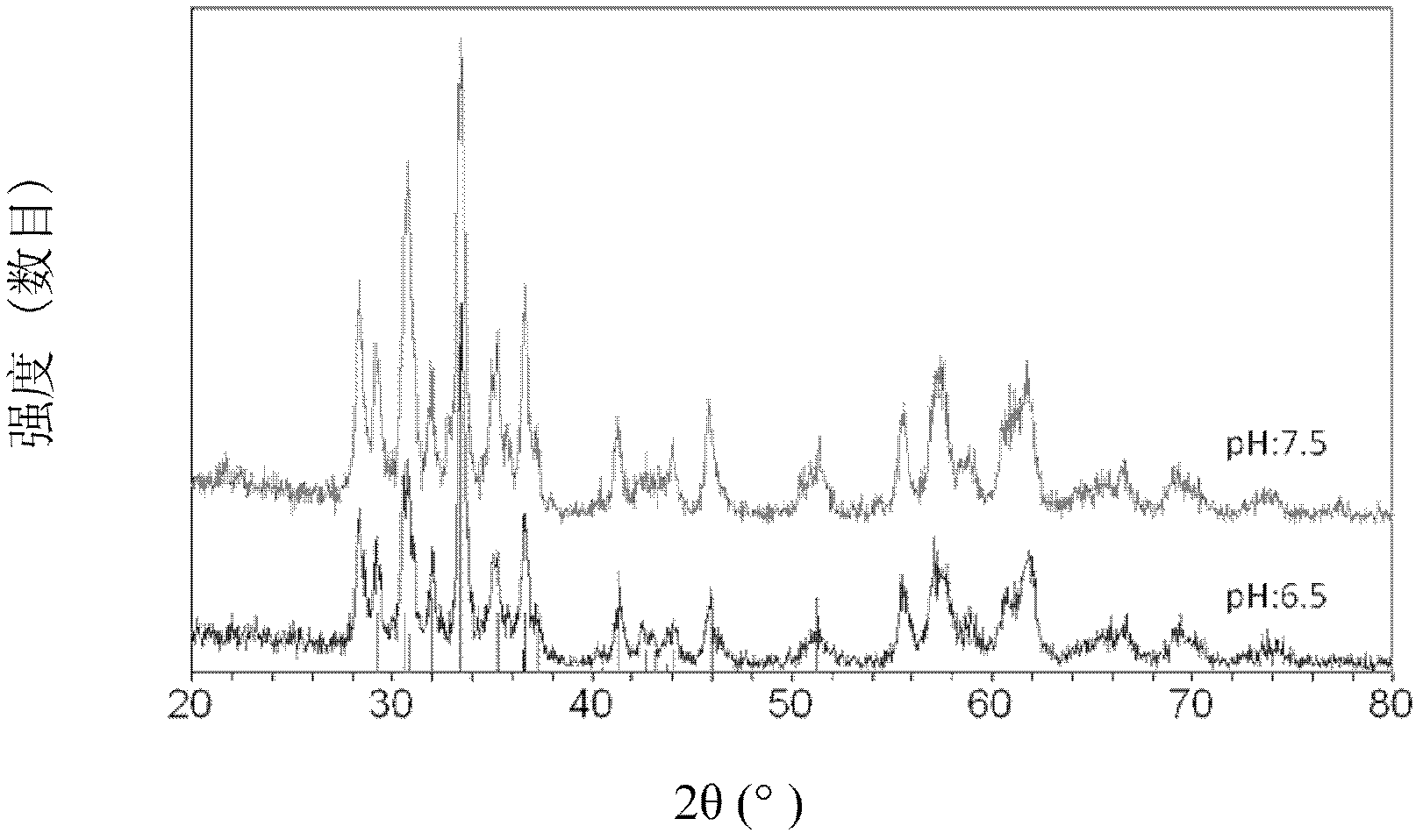

[0049] Metal indium and metal gallium with a purity above 4N (99.99%) are put into a nitric acid solution for acid dissolution to form an initial solution. Ammonium hydroxide aqueous solution is added dropwise into the starting solution to adjust the pH value of the starting solution to 6.5 or 7.5.

[0050] Afterwards, the starting solution was left to stand for 1 hour to perform an aging step, forming a binary metal-containing precipitate. Herein, the binary metal-containing precipitate is indium gallium hydroxide.

[0051] Next, the precipitate containing binary metals is filtered and washed several times to remove unnecessary impurities, and then placed in an oven at 90°C for drying, and after being ground into powder, it is kept at a constant temperature of 700°C Calcined for 1 hour to obtain indium gallium oxide powder.

[0052] Inductively coupled plasma-mass spectroscopy (ICP) was used ...

Embodiment 2

[0058] Example 2 - Making IGZO

[0059] Metal indium and metal gallium with a purity above 4N (99.99%) are put into a nitric acid solution for acid dissolution to form an initial solution containing binary metal oxides. Afterwards, excessive zinc monoxide is added, and ammonium hydroxide aqueous solution is added dropwise to adjust the pH value of the solution to 6-8. When the pH value is adjusted to an appropriate range, indium ions, gallium ions and zinc ions in the initial solution will produce coprecipitation reactions.

[0060] Afterwards, the starting solution was aged for 1 hour to obtain a precipitate containing indium, gallium and zinc. Here, the precipitate containing indium, gallium and zinc is a precipitate of indium gallium zinc hydroxide.

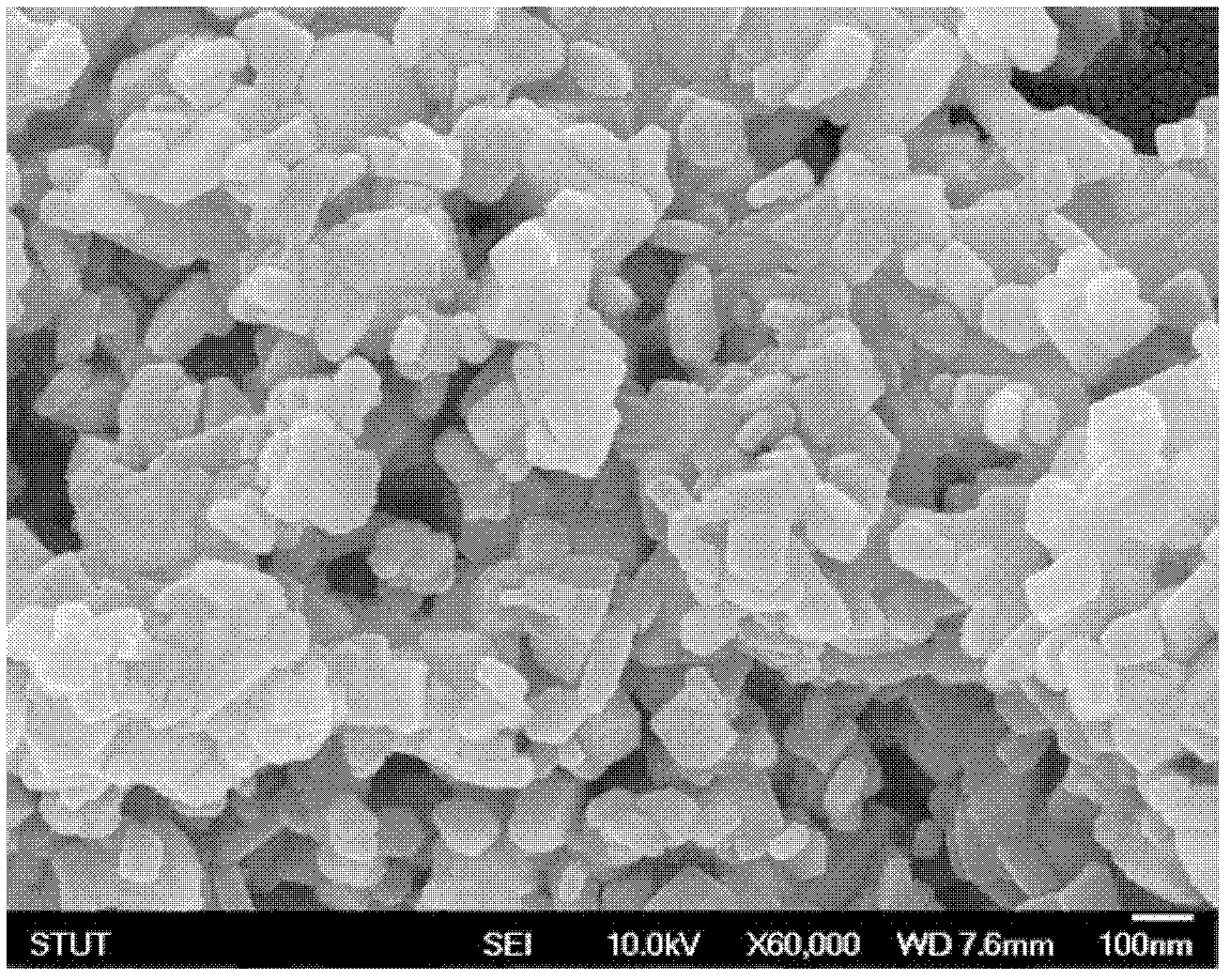

[0061] Next, the precipitate of indium gallium zinc hydroxide is filtered and washed many times to remove unnecessary impurities, then placed in an oven at 90°C for drying, and then ground into powder, at a constant temperat...

Embodiment 3

[0063] Example 3 - making IGZO target

[0064] Use the IGZO powder prepared in Example 1 or Example 2, and ball mill it to less than 0.3 μm, and then mold it by cold isostatic pressing or slip casting to obtain a green embryo. Afterwards, the green embryo is degreased and sintered at a temperature of 1480° C. for 10 hours to obtain an IGZO target with a relative density greater than 95%.

[0065] Through the production method described in Example 1 or Example 2, high-purity InGaZnO with an atomic ratio close to 1:1:1 can be successfully prepared 4 powder.

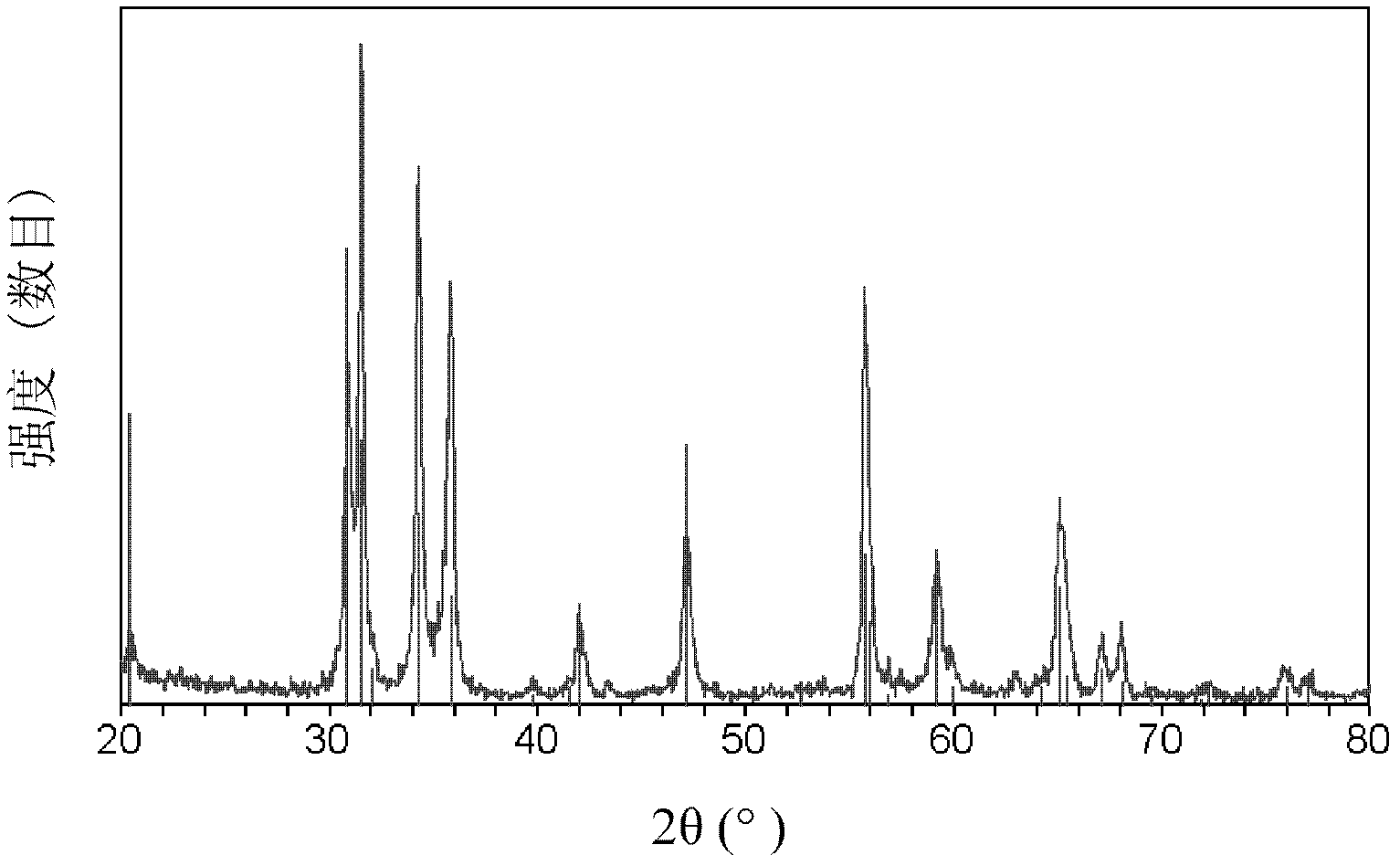

[0066] see Figure 5 As shown, its XRD absorption peak is InGaZnO 4 characteristic peaks, but no ZnGa 2 o 4 The characteristic peaks show that the IGZO target with uniform composition can indeed be prepared by using the manufacturing method described in the present invention.

[0067]Accordingly, the present invention uses uniform binary metal oxide or IGZO powder as the raw material for making IGZO targets, which can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com