Method for preparing zone-melting silicon materials by using zone continuous casting process

A casting method and technology of preparation area, applied in the field of crystal growth, can solve problems such as unparalleled crystal quality advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

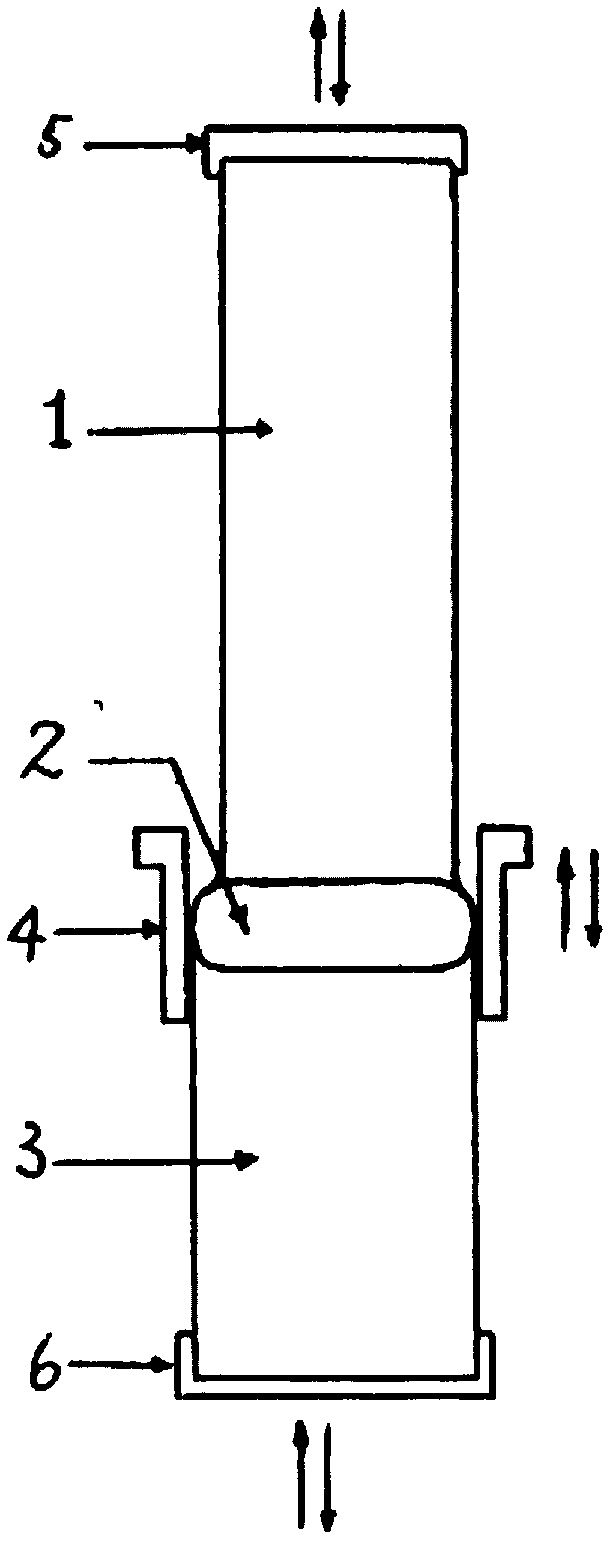

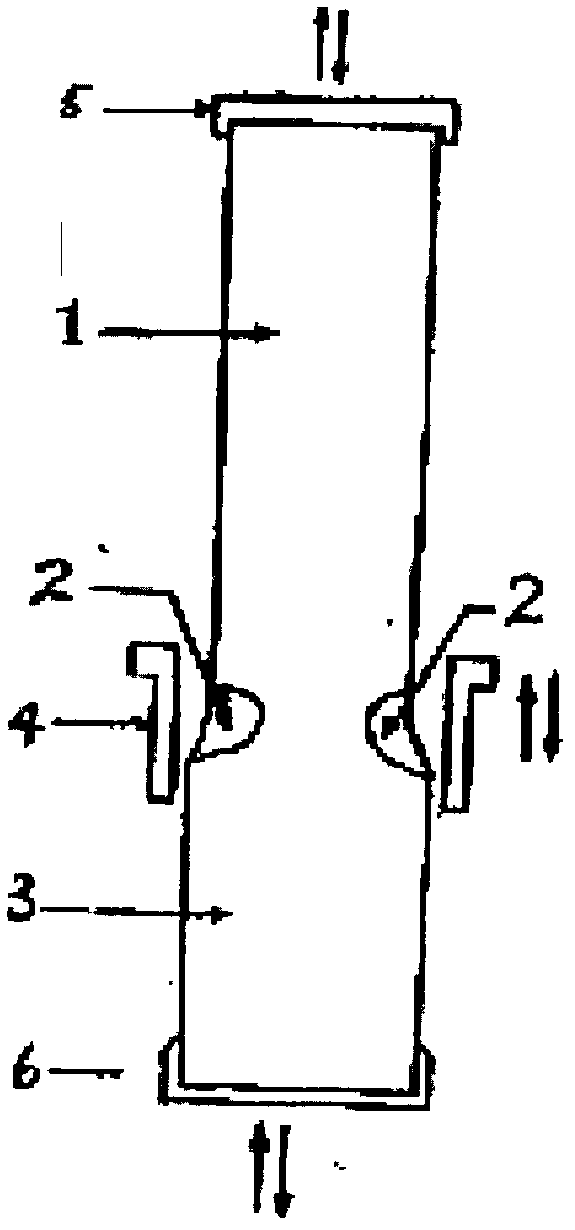

[0012] Such as figure 1 device shown. Ordinary primary reduced silicon rods removed from the reduction furnace (annealing the silicon rods before use is recommended to eliminate internal stress) are clamped on (5) the upper platform of the silicon rods (6) under the silicon rods after the heads of both ends are cut off between platforms. (4) The crucible is made of copper, molybdenum and other metals or ceramics, and the built-in water cooling circuit heats the molten silicon through the induction coil.

[0013] When casting crystals, (2) The melting zone of molten silicon can be cast from the top of the silicon rod from top to bottom, or from the bottom to the top.

[0014] When casting the crystal, (4) the water-cooled crucible and the heater can be fixed, and the silicon rod moves up and down for casting. The silicon rods can also be relatively fixed, and the (4) water-cooled crucible and heater can be moved for casting. No matter which physical movement method is used,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap