Air inlet plate with structure improved and for air channel of cotton-spinning combing machine

A structure improvement and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problems of increased head box temperature rise, difficult air flow compensation, and inability to clean the bottom side of the head box, etc., to achieve Cleaning aid reduces and improves air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

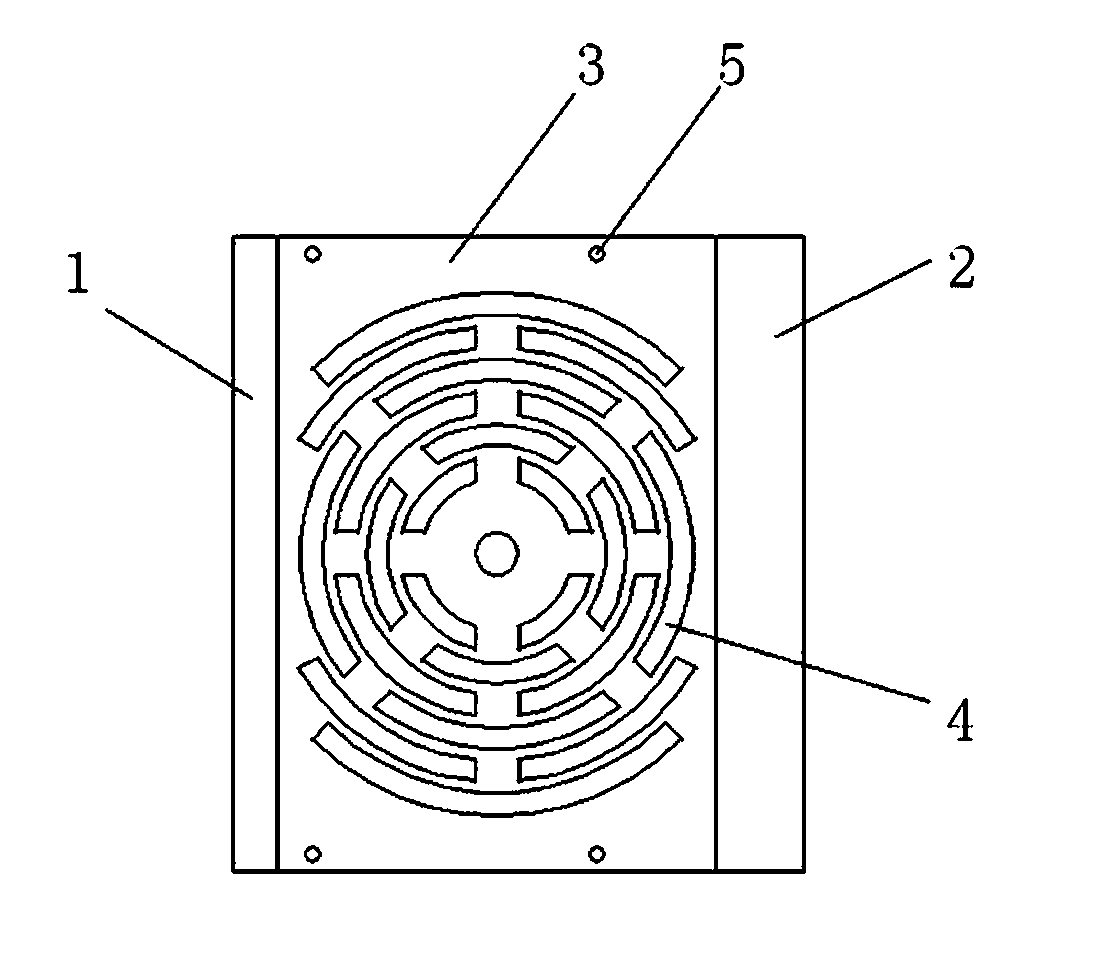

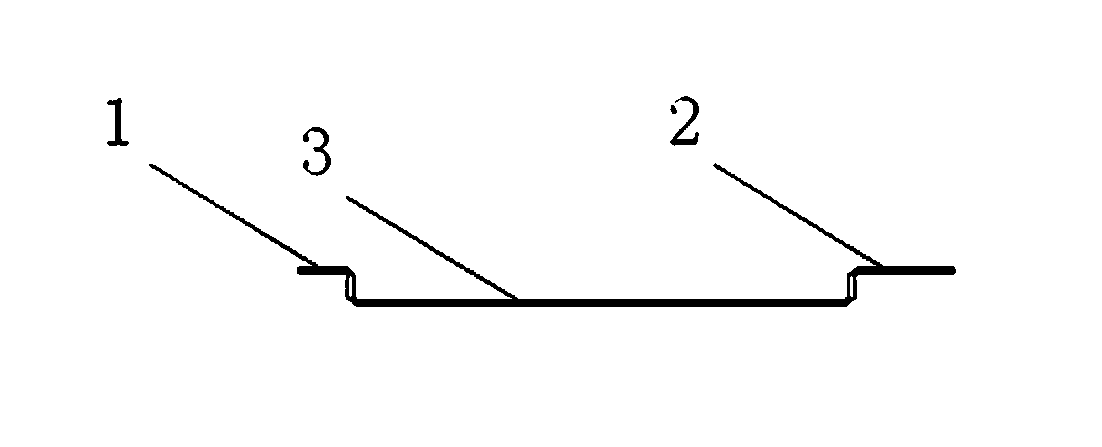

[0013] Embodiment: A structure-improved air inlet plate for the air duct of a cotton spinning comber, which is fixed on the flange on the head side flange of the air duct of the comber, and the air inlet plate includes left and right air suction plates 1, 2 and a central The air supply plate 3, the left and right air suction plates 1 and 2 are fixed on both sides of the central air supply plate 3, and the left and right air suction plates 1 and 2 are formed through the flange side wall of the comber air duct head side respectively The left and right air suction passages of the central air supply plate 3 are provided with a supplementary air hole 4, and the two axial sides of the supplementary air hole 4 are connected with the air duct and the bottom side of the head box respectively, and the two ends of the supplementary air hole 4 are respectively connected with the The air duct is corresponding to the rear side of the main motor, so that the supplementary air hole 4 connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com