Side-guide chain for pen making

A technology for side guide wheels and pens, which is applied in the direction of transmission chains, etc., can solve the problems of reduced production efficiency, impact on use time, and easy wear and tear, and achieve the effects of reasonable layout, extended use time, and reasonable structural layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

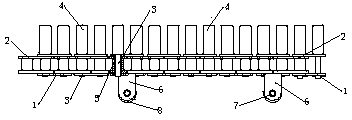

[0010] Combine below figure 1 Specific description embodiment:

[0011] A side guide wheel chain for pen making, characterized in that the side guide wheel chain for pen making is composed of several chain units connected together, and the chain unit includes an outer chain piece 1, an inner chain piece 2 and Step pin 3, both ends of the step pin 3 are pierced with a set of outer chain piece 1 and inner chain piece 2, one end of the step pin 3 passes through the inner chain piece 2 and the outer chain piece 1 and then goes outward A boss 4 is extended, the step pin 3 is covered with a shaft sleeve 5, and the side guide wheel chain for pen making is provided with a number of guide wheel bends 6, and the guide wheel bends 6 are equally spaced Arrangement, described guide wheel curved plate 6 is provided with guide wheel shaft pin 7, and one end of described guide wheel bent plate 6 is connected with guide wheel roller 8.

[0012] Preferably, the distance between adjacent curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com