Two-way buffering transmission gear

A transmission gear, two-way buffer technology, applied in belts/chains/gears, electric vehicles, electric components, etc., can solve the problems of high noise, large impact, uncomfortable riders, etc., to achieve low noise and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

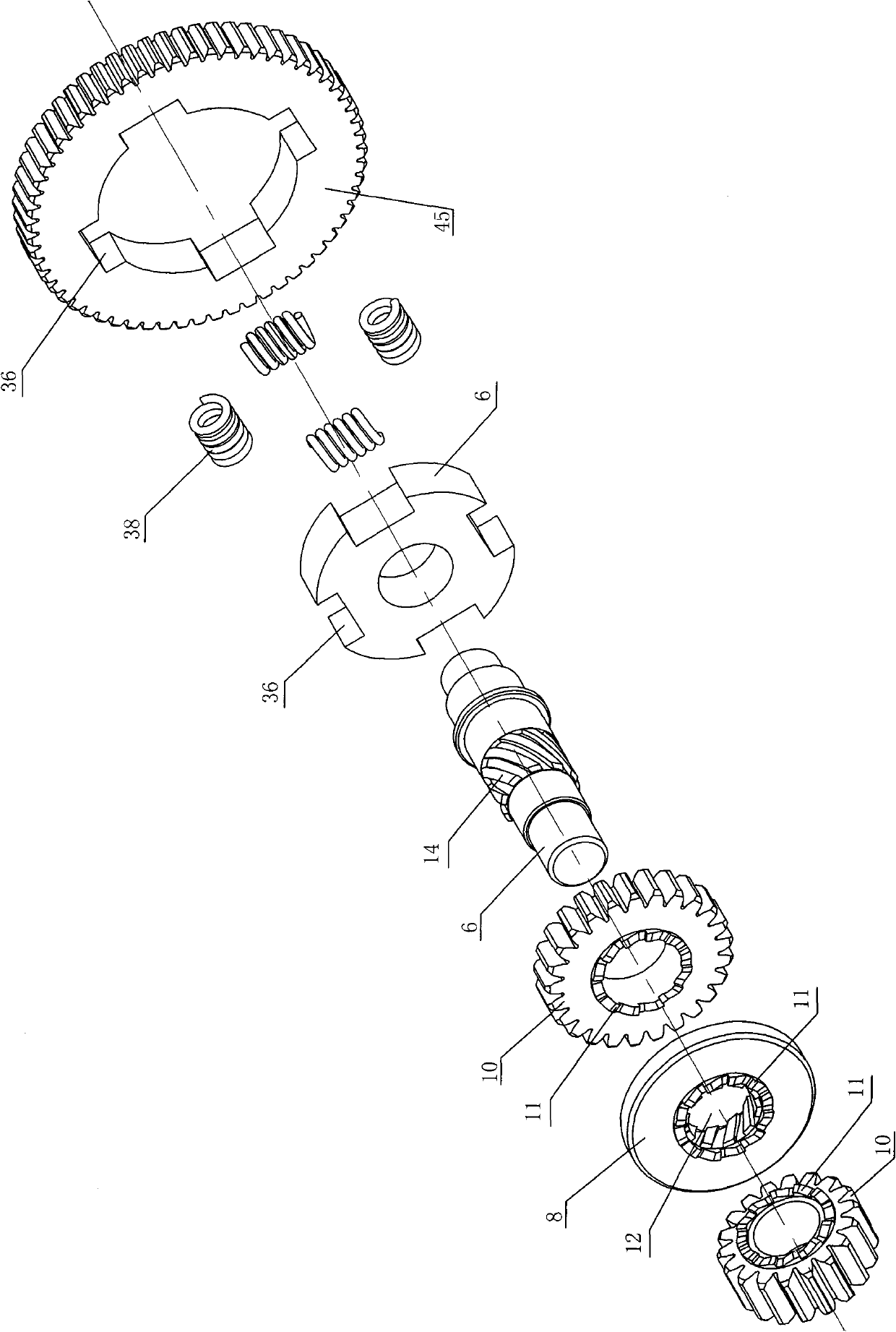

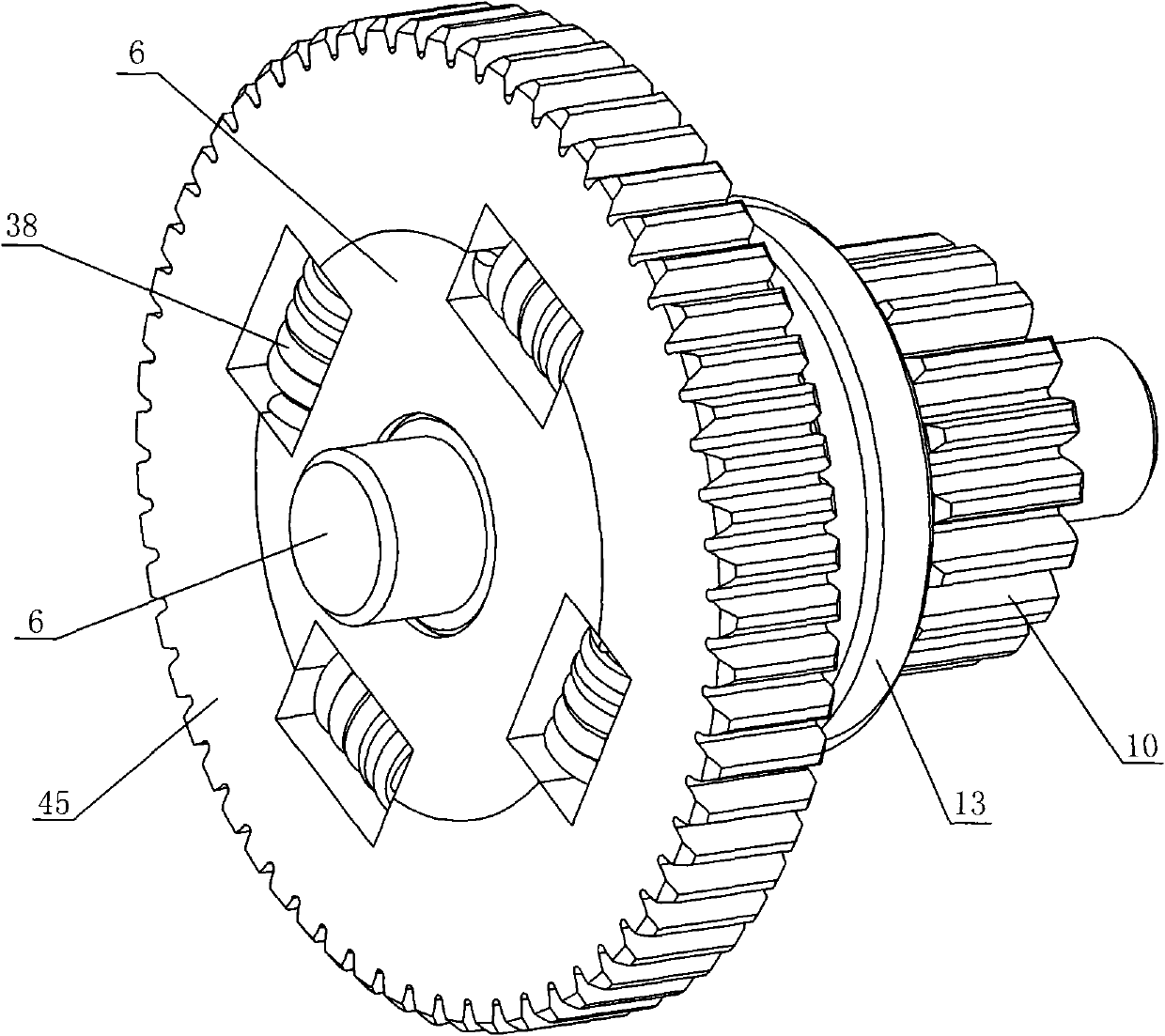

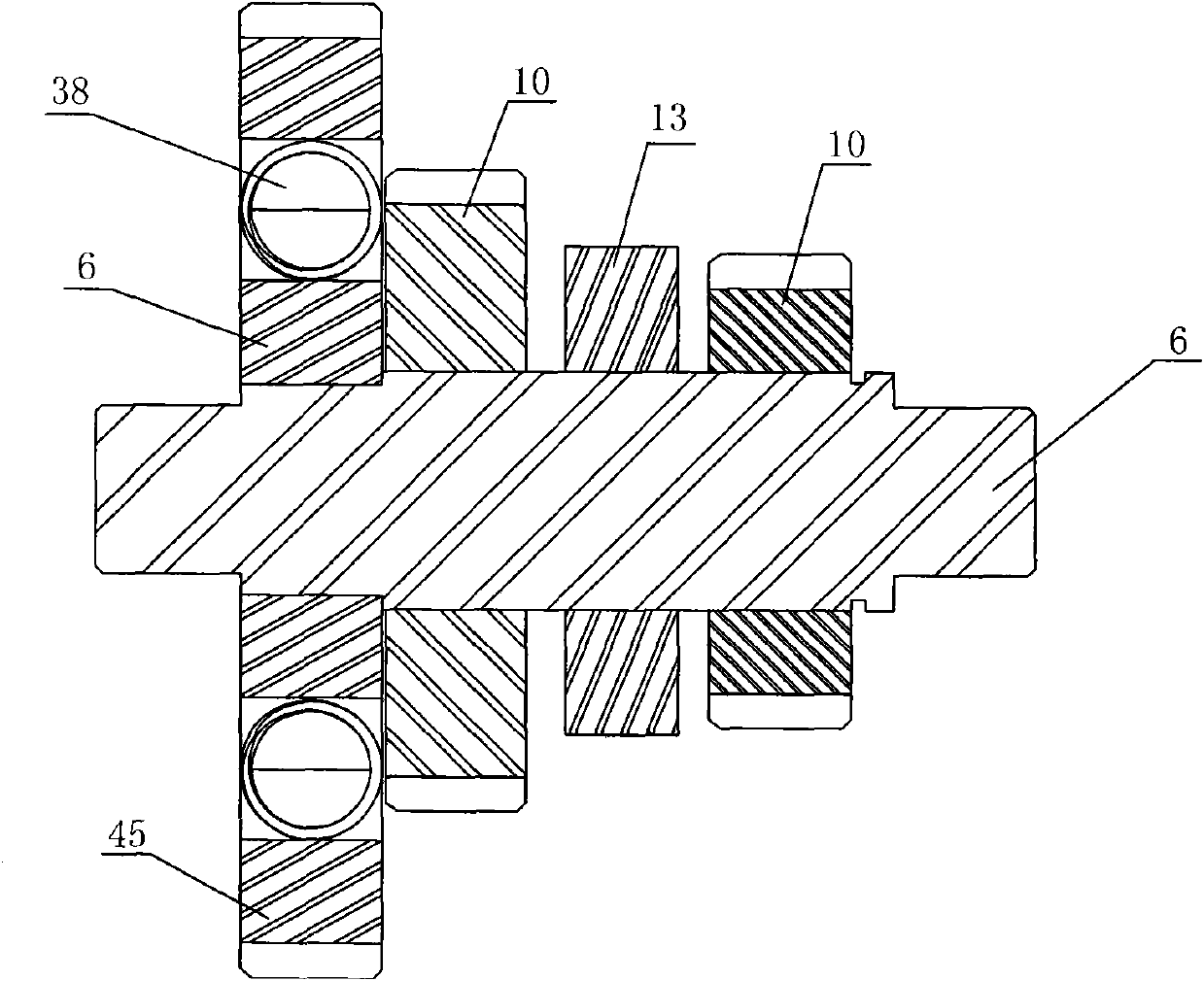

[0014] Such as Figure 1 to Figure 4 As shown, the two-way buffer transmission gear includes a main shaft 6, and an input tooth 45 is set on the main shaft 6. The input tooth 45 and the main shaft 6 are respectively provided with a groove 36, and a damping spring 38 is installed in the groove 36, and the shock absorption The upper part of the spring 38 is fixed on the input tooth 45, and the lower part of the damping spring 38 is supported on the main shaft 6. When the input tooth 45 rotates, the upper part of the main damping spring 38 is stuck, and the lower part of the damping spring 38 is stuck on the main shaft 6. On the other hand, the input tooth 45 can rotate on the main shaft 6 to a limited extent.

[0015] After the motor 3 is energized and rotated, the motor shaft gear 47 rotates to drive the input gear 45 to rotate, and the input gear 45 will first rotate the main shaft 6 by a certain angle, so that the damping spring 38 in the groove 36 is compressed, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com