Non-contact optical fiber device and method for measuring flows

A non-contact, optical fiber measurement technology, applied in measuring devices, optical radiation measurement, fluid flow detection by measuring pressure difference, etc., can solve the problems of destroying the flow field of the pipe flow, inconvenient installation and disassembly, damage, etc., to save energy , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

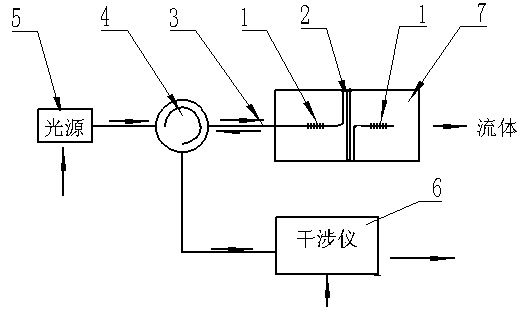

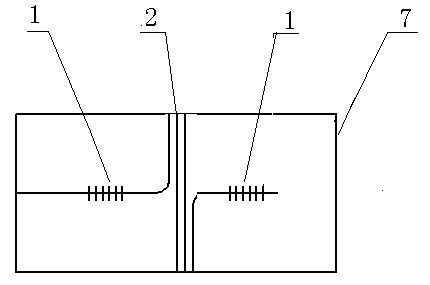

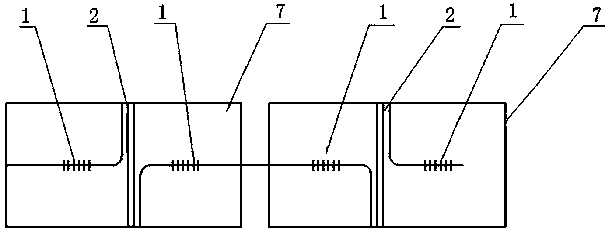

[0021] refer to Figure 1-Figure 5 , a device and method for non-contact fiber optic flow measurement, the device includes a grating 1, a sensing fiber 2, an optical fiber 3, a circulator 4, a light source 5, an interferometer 6, and a pipeline 7. The sensing optical fiber 2 is installed on the pipeline 7, one end of the sensing optical fiber 2 is connected to the grating 1, the optical fiber 3, the circulator 4, and the light source 5 in sequence, and the other end is connected to the grating 1, and the interferometer 6 is connected to the circulator 4. connect.

[0022] The interferometer 6 communicates with the light source 5 through the circulator 4 , and communicates with the optical fiber 3 , the grating 1 and the sensing optical fiber 2 through the output end of the circulator 4 . One end of the sensing fiber 2 is connected to the grating 1, and the other end is connected to the grating 1 or the reflector.

[0023] Non-contact fiber optic flow measuring device The met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com