Optical fiber grating sensing measuring method and device for detecting running state of rotating machine

A fiber grating and operating state technology, applied in the field of sensors, can solve the problems of electromagnetic interference of photoelectric sensors, impossible to accurately grasp the operating state, complicated operation, etc., and achieve the effects of no electromagnetic interference, simple structure, and high measurement stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

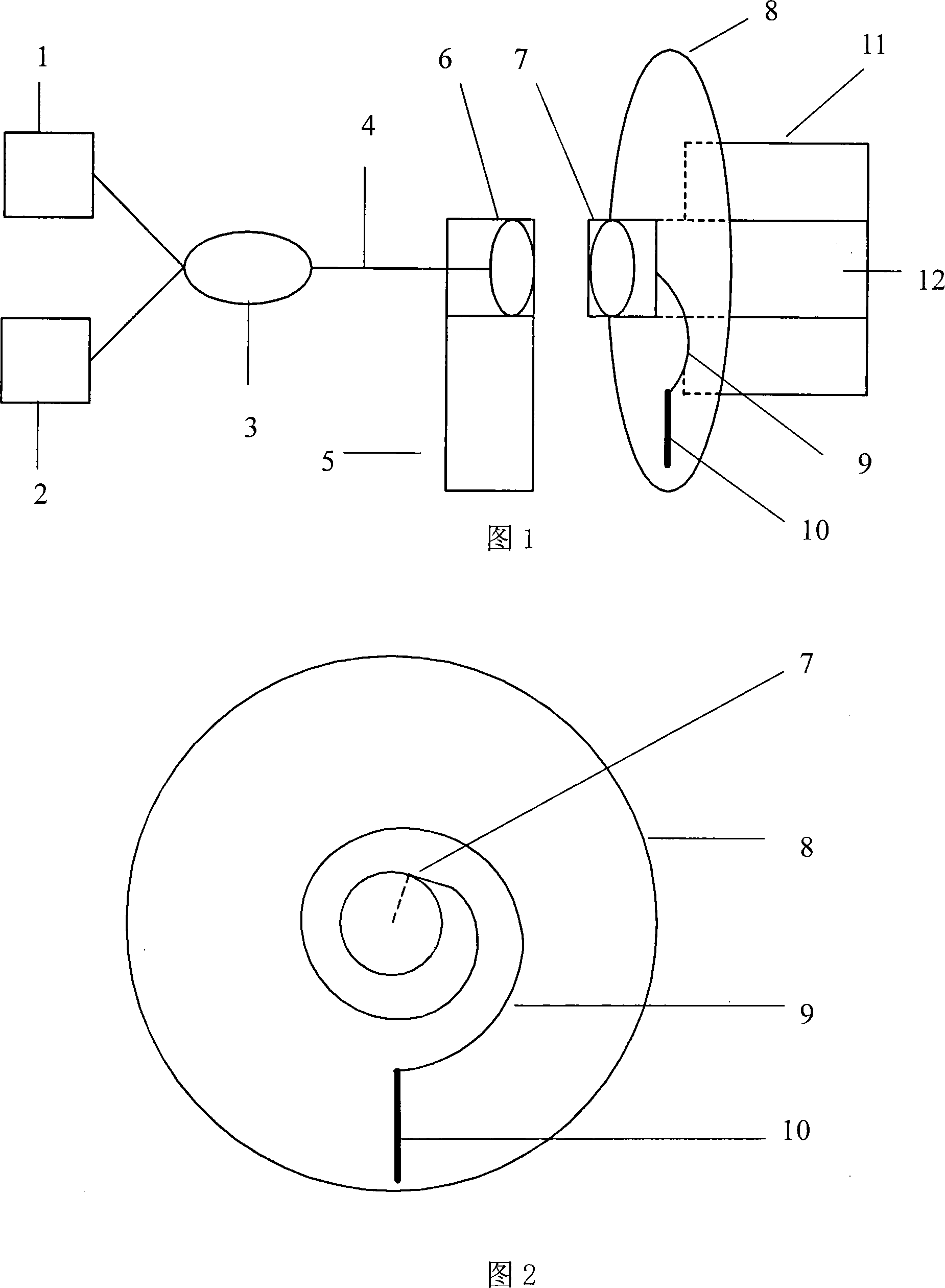

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in Figures 1 and 2, the fiber grating sensing detection method and device for detecting the running state of a rotating machine in the present invention mainly include a light source 1, a fiber grating demodulator 2, a Y-type coupler 3, a transmission fiber 4, a support frame 5, Front collimator 6, rear collimator 7, rotating object 8, transmission fiber 9, fiber grating sensor 10, motor 11, motor spindle 12, fiber grating sensor 10 and transmission fiber 9 are pasted or embedded in the rotating body during detection 8, when the operating state of the rotating body 8 changes, it will cause a change in the grating pitch of the sensing grating, resulting in a shift in the wavelength of the reflected light of the sensing grating, and the reflected light passes through the transmission fiber 4, and then the light emitted by the quas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com