Manufacturing method for dustproof feeding box avoiding waste

A manufacturing method and feeding technology, applied in the application, poultry industry, animal husbandry and other directions, can solve the problems of feed waste, feed splash, etc., and achieve the effects of convenient use, avoidance of feed waste, and simple manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

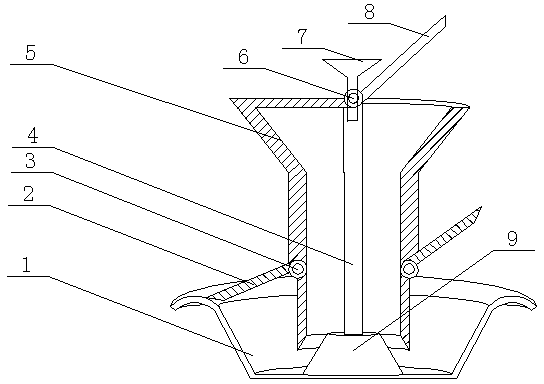

[0026] The present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 as shown, figure 1 It is a schematic diagram of the cross-sectional structure of the invention.

[0027] A method for manufacturing a dust-proof feeding box that avoids waste, wherein the steps are as follows:

[0028] A. Prepare the feed box and the pillar base integrally formed by plastic. The pillar base is in the shape of a circular platform, protruding from the center of the disc-shaped feed box;

[0029] B. Use the prepared pillar made of plastic. The interior of the pillar is hollow, and the central pillar is made at the center of the pillar. The bottom of the central pillar is provided with a ring-shaped support. A passage is formed between the outside of the support and the pillar. On the base, the center column is inserted on the base of the column, so that the column is fixed on the base of the column;

[0030] C. The spring shaft is wound on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com