One-step molding mould for concrete four-face hexagon permeable frame

A technology of permeable frame and forming mold, applied in the direction of mold separation device, etc., can solve the problems of difficult design of prefabricated molds, easy to cause safety accidents, and many construction steps, so as to improve the safety performance and service life, and simplify the construction process. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

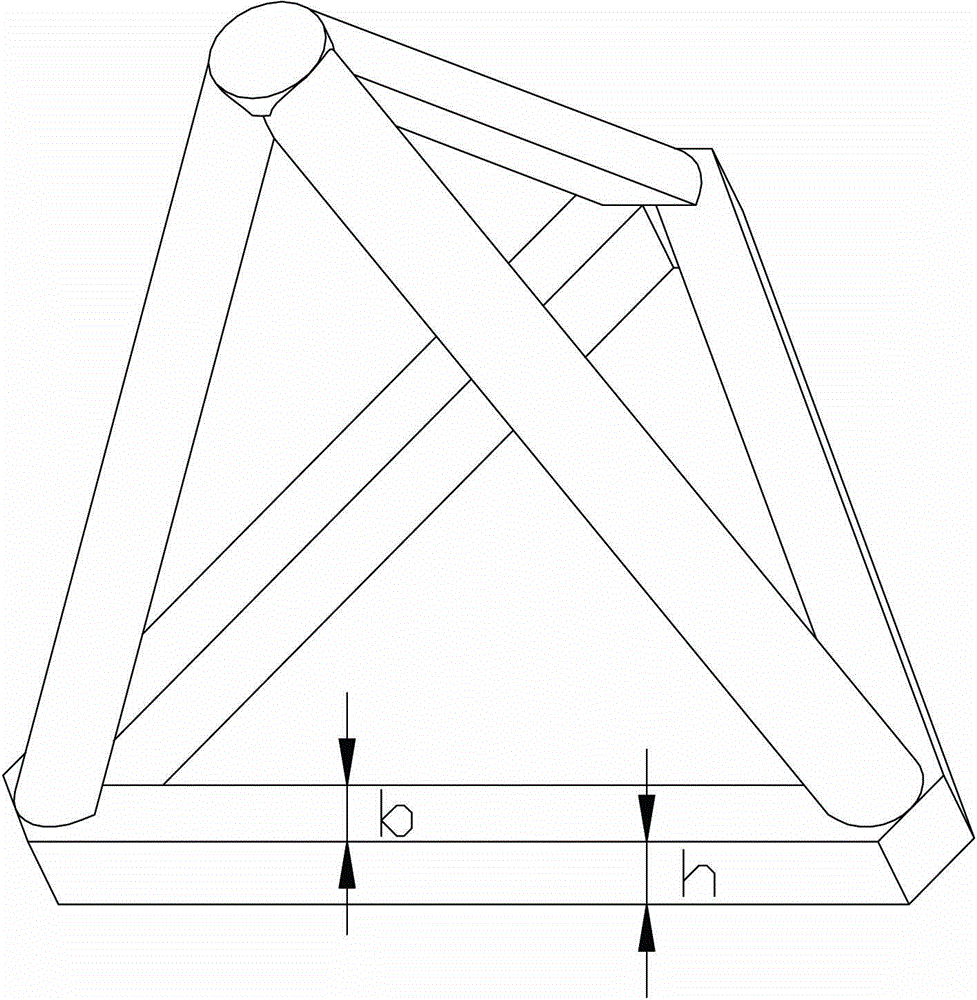

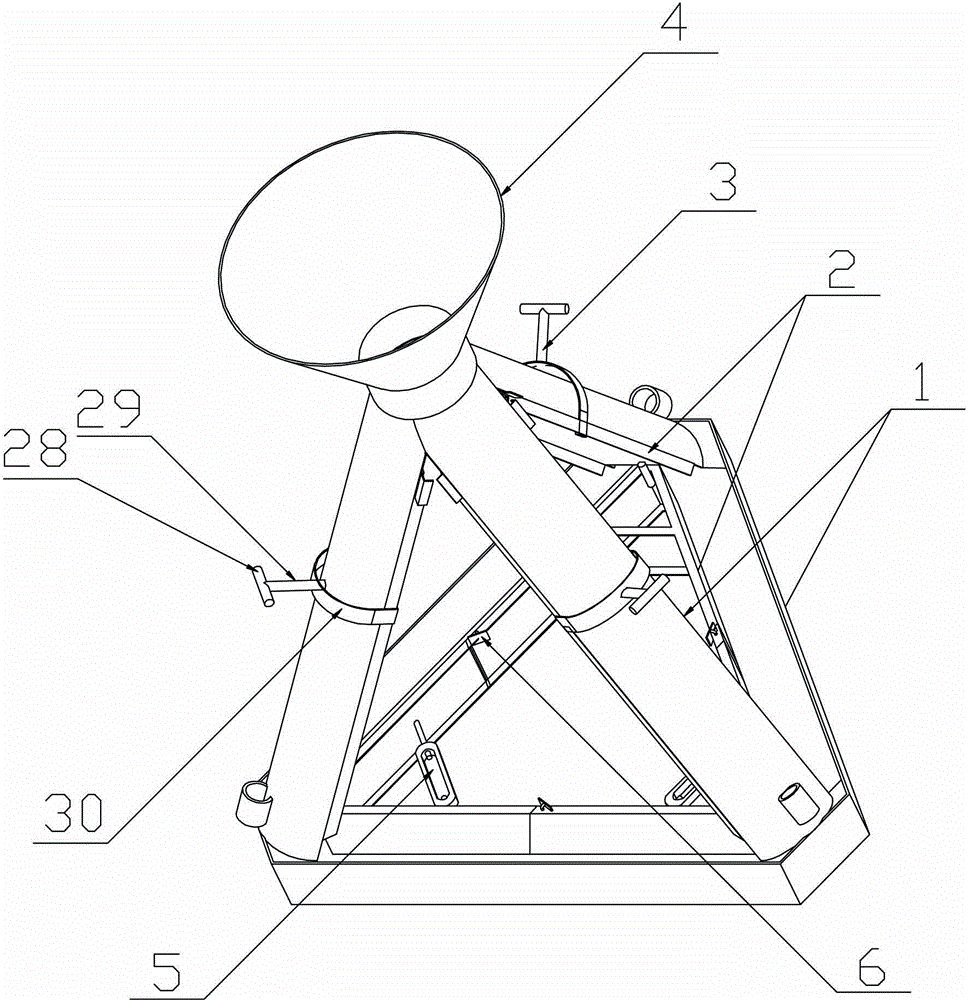

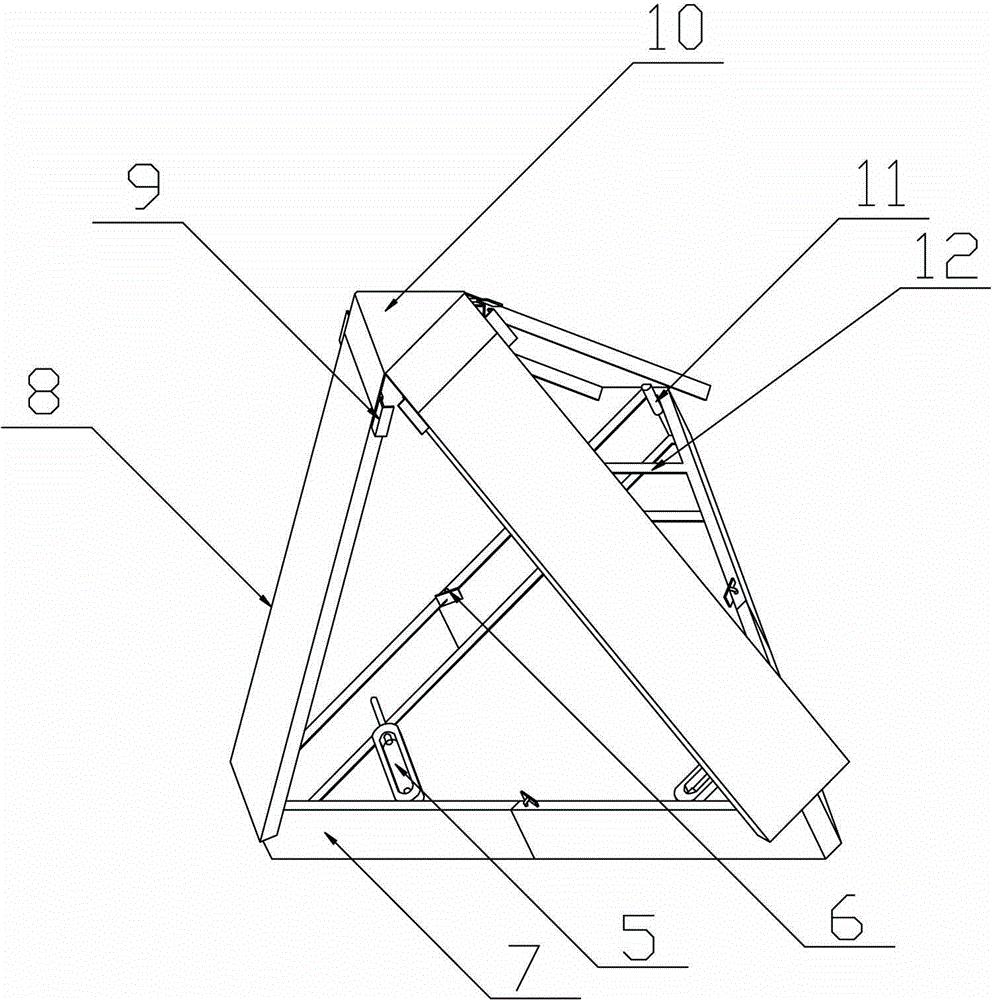

[0023] see figure 2 , the present invention is a four-sided hexagonal permeable frame molding mold for one-time molding concrete, which is composed of an outer mold 1 and an inner mold 2, especially: the inner mold 2, see image 3 , it has a triangular inner frame 7, the triangular inner frame 7 is formed by three A-shaped steel frames 13 with an included angle of 60° butted side by side, and each connection is connected by a detachable connector, wherein there are two The pull bar between the respective two frames in the A-shaped steel frame 13 is the adjustment pull bar 5, see Figure 4 (another A-shaped steel frame 13 is provided with fixed pull rod 12, see Figure 5 ), three oblique baffles 8 of equal length are installed on the three corners of the triangular inner frame 7 (see Figure 6 ), the upper ends of the three inclined baffles 8 are assembled on a top cover 10 (see Figure 7 ), and connected by a living structure; the outer mold 1, see Figure 9 , it has a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com