Hydraulic device for adjusting ascending and descending proportions of snow-removing roll brush

A proportional adjustment, hydraulic device technology, applied in fluid pressure actuation devices, snow surface cleaning, servo motors, etc., can solve the problems of low control accuracy and the inability of the roller brush to clean effectively, so as to improve the accuracy and controllability, solve the Effective contact and weight support to achieve the effect of energy-saving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

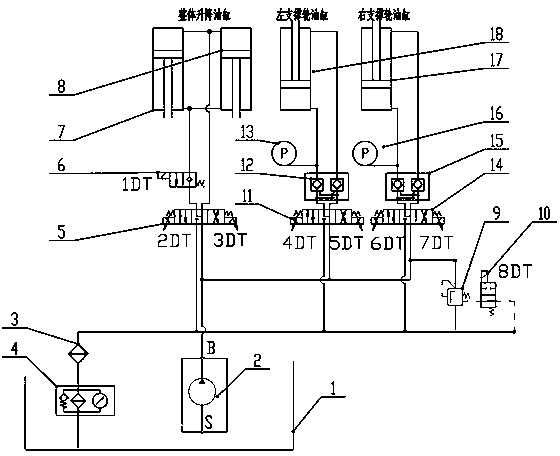

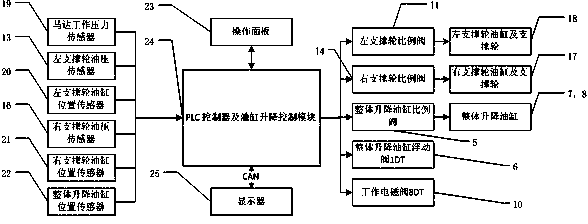

[0010] Such as figure 1 , figure 2 As shown, the present invention includes a hydraulic oil tank 1, an integral lifting cylinder, a left support wheel cylinder 18, a right support wheel cylinder 17 and a set of control systems for a rolling brush lifting cylinder device; the integral lifting cylinder includes an integral lifting left cylinder 7, an integral Lifting right side oil cylinder 8; integral lifting oil cylinder floating valve 6 and integral lifting oil cylinder two-position three-way proportional valve 5 are connected to the integral lifting oil cylinder; left supporting wheel oil cylinder 18 is connected with left supporting wheel oil cylinder large cavity oil pressure sensor 13 and the balance valve 12 of the left support wheel lift cylinder, the balance valve 12 of the left support wheel lift cylinder is connected with the two-position three-way reversing proportional valve 11 of the left support wheel oil cylinder; the right support wheel oil cylinder 17 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com