Gas pipeline check valve

A technology for gas pipelines and check valves, applied in valve details, control valves, valve devices, etc., can solve the problems of inability to judge the normal operation of check valves, poor sealing performance between disc and valve seat, lack of monitoring means for check valves, etc. problem, to achieve the effect of reduced pressure loss, good sealing performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

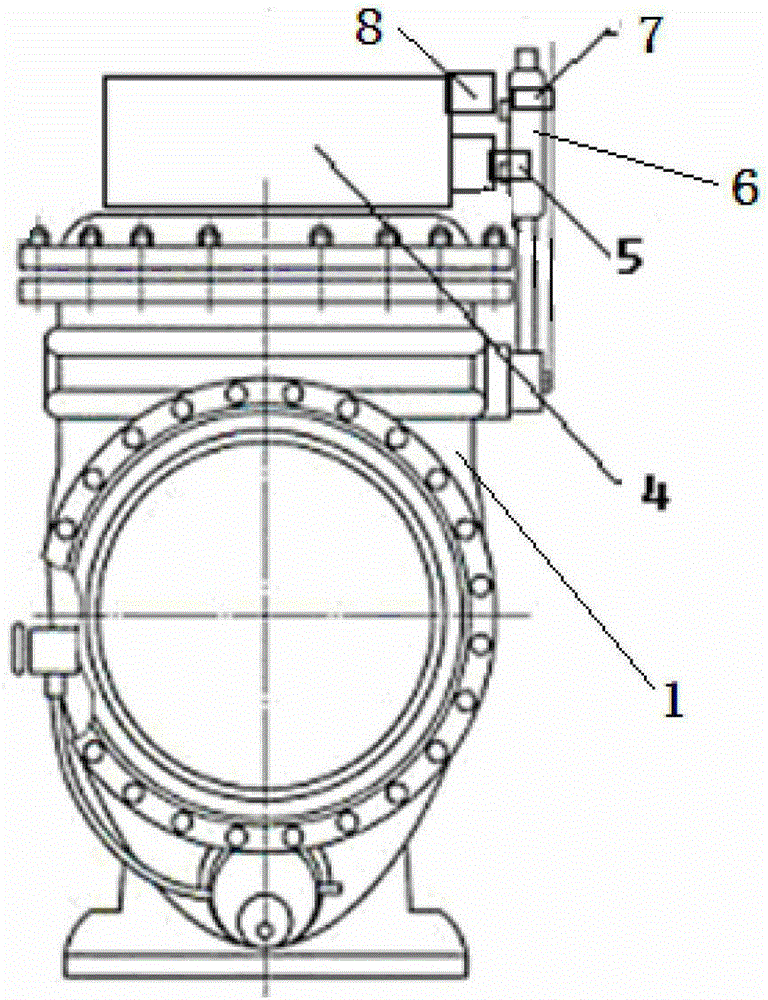

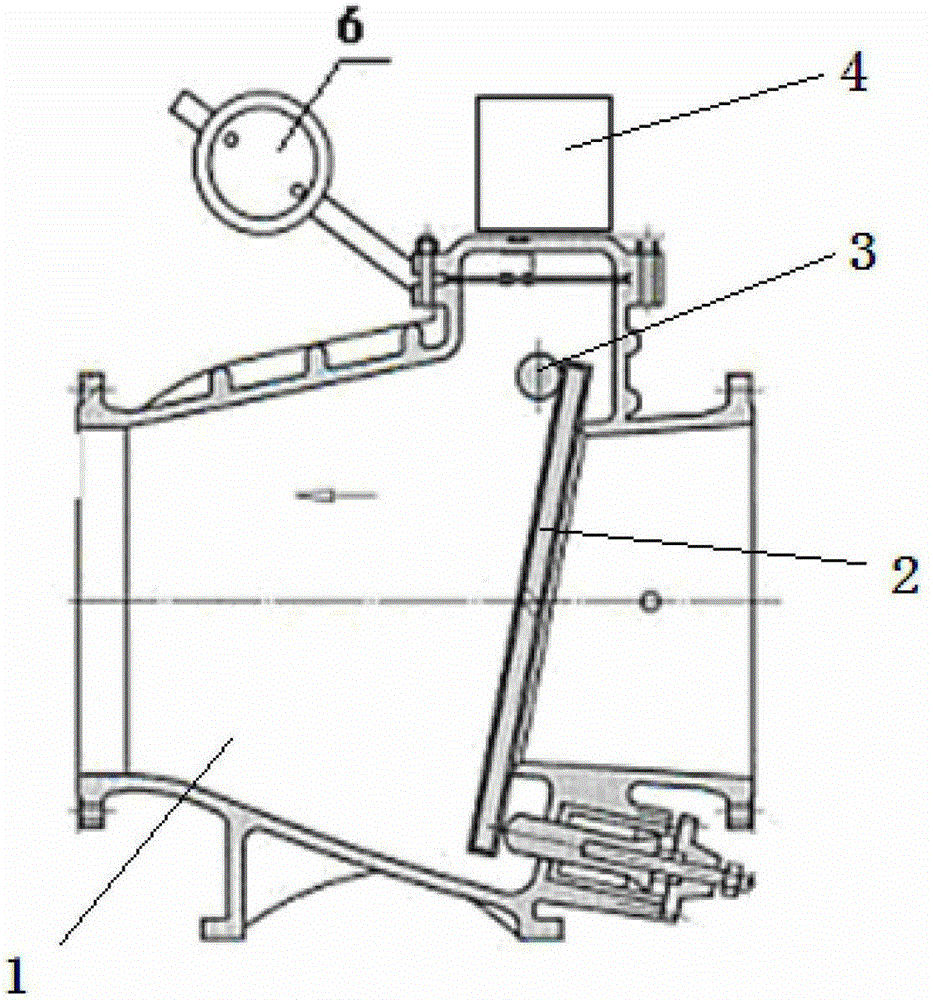

[0017] like figure 1 Shown is the structural representation of the gas pipeline check valve of the present invention; figure 2 Shown is a cross-sectional view of the gas pipeline check valve of the present invention. The gas pipeline check valve of the present invention includes a valve body 1 and a valve disc 2, the valve disc 2 closely cooperates with the inner sealing surface of the valve body 1, the valve disc 2 is fixedly connected with a rotating shaft 3, and the rotating shaft 3 is hinged on the valve body 1 And the other end extends out of the valve body 1 and is connected with a rocker 6 for opening or closing the valve clack 2. The rotating shaft 3 is in sealing fit with the hinge of the valve body 1, and also includes a valve for limiting the position of the valve clack 2 after the valve clack 2 is opened. The limiting device includes a transmission mechanism 4 fixed on the valve body 1 and a stopper 5 arranged at the lower end of the rocker 6 and used to limit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com