Tension detection device of leather

A technology for tension detection and leather, which is applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of leather fixing and stretching direction inaccuracy, lack of accuracy of tension detection data, and insufficient force Uniformity and other issues to achieve the effect of avoiding distortion, uniform force, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

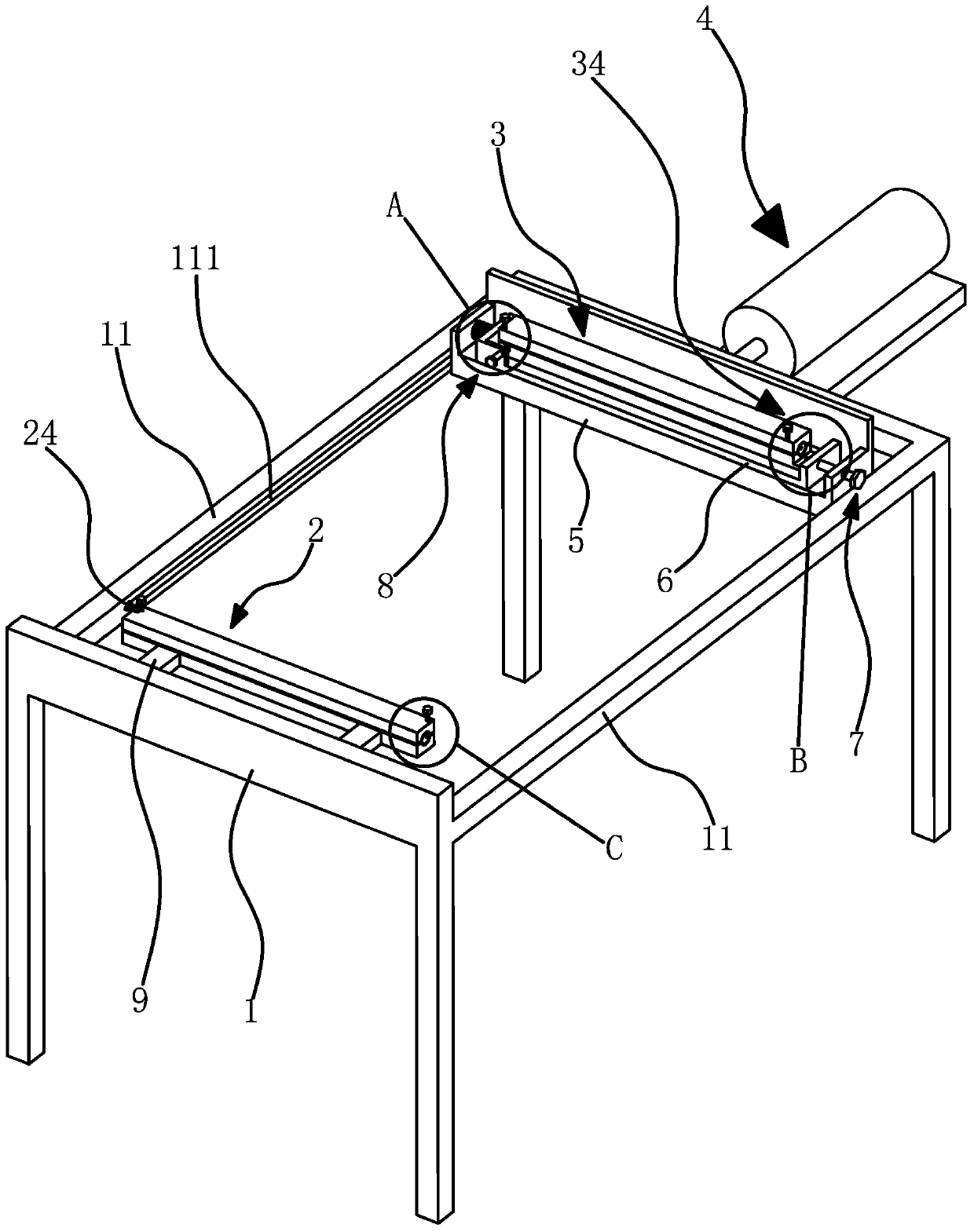

Method used

Image

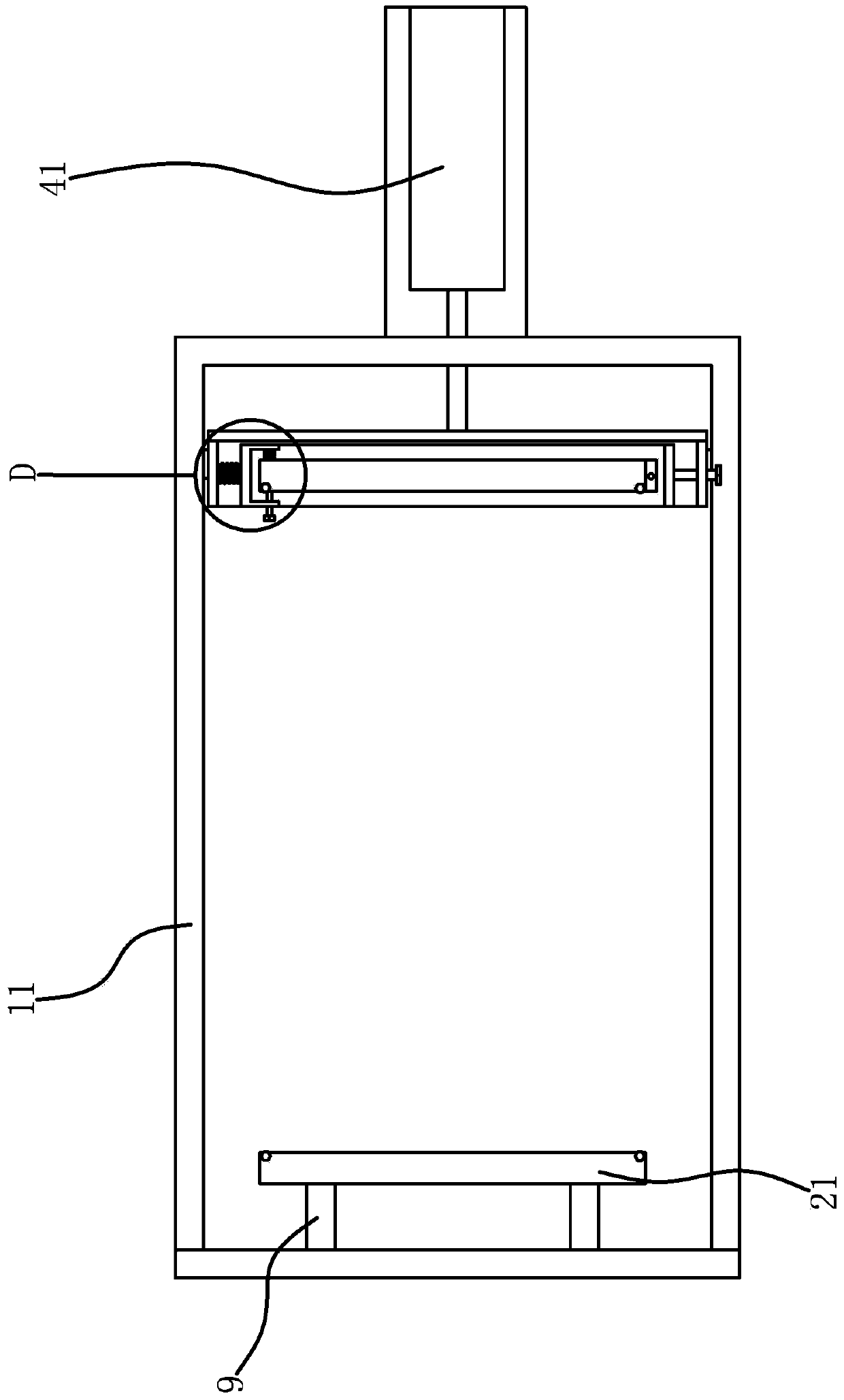

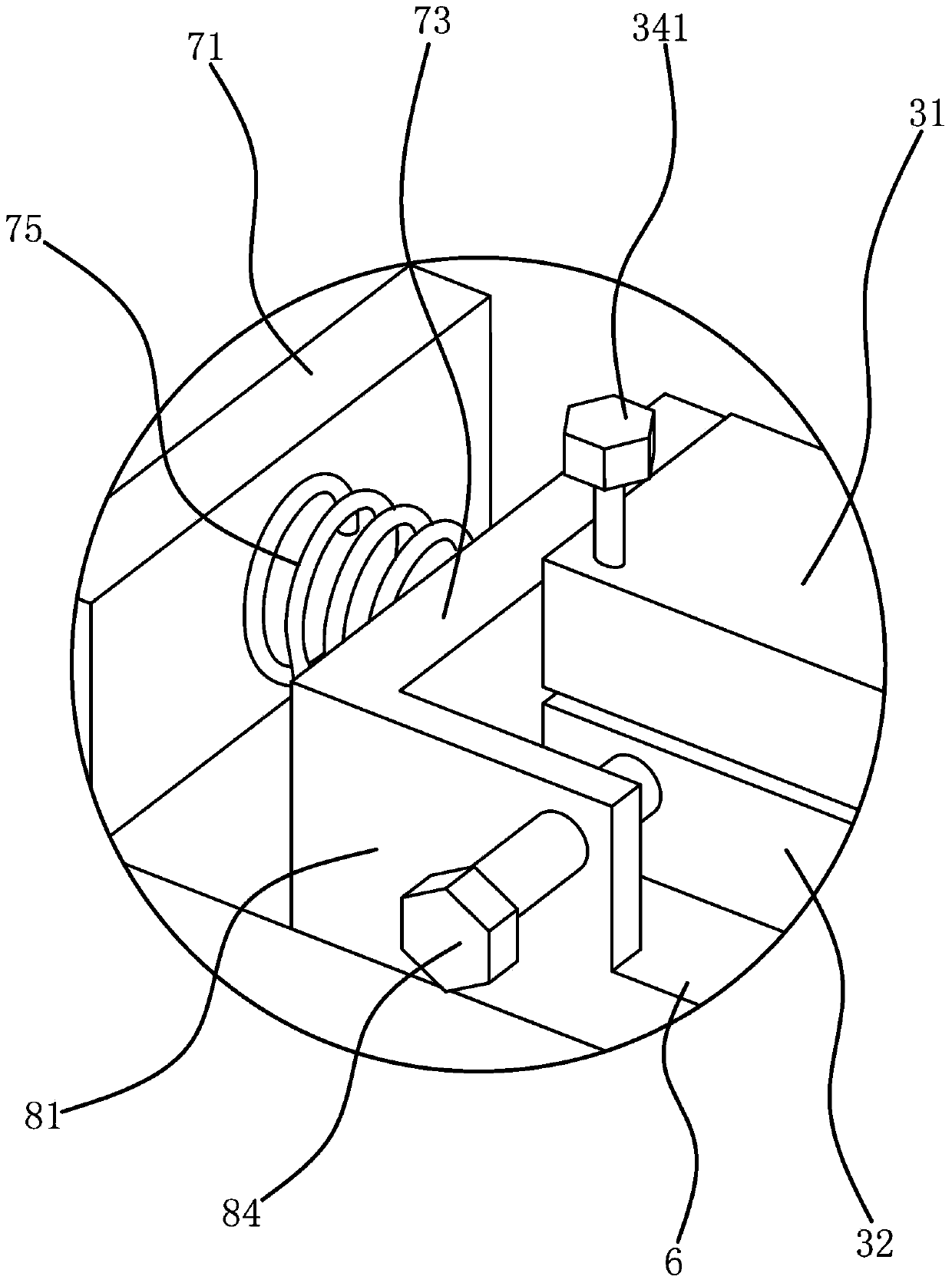

Examples

Embodiment 2

[0035] The structure of the tension detection device of the leather is basically the same as that of Embodiment 1, the difference is that Figure 7 As shown, the power mechanism 4 includes a screw rod 45, which is rotatably connected to the frame 1. The length direction of the screw rod 45 is perpendicular to the length direction of the lower clamping rod 22, and a connecting block 46 is fixedly connected to the lower side of the slide plate 5. A threaded hole is offered on the connection block 46, and one end of the screw rod 45 is screwed in the threaded hole, and the other end is fixedly connected with a driven pulley 43, and the frame 1 is also provided with a motor 42, and the output shaft of the motor 42 is fixedly connected with a The driving pulley, the driving pulley and the driven pulley 43 are connected by a belt 44, the control motor 42 drives the main pulley to rotate, and then drives the screw rod 45 to rotate through the belt 44, because the screw rod 45 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com