Methods of manufacturing optical sheets, organic light emitting display devices having optical sheets, and methods of manufacturing organic light emitting display devices having optical sheets

An optical sheet, an organic technology, applied in optics, optical components, semiconductor/solid-state device manufacturing, etc., can solve the problem of reducing image quality, achieve the effect of improving quality and reducing color shift phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0075] According to an exemplary embodiment, the optical sheet 240 including the transparent patterns 245 and the light scattering patterns 250 arranged alternately and repeatedly may be obtained without performing any patterning process. In addition, the light scattering layer 210 includes an adhesive 220 so that an additional adhesive layer may not be required.

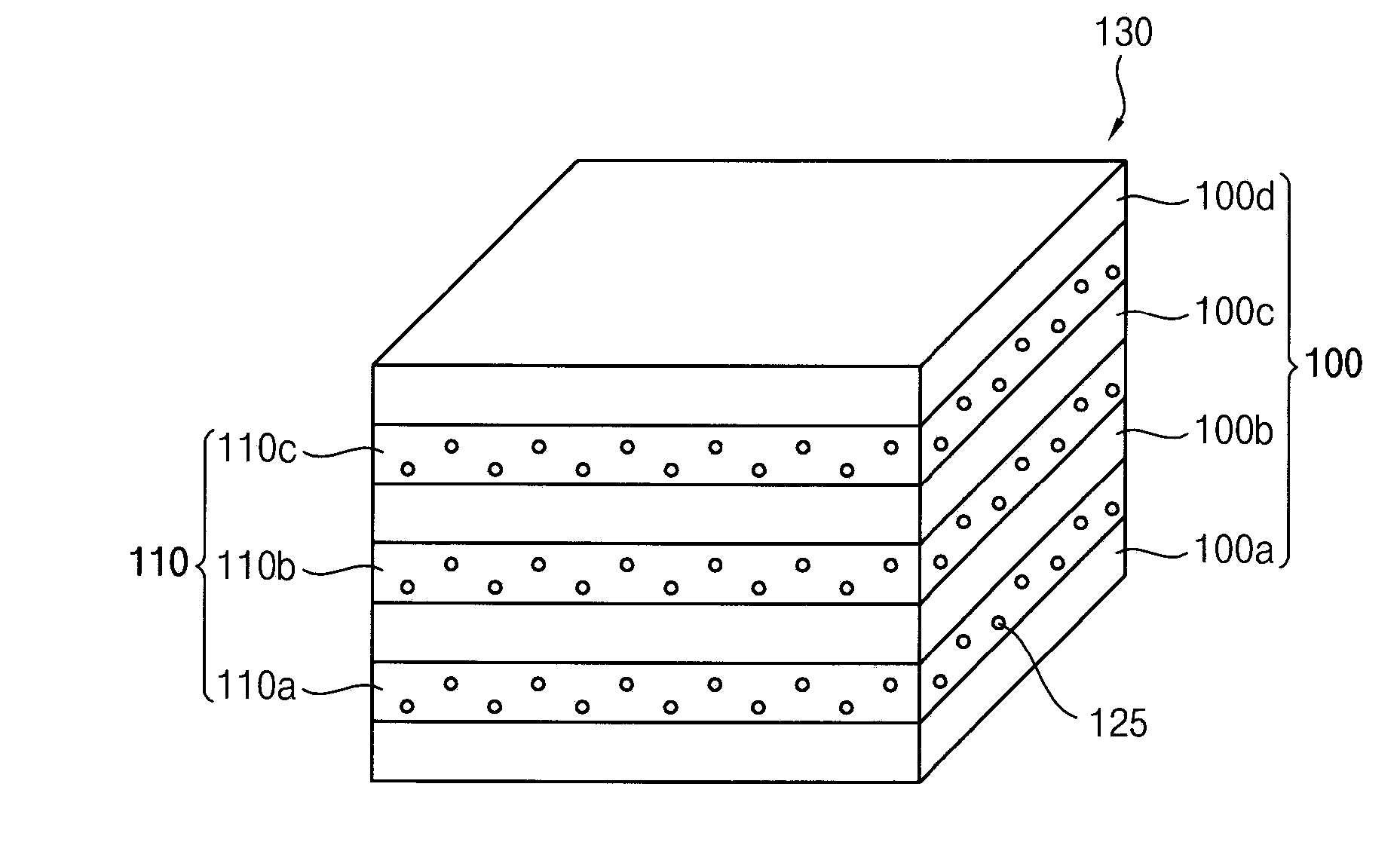

[0076] Figure 9 to Figure 12 is a perspective view illustrating a method of manufacturing an optical sheet according to other exemplary embodiments.

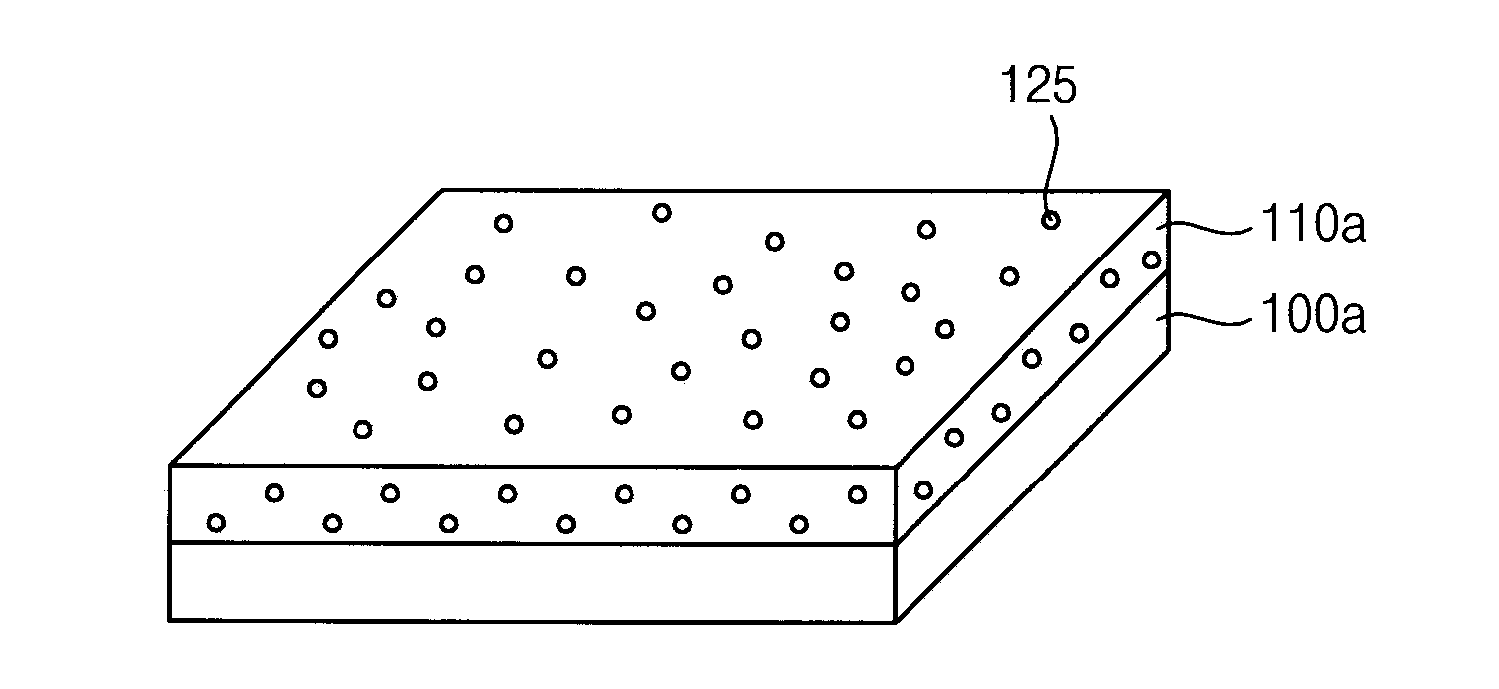

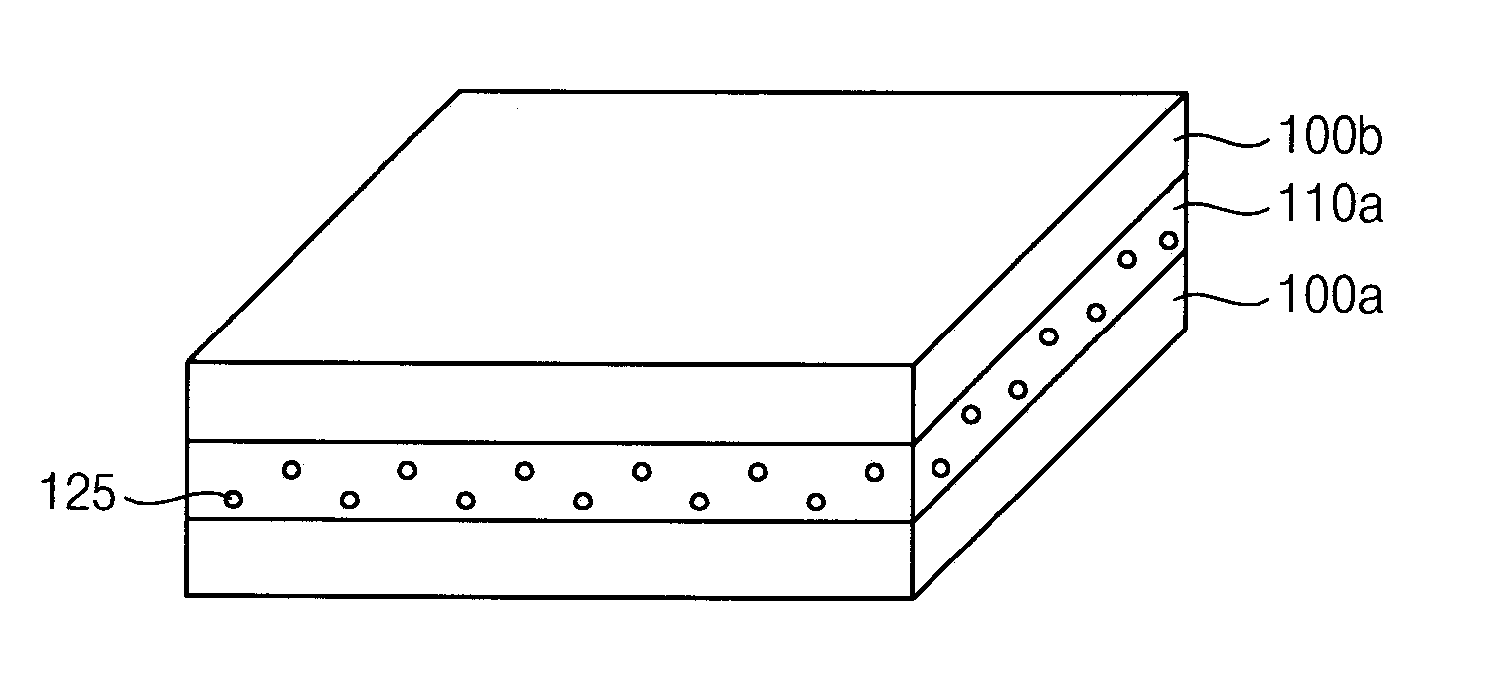

[0077] refer to Figure 9 , the transparent layer 300 and the light scattering layer 310 may be alternately and repeatedly stacked.

[0078] The transparent layer 300 and the light-scattering layer 310 may respectively include and refer to image 3 The materials of transparent layer 100 and light scattering layer 110 are described as substantially the same or substantially similar materials. The process of arranging the transparent layer 300 and the light scatter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com