High-power microwave testing platform

A high-power microwave and test platform technology, applied in the microwave field, can solve the problems of bulky test platform, increase the difficulty of installation and operation, increase the difficulty of test platform processing, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11625

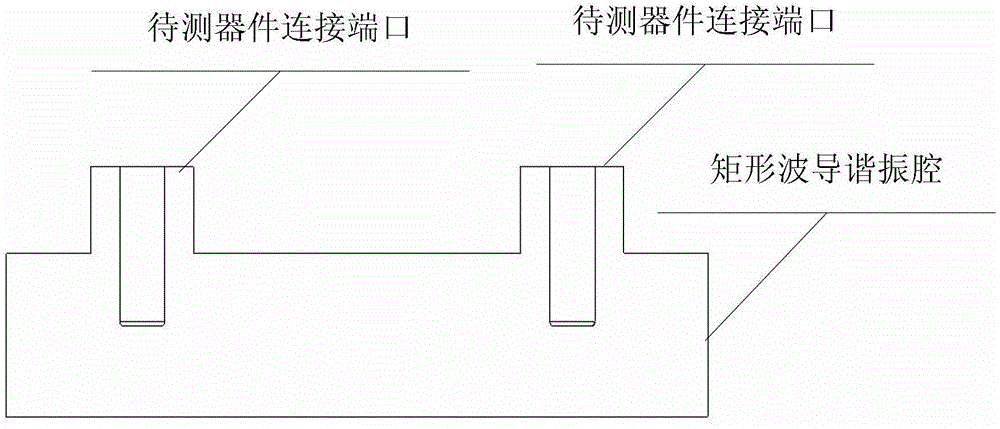

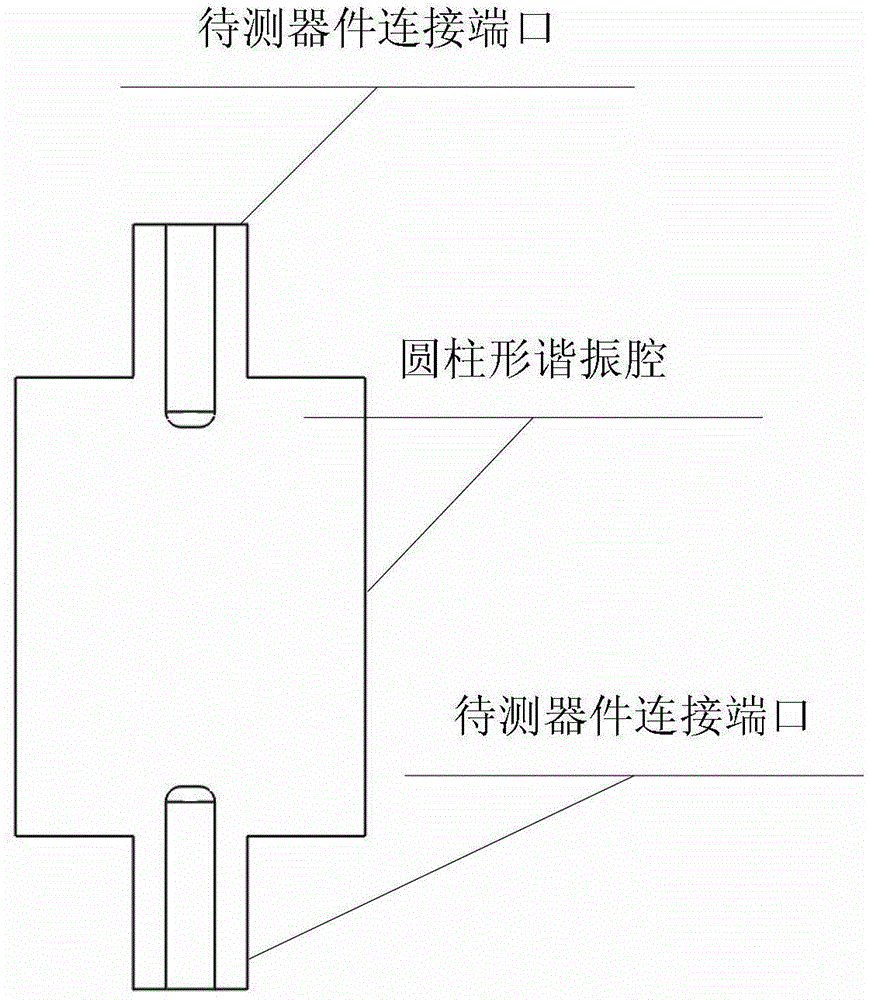

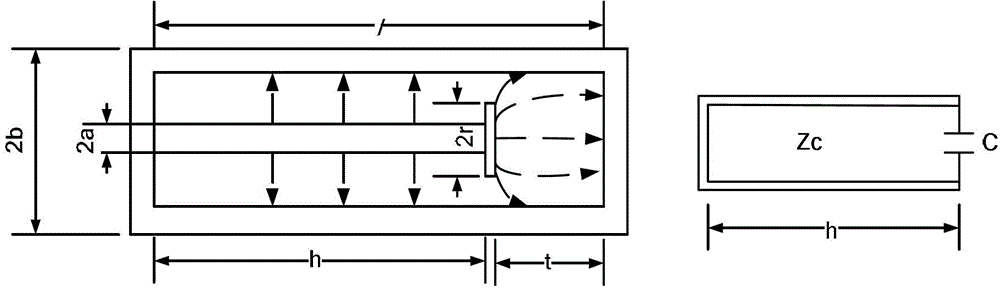

[0052] Example 116 2.5MHz High Power Input Coupler Test

[0053] According to the specific implementation methods of the above four points, the test platform was designed and processed, and the test of the 162.5MHz high-power input coupler was completed. The basic physical structure dimensions of the test platform are as follows: a=100mm; b=200mm; r=180mm; l=180mm; h=145mm. The outer conductor of the two devices under test—"162.5MHz high-power input coupler" is connected to the large straight tube 6 at the connection port of the device under test through flange sealing, and the inner conductor is connected to the small straight tube 7 at the connection port of the device under test through Plug structure tight fit connection. The measured VSWR of the entire test platform is less than 1.1, which better meets the requirements of power matching transmission; the power test level reaches 20kW continuous wave, which meets the power design index of the device under test.

Embodiment 2325

[0054] Example 2325MHz High Power Input Coupler Test

[0055]According to the specific implementation methods of the above four points, the test platform was designed and processed, and the test of the 325MHz high-power input coupler was completed. The basic physical structure dimensions of the test platform are as follows: a=100mm; b=200mm; r=180mm; l=180mm; h=80mm. The outer conductor of the two devices under test—"325MHz high power input coupler" is connected to the large straight tube 6 at the connection port of the device under test through a flange sealing connection, and the inner conductor and the small straight tube 7 at the connection port of the device under test are connected through a plug Plug structure tight fit connection. The measured VSWR of the entire test platform is less than 1.1, which satisfies the requirements of power matching transmission; the power test level reaches 10kW continuous wave, which meets the power design index of the device under test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com