Polyurethane resin encapsulation-based DBR fiber laser hydrophone

A technology of polyurethane resin and fiber laser, which is applied in the direction of instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effect of convenient reuse and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

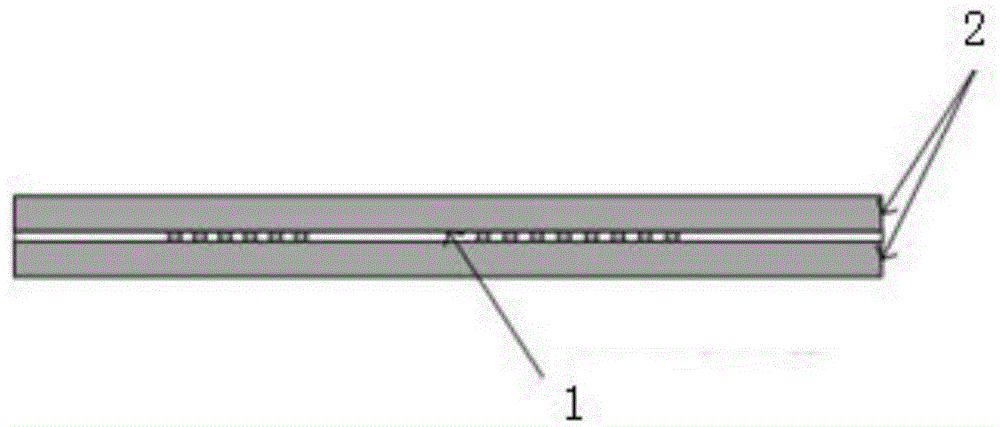

[0013] Such as figure 1 As shown, the high-sensitivity hydrophone given in the present invention is a single longitudinal mode polarization heterodyne sensor based on DBR fiber laser 1 encapsulated by polyurethane resin 2 . The test device for detecting low-frequency underwater acoustic signals of KHz and below by using the hydrophone as a sensing unit also includes a signal processing unit and a signal demodulation unit.

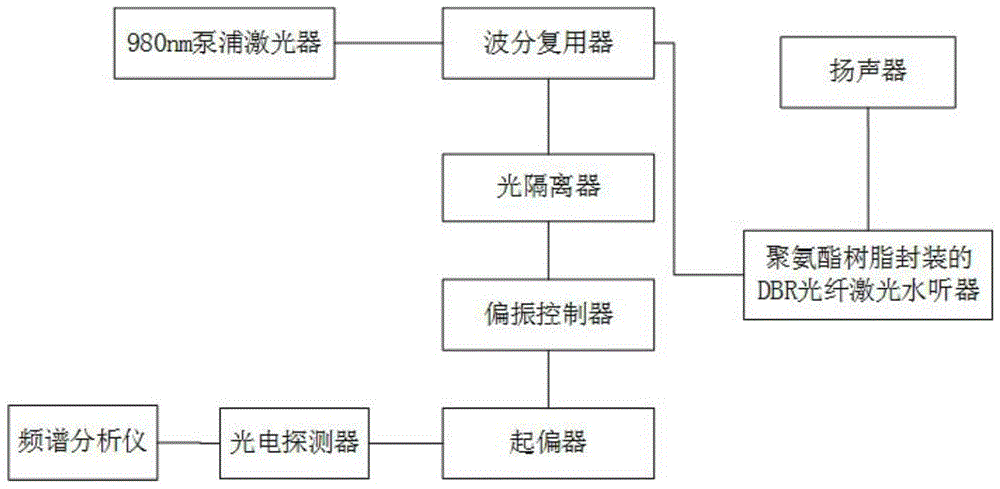

[0014] Such as figure 2 As shown, the signal processing unit includes a 980nm laser, a 980 / 1550nm wavelength division multiplexer, an optical isolator, a polarization controller, a polarizer, and a photodetector; the signal demodulation unit is a spectrum analyzer.

[0015] The working principle is roughly as follows: the 980nm laser is used as the pump light source, and the 980nm port of the wavelength division multiplexer enters the 980nm / 1550n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com