Method for reclaiming acetic acid from waste water containing dilute acetic acid

A recovery method and technology of dilute acetic acid, applied in separation methods, separation/purification of carboxylic acid compounds, adsorption water/sewage treatment, etc., can solve the problems of unsatisfactory effect, uneconomical, low recovery rate, etc., and achieve high recovery rate , the effect of reducing pollution and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

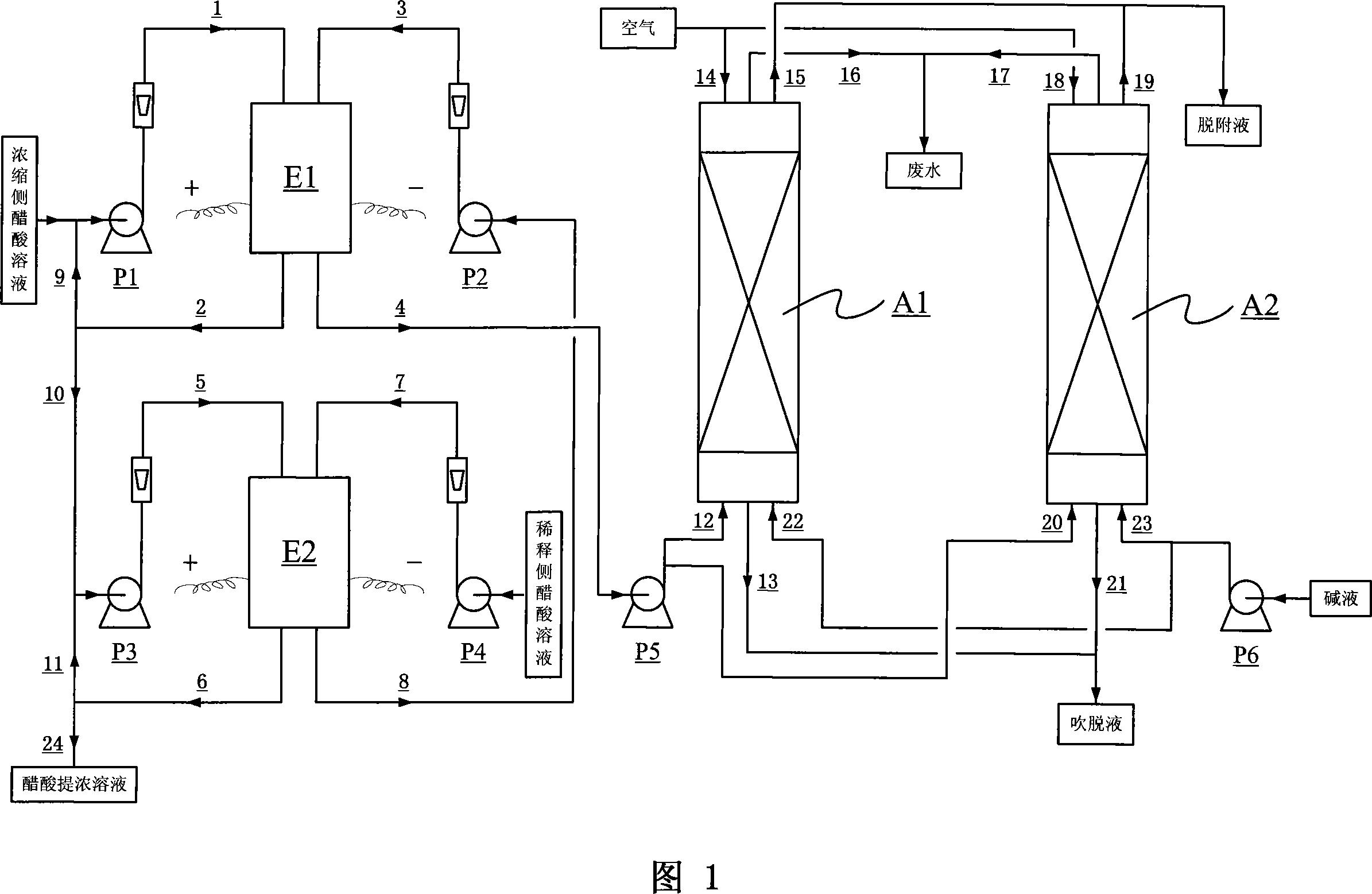

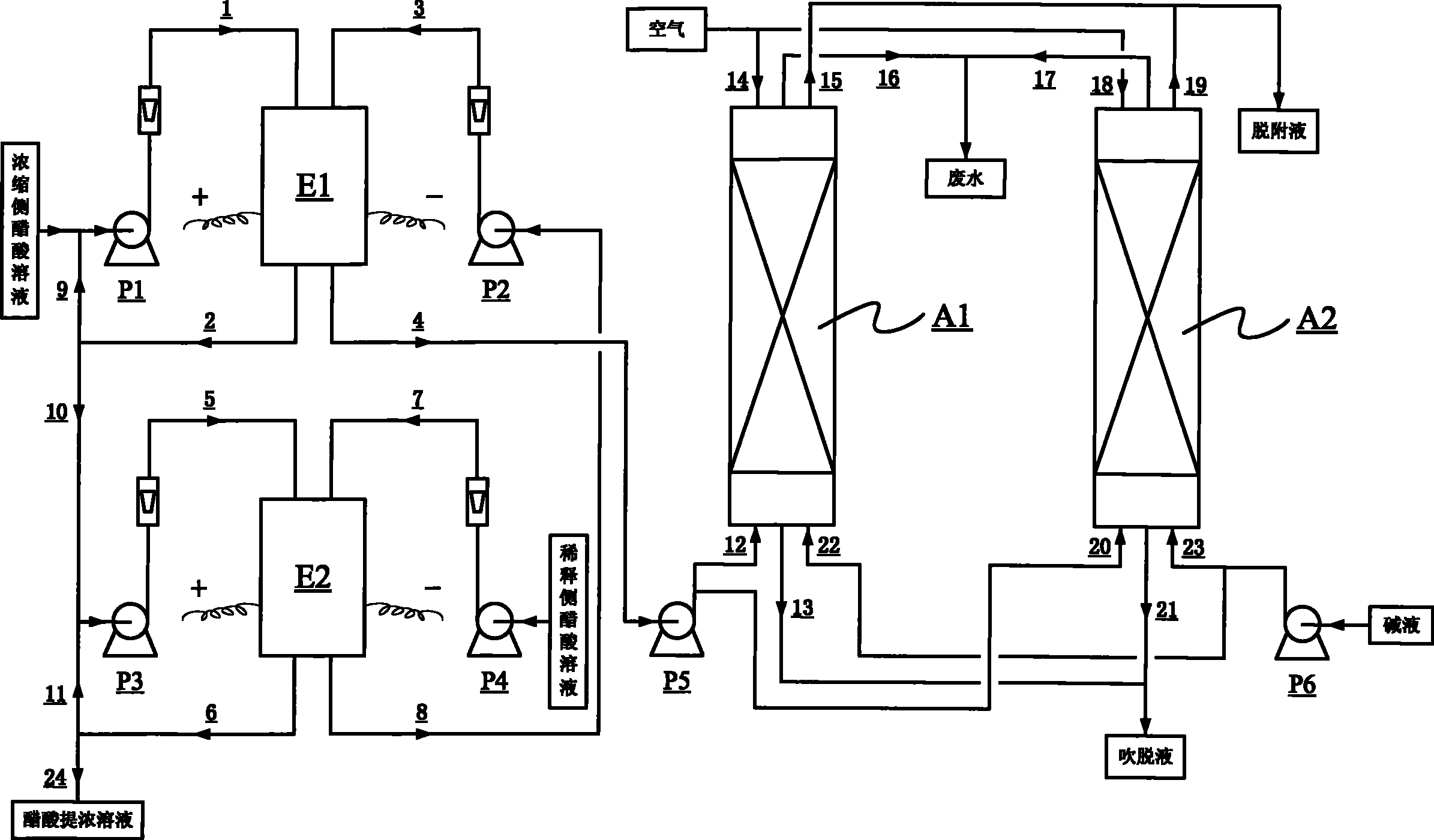

[0015] The invention combines the electrodialysis method and the resin adsorption method, and first uses the electrodialysis method to reduce the acetic acid content in the waste water, and then uses the anion resin adsorption method to further remove the remaining acetic acid, so that the recovery rate of the acetic acid is increased and the power consumption is greatly reduced.

[0016] Specifically, the weight percentage of acetic acid in wastewater containing dilute acetic acid is generally not more than 5%. The present invention uses electrodialysis to treat and recycle the acetic acid in this type of wastewater to reduce the concentration of acetic acid to below 1000ppm, and then use anion The resin adsorption method further removes the remaining acetic acid, which can reduce the concentration of acetic acid in the final discharged wastewater to below 50ppm.

[0017] According to the technical scheme of the present invention, the liquids on the diluting side and concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com