Melon beating machine capable of automatically spraying water

A melon machine and automatic technology, which is applied in the field of melon machines, can solve the problems of increased operating costs, low cleanliness of melon seeds, and the need to improve the efficiency of separation operations, so as to achieve high operating efficiency, novel and reasonable machine structure, and small resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

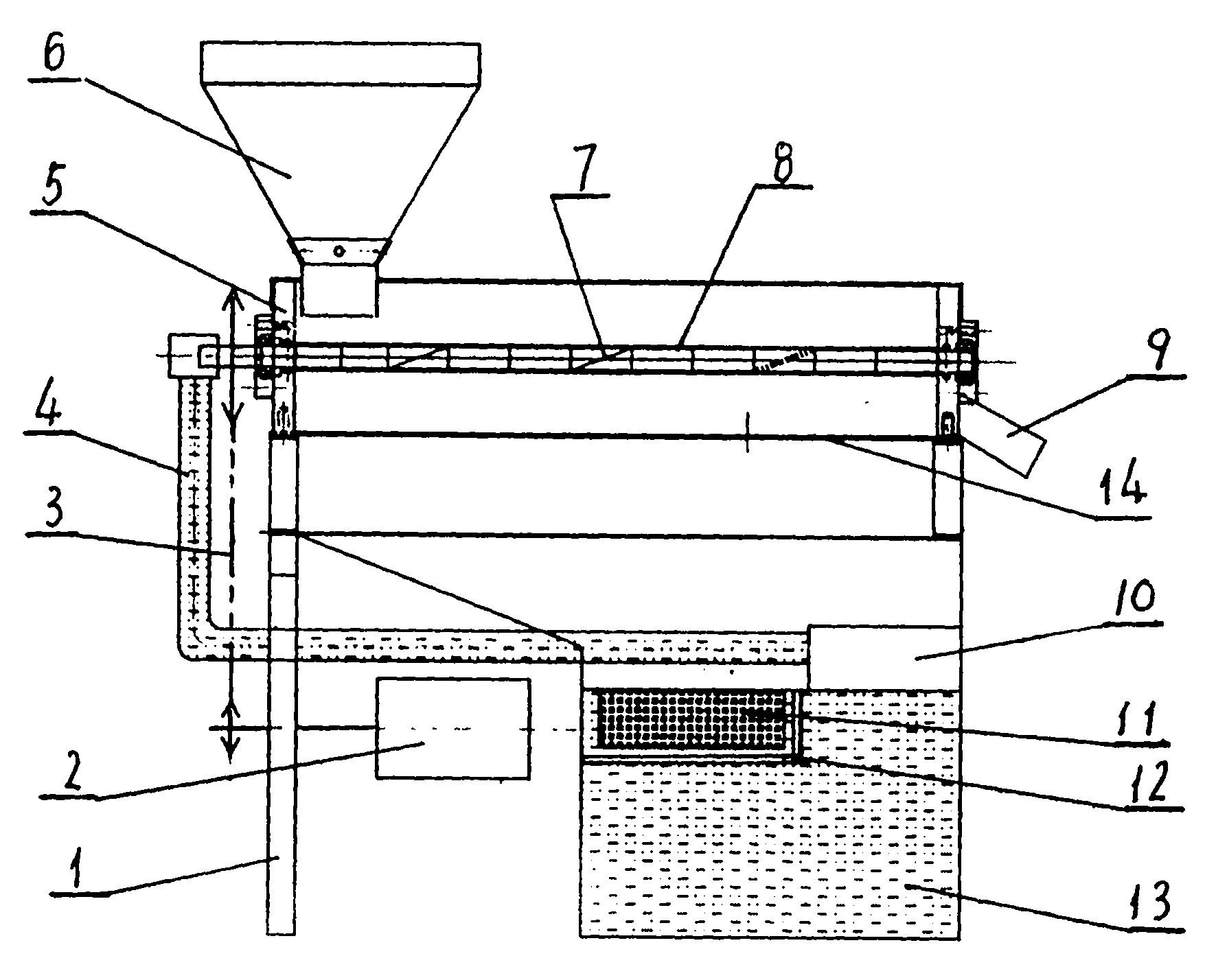

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An automatic water-spraying melon machine, on the upper part of the frame 1, a cover plate assembly 5 and a screen piece 14 are installed sequentially from top to bottom, on the cover plate assembly 5, between the cover plate assembly 5 and the screen piece 14 The hollow shaft 8 is rotatably assembled at the middle part, and the melon-beating blades 7 are arranged on the outer surface of the hollow shaft 8 according to the helical line, and the water outlet hole is set on the shaft wall of the hollow shaft 8, and the feeding hopper 6 and the melon seed outlet 9 are respectively arranged on the feeding end and the discharging end of the cover plate assembly 5, and the motor 2 and the water tank 13 are arranged under the screen 14, and the chain drive system 3 connects the motor 2 to the hollow shaft 8, and on the water tank 13 The side interior is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com